ViTrox V510i Automatic Inspection

AI Powered technology for smart, easy & quality programming

- Designed for various size of PCB assemblies to increase production efficiency and cost savings for electronic manufacturing services, communication industry, and etc.

- V510i 3D AOI system is a next generation solution for the SMT line, offering the powerful 3D inspection capabilities.

- AI Powered technology for smart, easy & quality programming.

- Competitive Cost of Ownership

Breakthrough Technologies

AI-Based Smart Technologies

AI Smart Programming

- Intelligent & automated programming which eliminates human skills dependency & rapidly improve the programming speed

- IPC Class Compliance on Algorithm & Parameter

- AI Smart programming assures algorithm quality, accuracy & consistency

AI Assist Buy Off in Repair Station

- With the AI Smart Assist feature, the inspection results buy off process can be done at faster speed and higher accuracy.

- With AI Smart Assist, it helps to eliminate human judgment mistake.

- This new innovation AI feature is fitting the Smart Manufacturing needs as Centralized VVTS buy-off station.

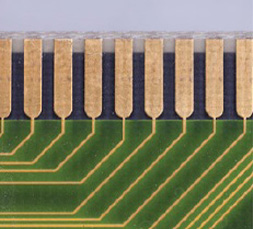

Unique and Universal Algorithms for Unconventional Applications

ViTrox AOI system is designed for general SMT and also capable of covering other unique inspection requirements such as Gold finger, Coordinate Measurement & Surface Defects Detection.

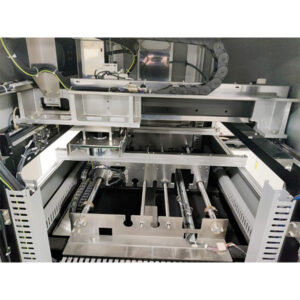

Largest Board Size Platform

ViTrox V510i Automatic Inspection

Minimum and Maximum Panel Size

127mm x 127mm – 1320.8mm x 1320.8mm

Minimum and Maximum Panel Thickness 1.5mm to 10mm

Maximum Panel Weight 25Kg

The smart V510i XLW AOI solution offers the world-class board inspection capabilities and software compatible with Industry 4.0 for quality-assured inspection results. With its latest capability, the largest and heaviest PCB board weighing up to 25kg and up to 1.3m x 1.3m (length x width) in size can be accommodated and inspected.

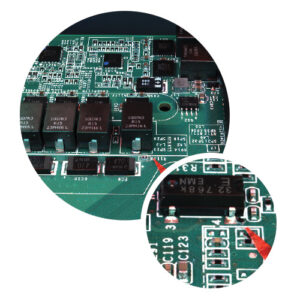

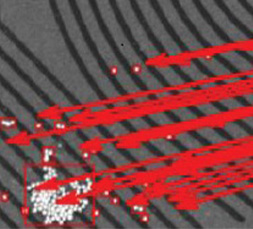

SPECKLE Auto Mapping Technology (SAM)

Processes auto mapping on component’s lead for side angle inspection.

Ready for Industry 4.0

Equipped with essential communication protocol for Industry 4.0.

Algorithm-Driven Inspection

Algorithm-driven inspection in side view cameras.

Adaptive Lighting

Smart lighting on required inspection direction

| Model.No | V510i SE |

| Inspection Functions | Missing, Offset, Skewed, Polarity, Billboard, Tombstone, Lifted/Bent Leads, Excess/Insufficient Solder, Overturn, Bridging, Wrong Part (OCV Marking), Pin Through Hole (Solderability & Pin Detection), Package Coplanarity, Lifted Lead (Height Measurement), Foreign Material Detection, Polarity Dimple Measurement |

| Board Level Tracebility | Camera-Read Barcodes; External Barcode Reader Configured; OCR Capability with Batch Code Logging |

| Operating System | Windows 10 Pro (64 bit) |

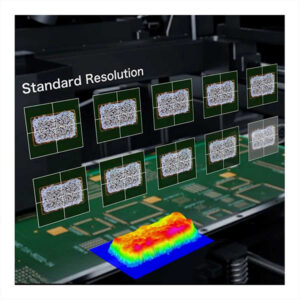

| Optical Resolution & FOV Size | 12MP CoaXPress Camera Default: 60mmx45mm * 15µm telecentric lens Option: 53mmx39mm * 13µm telecentric lens Option: 32mmx24mm * 8µm telecentric lens |

| Inspection Speed | 12MP @ 15μm resolution: up to 64cm²/sec |

| 3D Technologies | Phase Shift Profilometry’s (PSP) Methodology with 4-way projectors |

| Lighting Module | Multiple Color, Multiple Angle, Multiple Segment LED Lighting Head, Auto Calibration Concurrent Lighting Module |

| Conveyor Width Adjustment | Auto Width Adjustment; Bottom-Up Clamping; In-line SMEMA |

| Power Supplies | 100-120 V, 16A / 200-240V, 8A Single Phase |

| Air requirement | N/A |

| System footprint (Width X Depth X Height) | 1060mmx1303mmx2000mm |

| Total system weight | ~830kgs |

| Maximum PCB Size (L x W) | FDL: 510mmx250mm (20”x9.8”) Single Lane: 510mmx540mm (20”x21.2”) |

|

| Minimum PCB Size (L x W) | 50mmx50mm (2”x2”) | |

| Maximum PCB Inspectable Area (L x W) | FDL: 510mmx243mm (20”x9.5”) Single Lane: 510mmx533mm (20”x20.9”) |

|

| Maximum PCB Thickness | 4mm (0.16″) | |

| Minimum PCB Thickness | 0.5mm (0.02″) | |

| Maximum PCB Weight | 3KG | |

| Top Clearance of PCB | 50mm | |

| Bottom Clearance of PCB | 100mm | |

| PCB Edge Clearance | 3.5mm | |

| PCB Transport Height | 875mm-965mm | |

| PCB Temperature | Ambient operating temperature is ~5⁰C to 40⁰C, maximum PCB temperature 80⁰C. | |

Reviews

There are no reviews yet.