WTBR 1000 – Benchtop Robot Soldering

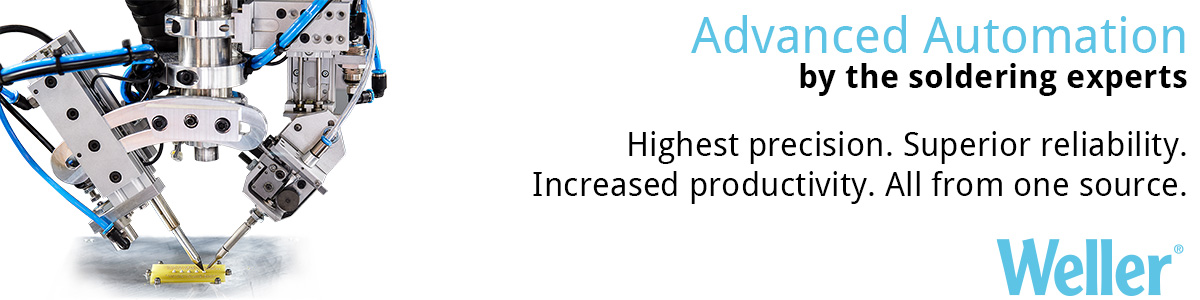

WTBR 1000 – Benchtop Robot Soldering is More than half a century of experience in soldering and superiority in innovation, allows us to take our customers to the next step in achieving production excellence. The new WTBR 1000 – Benchtop Robot Soldering represents a one-of-a-kind synergy of precision, reliability, and productivity of soldering tasks.

Highest soldering precision and superior reliability

![]() The WTBR 1000 is equipped with Weller‘s high performance Technology Line soldering tools, ensuring consistent quality of solder joints.

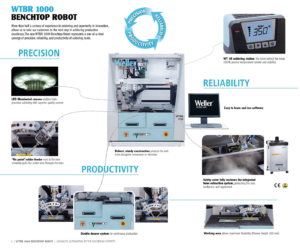

The WTBR 1000 is equipped with Weller‘s high performance Technology Line soldering tools, ensuring consistent quality of solder joints.

![]() The solder feeder is designed to be in close proximity to the workpiece (PCB), pulling the wire rather than pushing it through the feeder tube.

The solder feeder is designed to be in close proximity to the workpiece (PCB), pulling the wire rather than pushing it through the feeder tube.

![]() The robust and sturdy construction ensures that no sudden movements or vibrations negatively affect the workpiece, the components or the tools.

The robust and sturdy construction ensures that no sudden movements or vibrations negatively affect the workpiece, the components or the tools.

Maximizing productivity, lowering cost

![]() A double drawer system allows continuous production thereby providing much higher process throughput, improving productivity and offering flexibility.

A double drawer system allows continuous production thereby providing much higher process throughput, improving productivity and offering flexibility.

![]() The WTBR 1000 allows up to 50% cost saving versus hand soldering.

The WTBR 1000 allows up to 50% cost saving versus hand soldering.

Easy to learn and use software

![]() The WTBR 1000 is operated with easy to learn and use software, enabling operators to start using the unit comfortably and quickly.

The WTBR 1000 is operated with easy to learn and use software, enabling operators to start using the unit comfortably and quickly.

![]() It is easy to switch from one operator to another, with minimum time lost and without unnecessary training expenses.

It is easy to switch from one operator to another, with minimum time lost and without unnecessary training expenses.

Fully-enclosed system offers triple protection

![]() Being a fully-enclosed system, with integrated fume extraction, the WTBR 1000 Benchtop Robot allows our customers to achieve the highest level of safety: protecting the operator, the workpiece (PCB) and the machine.

Being a fully-enclosed system, with integrated fume extraction, the WTBR 1000 Benchtop Robot allows our customers to achieve the highest level of safety: protecting the operator, the workpiece (PCB) and the machine.

![]() The fully-enclosed system provides a complete and CE-compliant solution to the customer

The fully-enclosed system provides a complete and CE-compliant solution to the customer

Reviews

There are no reviews yet.