KOKI Low Melting Point Solder Paste

Low Melting Point Lead Free Solder Paste T4AB58-M742

- Solder alloy composition is Sn0.4Ag57.6Bi

- Koki no-clean LEAD FREE solder paste

- T4AB58-M742 Sn0.4A57.6Bi

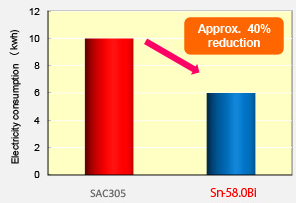

Energy-saving

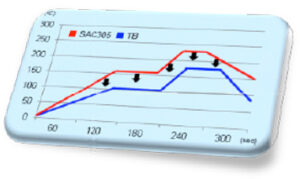

By reducing the required reflow profile temperature, electricity consumption can be reduced by approximately 40% compared to SAC305.

Reduction of electricity consumption results in reduction in CO2 emissions, achieving both energy saving and environmental care.

■ Electricity consumption / hr.during reflow process(kw)

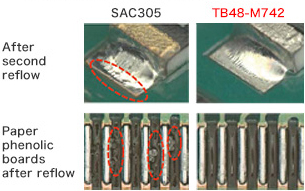

Reduces thermal damage to components and substrate

Energy saving is not the only benefit of a low temperature reflow profile.

A low temperature profile reduces thermal damage to components during double-sided reflow and allows for use of heat-sensitive paper phenolic substrates.

■ Joint conditions after reflow

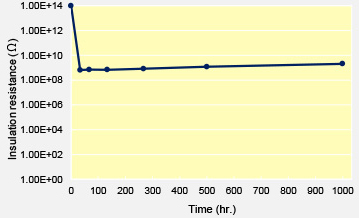

High insulation reliability

The flux solvent volatilizes even in low temperature reflow, eliminating reduction in insulation resistance arising from inadequate volatilization.

TB48-M742・T4AB48/58-M742 produces flux residue with high insulation reliability.

■ Voltage applied SIR

KOKI Low Melting Point Solder Paste

Solder alloy composition is Sn0.4Ag57.6Bi

- PERFECT MELTING and wetting at super fine pitch (>0.4mm pitch) and micro components (>0.3mm dia CSP, 0603 chip).

- Specially formulated flux chemistry ensures extremely LOW VOIDING with CSPs and broad contact area components.

- Conforms to Halogen-free standard (Cl+Br = Less than 1500ppm) BS EN14582.

- Low melting point (138ºC )

| Application | Printing – Stencil | |

| Product | T4AB58-M742 | |

| Alloy | Composition (%) | Sn0.4A57.6Bi |

| Melting point (°C) | 138 | |

| Shape | Spherical | |

| Particle size (μm) | 20 – 38 | |

| Flux | Halide content (%) | 0 |

| Flux type | ROL0 | |

| Product | Flux content (%) | 10.0±1.0 |

| Viscosity*1 (Pa.S) | 190±30 | |

| Copper plate corrosion | Passed | |

| Tack time | > 16 hours | |

| Shelf life (below 10°C) | 6 months | |

Reviews

There are no reviews yet.