SEHO GoWave | Automatic Soldering

SEHO GoWave | Automatic Soldering

- The wave soldering system GoWave is a powerful soldering system for those just entering into mass-soldering operations.

- The system is suited for electronic productions with small or medium-sized volumes and also provides an economic solution for universities, schools and laboratories.

- A special feature of this machine is its compact, but performance-oriented design.

- It therefore allows an economical, automatic wave soldering process at simultaneously low costs.

SEHO GoWave

SEHO GoWave | Automatic Soldering

Compact – but with the Technology of Large Systems

The design of the GoWave provides the same basic technology found in SEHO’s large wave soldering machines.

The GoWave is a powerful soldering system for those just entering into mass-soldering operations. This system is suited to a variety of applications ranging from entry-level mass soldering to soldering in small or medium-sized batches. It also provides an economical soldering solution for universities, schools and laboratories. The GoWave is especially featured with its innovative nozzle concept which is ideally suited for nearly all soldering tasks. In addition, it may be equipped with a local nitrogen inertion in the soldering area in case of demanding applications.

GoWave presents the finest soldering technology in its class due to its advanced fluxer module, efficient preheater, innovative soldering area and microprocessor control.

Ideal for small production volumes, the Seho GoWave is suited for a variety of applications ranging from entry level mass soldering to soldering in small or medium sized batches.

Innovative HVLPTechnology

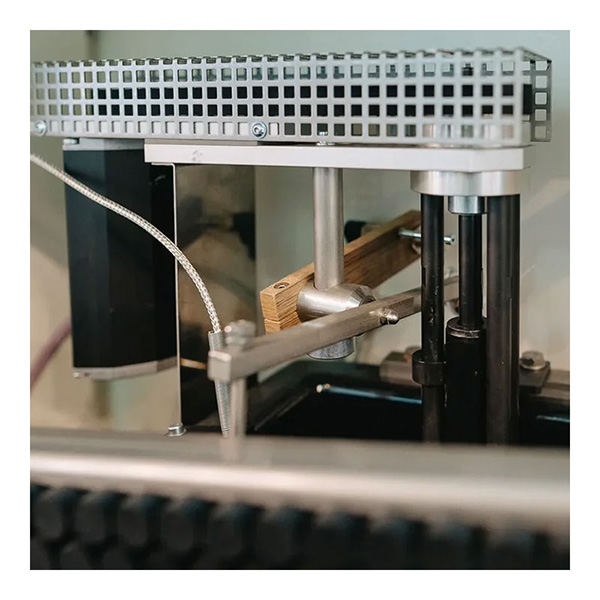

- The ATS spray fluxing module, developed by SEHO, has several advantages and is ideally suited for processing o low-solid fluxes.

- The spray head features HVLP technology (high-volume, low pressure) which generates atomization of the flux with a comparatively low pressure.This ensures a stable and repro-ducible spray jet with a very homogeneous spray pattern and an extremely good boundary at the outer edges to enable a remarkable reduction of the flux consumption.

- Overall, this low pressure system creates considerably less spray mist which results in a notable reduction of soiling in the fluxer area. As a result, maintenance requirements are mini-mized.

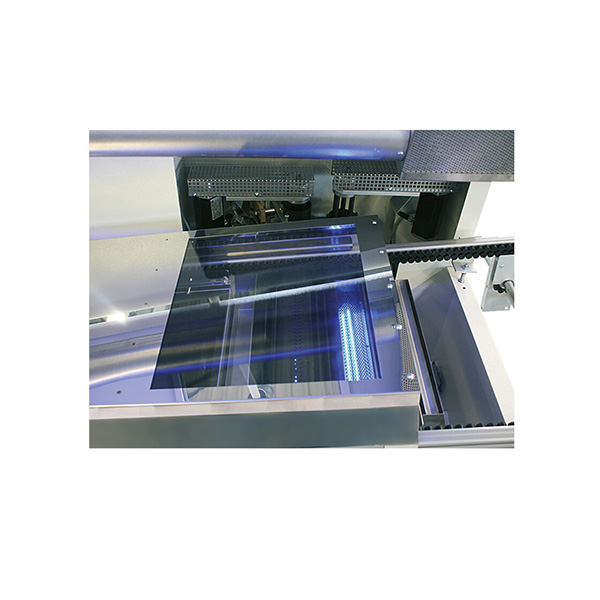

Powerful and Individually Adjustable

- The GoWave is featured with an infrared preheat zone with a total length of 700 mm and has a ceramic glass cover. The generous width of 400 mm ensures a very even and reproducible heating of even high-mass printed circuit boards.

