ViTrox 3D Solder Paste | V310i SE Inspection Machine (SPI)

V310i SE Inspection Machine (SPI) | Advanced 3D Solder Paste

- Preferred choice by consumer, automotive, and telecommunication sectors.

- Powerful reporting for data analysis and performance monitoring.

- High Speed performance SPI system in market.

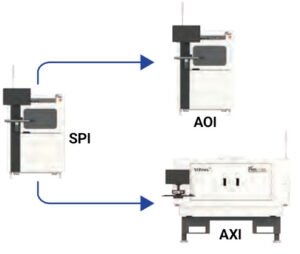

- Real-Time Closed Loop System Connectivity

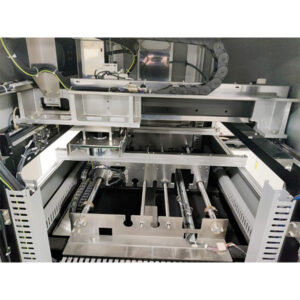

V310i Inspection Machine (SPI)

V310i SE Advanced 3D Solder Paste Inspection

Shareable wear & tear spare parts between 3D AOI and 3D SPI under one similar machine.

Advanced 3D Solder Paste Inspection Solution for Your SMT Inspection Needs.

V310i Advanced 3D Solder Paste Inspection System (SPI) solution.

High Speed performance SPI system in market.

Competitive Cost of Ownership.

Smart Manufacturing Ready.

Advanced Process Optimization

Collaborate with market known printer and pick & place partners. ViTrox AI profiles out the best printer settings for each production model. This is achieved through continuous data collection on printer optimization activities.

V310i Inspection Machine (SPI)

The V310i Series offers powerful technologies and high throughput productivity for SMT production line

Real-Time Closed Loop System Connectivity

Integrate with all ViTrox family inspection systems to create a closed-loop communicated ecosystem to maintain and improve production process efficiency, yield, and quality. Achieved through model parameter sharing and single-learning-multiple-machine linkages to minimize programming time.

| Model.No | V310i SE | |

| Inspection Functions | Missing, XY Offset, Solder Height, Solder Area, Solder Volume and Bridge. | |

| Board Level Tracebility | Camera-Read Barcodes; External Barcode Reader Configured | |

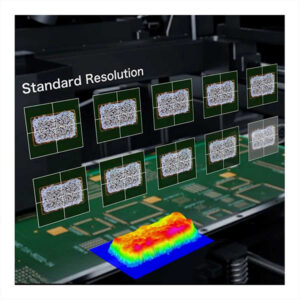

| System Hardware | 12 MP 4 MP | |

| Operating System | Windows 10 Pro (64 bit) | |

| Optical Resolution & FOV Size | Default: 60mmx45mm @ 15µm telecentric lens Option: 53mmx39mm @ 13µm telecentric lens Option: 32mmx24mm @ 8µm telecentric lens |

Default: 40mmx40mm @ 20µm telecentric lens |

| Inspection Speed | 12MP CoaXPress @ 15µm Resolution: Up to 94cm²/sec

12MP CameraLink @ 15µm Resolution: Up to 60cm²/sec |

4MP CameraLink: 40~53cm²/sec |

| 3D Technologies | Phase Shift Profilometry’s (PSP) Methodology | |

| Lighting Module | Concurrent Lighting Module | |

| Conveyor Width Adjustment | Auto Width Adjustment; Bottom-Up Clamping; In-line SMEMA | |

| Installation Specification | ||

| Power Supplies | 100-120 V, 16A/200-240V, 8A Single Phase | |

| Air requirement | N/A | |

| System footprint (Width X Depth X Height) | 1060mmx1303mmx2000mm | |

| Total system weight | ~830kgs | |

| PCB Dimension | SE | FDL |

| Maximum PCB Size (L x W) | 510mmx540mm (20”x21.2”) | Single Lane: 510mmx450mm (20”x17.7”) DL Equal: 510mmx250mm (20”x9.8”) |

| Minimum PCB Size (L x W) | 50mmx50mm (2”x2”) | 50mmx50mm (2”x2”) |

| Maximum PCB Inspectable Area (L x W) | 510mmx533mm (20”x20.9”) | Single Lane: 510mmx443mm (20”x17.4”) DL Equal: 510mmx243mm (20”x9.5”) |

| Maximum PCB Thickness | 4mm (0.16″) | 4mm (0.16″) |

| Minimum PCB Thickness | 0.5mm (0.02″) | 0.5mm (0.02″) |

| Maximum PCB Weight | 3kg | 3kg |

| Top Clearance of PCB | 50mm | 50mm |

| Bottom clearance of PCB | 100mm | 100mm |

| PCB Edge Clearance | 3.5mm | 3.5mm |

| PCB Transport Height | 875mm-965mm | |

| PCB Temperature | Ambient operating temperature is ~5⁰C to 40⁰C, maximum PCB temperature 80⁰C. | |

| Brand |

ViTrox |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.