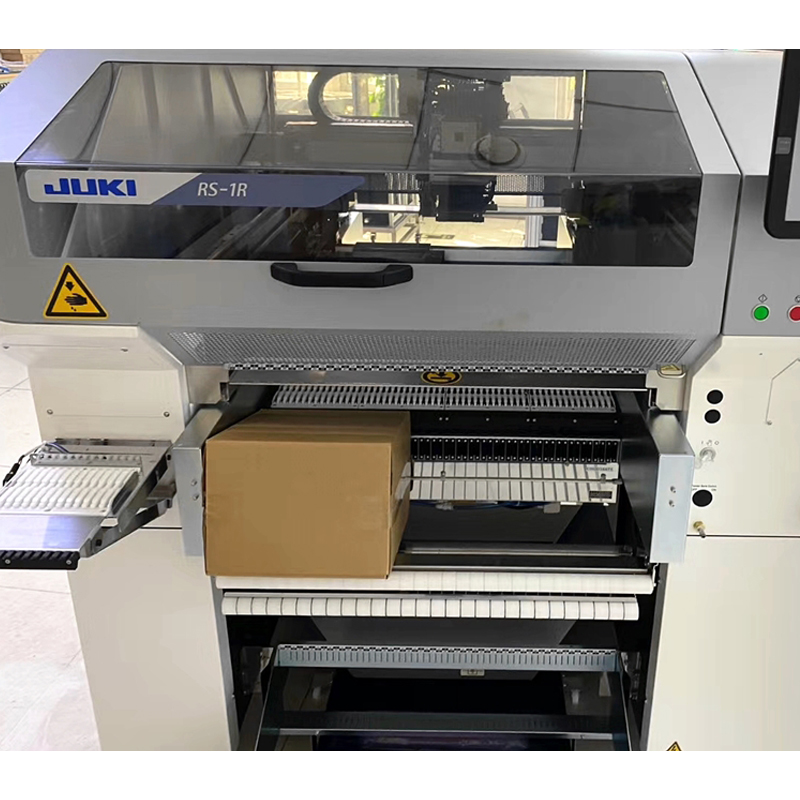

RS-1R | SMT-JUKI Fast Smart Modular Pick and Place Machine

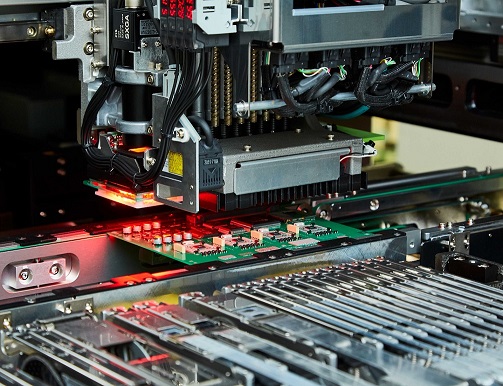

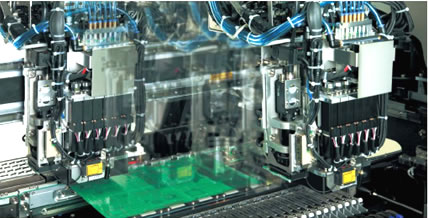

Next Generation Smart Fast Modular Mounter

RS-1R | SMT-JUKI

JUKI RS-1R consistent further development of the tried-and-tested technologies from opens up new, outstanding possibilities:

The unique Takumi head covers even more different component heights and thus achieves a decisive speed advantage. The 360 ° visual component recognition allows the secure detection of user-specific polarity marks. Thanks to the RFID integration in the nozzles, these can be traced back completely together with the components and boards. The machine combines the features of a chip shooter with a mounter for large components. The purchase of each special machine type for it eliminates as well as a change of the placement head.

Class leading speed, up to 47,000 CPH

- Juki RS-1R Maximum speed of up to 47,000 cph*.

- This is made possible by a revolutionary head design that reduces the travel time and distance for every placement.

Optimal for LED placement

- RS-1R can use either vision or laser centering for diffusing lenses, depending on the component requirements. High-precision placement of diffusion lenses.

- A wide range of lens styles can be placed.Up to 650 x 370mm with single clamping. LED chip Conveyor direction 2nd clamp placement area

- Long PCB Support Up to 950 x 370mm with dual clamping, or up to 1200 x 370mm with optional conveyor extensions.

Self-Optimizing Smart Head

- “Takumi head” that automatically optimizes it’s height between 6 different positions based on component height. Tact time is optimized by keeping the head as close to the PCB as possible for the components placed.

