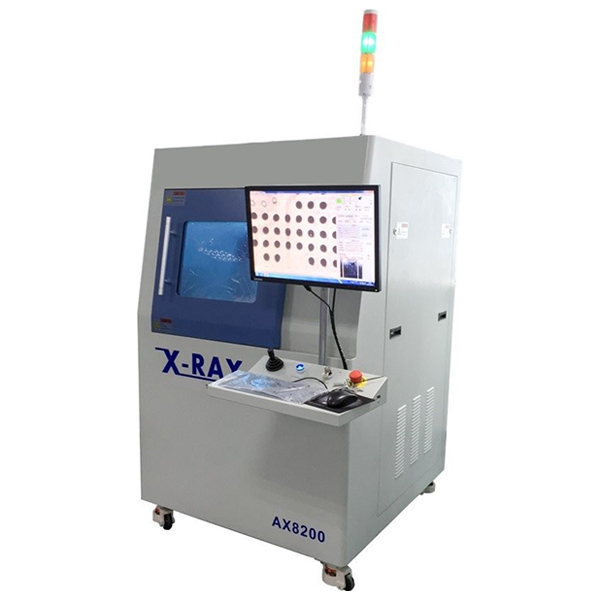

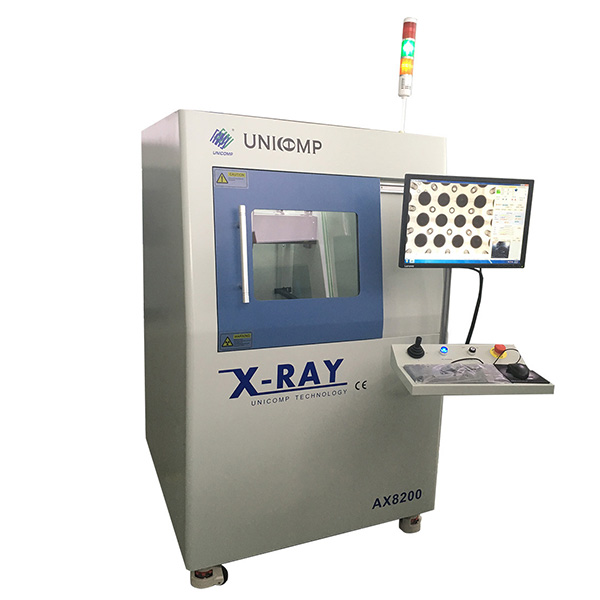

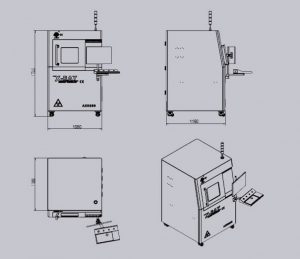

AX8200 – X-Ray Inspection Machine

AX8200 – X-Ray

A high-powered, closed tube X-Ray system with x600 magnification designed for fast diagnostic PCB inspection.

AX8200 X-Ray machine is designed to provide high resolution x-ray imaging primarily for the electronics industry. This versatile system is effective for many applications within the PCB manufacturing process. This includes BGA, CSP, QFN, Flip Chip, COB and the wide range of SMT components. The AX-8200 is a powerful support tool for process development, process monitoring and refinement of the rework operation. Supported by a powerful and easy to use software interface, the AX-8200 is capable of addressing small and large volume factory requirements

Features of this X-Ray Inspection:

● 100KV 5μm X-ray tube, image intensifier with 2 mega pixels CCD camera.

● 90KV 5μm X-ray tube, image intensifier with 2 mega pixel digital camera.

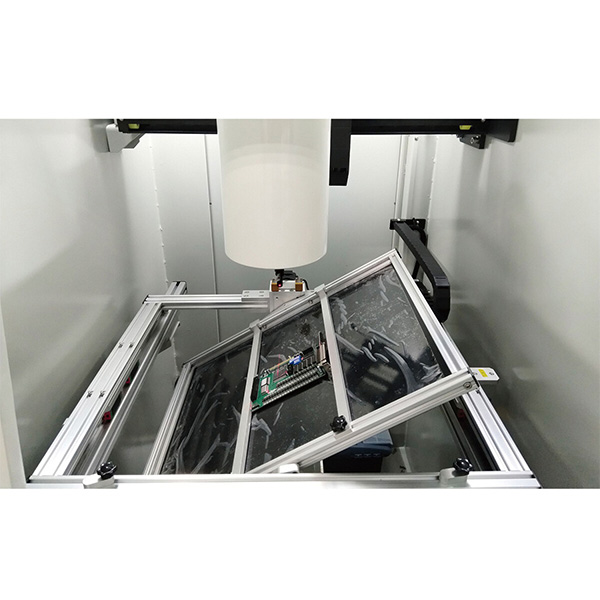

● Motion controls include: ±60° tilt motion, X/Y table motion plus Z axis tube and detector movement.

● Multi-function DXI image processing system

● X/Y programming function for multiple image inspection routines

● Max. loading area 510mm x 420mm, max. detection area 435 x 385mm with ~300X System Magnification.

BGA void/area auto-measurement plus report generation.

|

X-Ray tube max. voltage, type

|

90kV, closed |

| X-Ray tube power consumption | 8W |

| X-Ray tube focal spot size | 5µm |

| X-Ray tube motion range (up and down) | 150mm |

| X-Ray tube magnification | 600X |

| Detector intensifier | 4″/12″ (FPD optional) |

| Detector resolution | 77/110 LP/cm |

| Camera | 2 mega pixel CCD |

| Detector motion range (up and down) | 290mm |

| Max. loading area | 510 x 420mm |

| Max. inspection area | 435 x 385mm |

| Max. loading weight | 10kg |

| Machine dimensions | 1080 x 1180 x 1730mm (WDH) |

| Machine weight | 1050 kg |

BGA , CSP , LED , Flip Chip , Semiconductor,

Battery Industry , Small Metal Casting,

Electronic Connector Module,

Aerospace Components , Photovoltaic Industry,

Other Special Industries.

Reviews

There are no reviews yet.