- The preheat temperature is individually adjustable up to 420°C. Thus, the system is ideally suited for high temperature applications, such as lead-free soldering processes. Of course, the preheat area is separately controlled and monitored.

- The entire preheat and soldering area is covered with a re-flection tunnel. This enables a very high thermal stability and reduces energy consumption.

- To achieve a higher energy transfer especially when pro-cessing high mass printed circuit boards, the control unit may be programmed to stop the assemblies in the preheat zone.

Easy to Operate

- The integrated microprocessor control with touch screen makes for easy programming of the system and ensures re-producibility of all soldering processes.

- The control unit monitors all machine functions and reliably controls all key process parameters. With the possibility to save up to 100 soldering programs, the GoWave provides quick and easy change of parameter settings for soldering of different printed circuit boards.

- A USB data interface as well as recording of operating and process data ensures uncomplicated tracking and illustration of the processes.

Up-to-Date and Low Maintenance

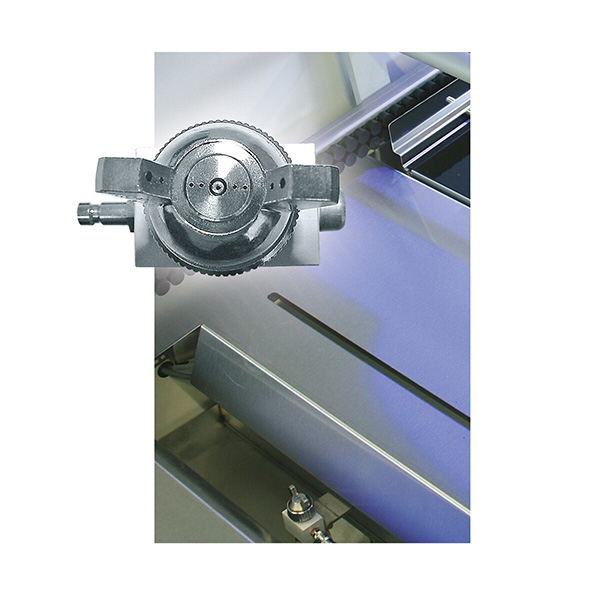

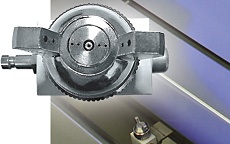

- The heart of the GoWave – the soldering area – is featured with a flexible configuration and therefore the system may be used for nearly all soldering tasks.

- As a standard, the solder pot is provided with a protective composit coating, developed by SEHO, which is ideally suited for processing leadfree solder alloys.

- The solder pot has a modest 185 kg (SnPb) capacity, ensuring low start-up costs and a short heat-up time which contributes to a low energy consumption and a remarkable reduction of the costs of ownership.

- Innovative solder nozzle geometries which may be used in a single wave or dual wave concept guarantee highest flexibili

- flexible and powerful with minimum footprint

- soldering width up to 340 mm

- flexible and robust conveyor system for processing of soldering frames

- efficient control unit

- easy and convenient operation with touch screen and USB interface

- precise CAN bus motors

- innovative fluxer area with HVLP technology (high volume – low pressure)

- powerful preheat with programmable stop

- up-to-date solder nozzle geometries

- 100 % lead-free capable

| Power | 230/400 V three-phase 50 Hz (standard) |

| Power | 8 kW |

| Wave width | 340 mm |

| The height of the elements | max 100 mm |

| The speed of transport | 0.3-2.0 m / min |

| External dimensions L x W | 3000×820 mm |

| Connecting the lift | 550 m³ / h (max 1 pc.) |

| The amount of solder | ~ 150 kg |

| Compressed air pressure | 6 bar |

| Brand |

SEHO |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.