JUKI RS-1R

- Class leading speed, up to 47,000 cph

- Newly developed “Takumi Head” with changing recognition sensor height

- Optimum line balance and highest throughput

- Wide component range from 0201 (metric) to large connectors and ICs

- Optimal for LED placement

| RS-1R | SMT-JUKI Fast Smart Modular Pick and Place Machine | |||||

|---|---|---|---|---|---|

| Model | JUKI RS-1R | ||||

| Conveyor specification | standard | 150mm conveyor extensions, upstream and downstream |

250mm conveyor extensions, upstream and downstream |

||

| Board size | minimum | 50×50㎜ | |||

| maximum | 1 buffer | 650×370 ㎜ (Single clamping) | |||

| 950×370 ㎜ (double clamping) | 1,100×370 ㎜ (double clamping) | 1,200×370 ㎜ (double clamping) | |||

| 3 buffers | 360×370㎜ | 500×370㎜ | 600×370㎜ | ||

| Component height | 25㎜ | ||||

| Component size | 0201*1 ~□74 ㎜ /150×50 ㎜ | ||||

| Placement speed | Optimum | 47,000CPH | |||

| IPC9850 | 31,000CPH | ||||

| Placement accuracy | ±35μm(Cpk≧1) | ||||

| Vision recognition | ±30μm | ||||

| Feeder inputs | max.112*2 | ||||

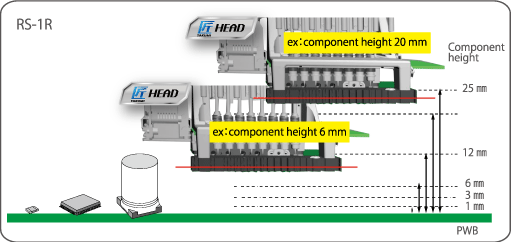

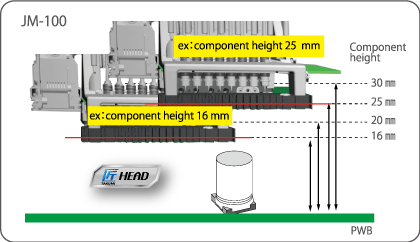

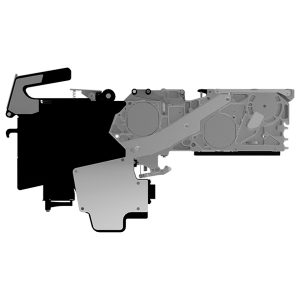

Takumi head

JUKI RS-1R Feature

Feature 1 Automatic height change of recognition sensor

“The 8-nozzle “”Takumi head”” automatically changes the laser sensor height according to the height of component that to be centered.

Various components from ultra-small component to large component can be optimally placed with best tact time.

RS-1R: 6 levels (1, 3, 6, 12, 20, 25 mm) can be selected arbitrarily.

JM-100: 4 levels (16, 20, 25, 30 mm) can be selected arbitrarily.”

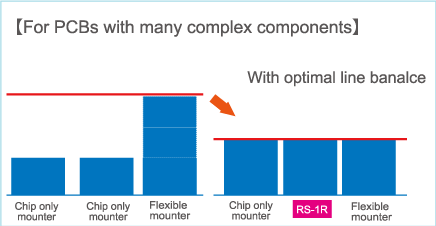

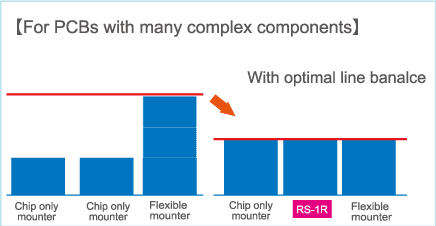

Feature 2 Optimum line balance and highest throughput

JUKI RS-1R Changing functionality does not require head replacement. The revolutionary design self-optimizes based on the production requirements. The RS-1R can reduce the workload on high speed. A line with two or more RS-1Rs can adjust to a wide variety of production requirements from high speed to high flexibility.

Features of the Laser Centering

JUKI’s original technology supports the high accuracy and high repeatability required for high density placement.

High accuracy, high-speed mounting

High-speed, on-the-fly centering

A high resolution laser is mounted on the head to center components in all directions including angle. Centering is done on-the-fly, allowing high speed placement of components from small chips to SOPs.

Adaptable centering

Centering accommodates component variations

Laser centering measures the components on the side. It is not affected by variations of component color or width/length so, unlike vision centering, there is no need to edit component data for different component vendors.

Component check function improves placement reliability

Since the laser is mounted on the head, it can be used to monitor the presence of components the entire time from pick to placement. This is difficult to accomplish with vacuum detection only. The placement reliability is also improved because the release of the component is confirmed after placement.

Flexibility

Vision centering technology

hod can be selected based on component type, shape, size and material. Laser centering is used for high speed placement of smaller components. Vision is used when lead or ball inspection is needed or when the component is too large for the laser. Many nozzles are available for odd-shaped components providing unsurpassed component handling.

hod can be selected based on component type, shape, size and material. Laser centering is used for high speed placement of smaller components. Vision is used when lead or ball inspection is needed or when the component is too large for the laser. Many nozzles are available for odd-shaped components providing unsurpassed component handling.

General Vision

General vision function is used to support a wide variety of today’s unusual vision centered components. After programming is complete, the data can be verified by picking and test centering a component.

Productivity

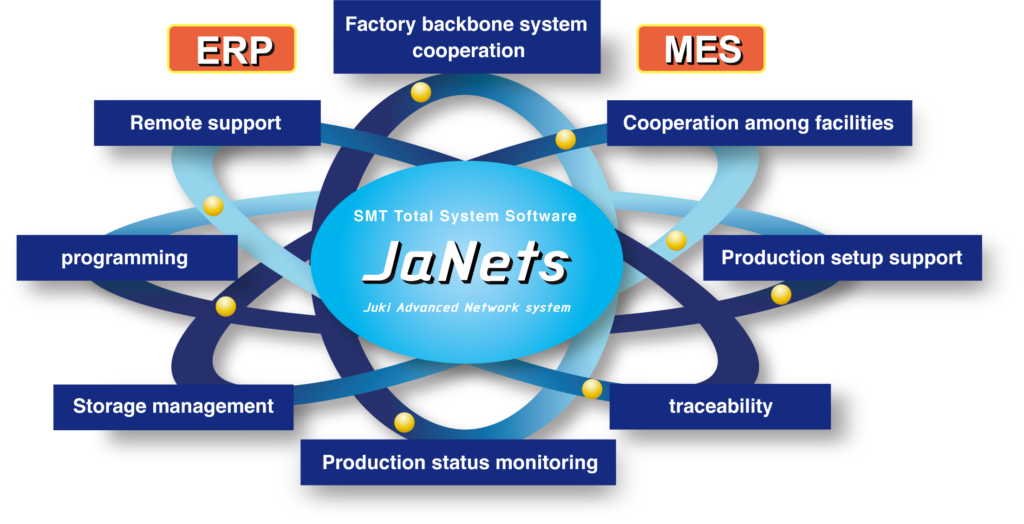

SMT Total System Software

JaNets

Calculate maximum placement speed. Line control software

Features

●Programming

Prepare and optimize production files

●Server manager DB

Programs and component data can be shared across multiple lines

●Analysis / optimization support software

Achieve stable operation by visualizing equipment status and performance

●External output function

Enables machine event status output with analysis and visualization reporting graphics. Supports IPC-CFX format.

●Line management function

- Production program download / upload to line

- Machine operation information / production information output function

- Multi-line management

- Individual machine production (switch programs sequentially from production completed machines)

- Program download / upload instructions by JaNets mobile *, machines Error notification

●System linkage between equipments

By adding Equipment Manager to Line Manager, it is possible to manage the entire line including printing machines and inspection machines.

- Printer/SPI program management

- Bad mark propagation

- Production management information and data output function

- Feed forward for printing misalignment* * Applicable models are RV series and RS-1 series

●ISM (storage tower) interface

- Automated line balancing and feeder position indication

( line / mounter / trolley, etc.) - Analyzes parts of mounter pick lists and determines priority of parts

picked based on FIFO, unique ID label date, parts manufacturing date,

and/or minimum required reel or tray quantities to meet the PWBA

production quantity. - Extraction in cluster units by combining parts lists

- Automated low level parts warning through JaNets

- For the remaining number of parts of the ISM server, subtract / update

the number of mounters used for the production of one board. - Highly accurate part counting including component miss-picks.

●Inuitive graphical displays to visualize and act on production data

Visualizes production progress, equipment operating status, errors, etc. at the production site, speeds up decision making, and supports optimal operation of the production line.

Reviews

There are no reviews yet.