Home » Products » SMT Line Machine » AOI / SPI Machines » VT-S1080 | OMRON Automation – PCB Inspection System

VT-S1080 | OMRON Automation – PCB Inspection System

VT-S1080 | OMRON Automation – PCB Inspection System

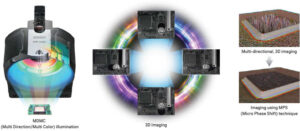

- Equipped with Omron’s own MDMC (Multi Direction/Multi Color) illumination and new MPS (Micro Phase Shift) technique, the system achieves highly robust*2 and reliable inspection performance.

Category: AOI / SPI Machines

Tags: AOI Incpection Machine, OMRON, VT-S1080

Description

VT-S1080 | OMRON Automation – PCB Inspection System

VT-S1080

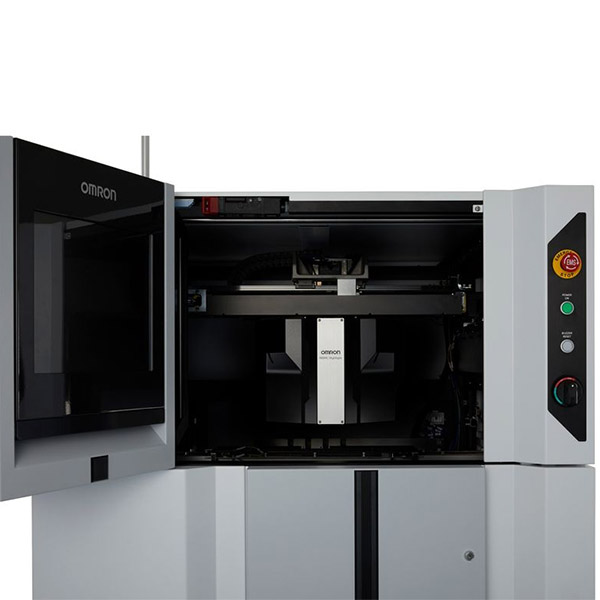

- The VT-S1080 is the world’s most advanced 3D AOI system, designed for maximum System Performance and High-Quality Productivity.

- Designed for flexible manufacturing, saving manpower with innovative AI Programming.

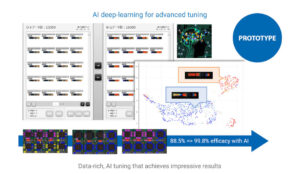

AI technology to minimize programming and visual inspection efforts

- Since values conforming to the standards are directly applied as inspection criteria, there is no dependency on the skill and expertise of the programmer.

- Minimization of programming efforts by quantitative inspection and AI-assisted qualitative inspection.

Equipped with Omron’s own MDMC (Multi Direction/Multi Color) illumination and new MPS (Micro Phase Shift) moiré technique, the system achieves highly robust*2 and reliable inspection performance.

2: Strong against noise that effects the judgement of inspection results such as shadows, secondary reflections, abnormal.

- First Pass Yield efficiency up to 99%

- AI-assisted qualitative inspection conforming to international standards

- AI technology to minimize programming and visual inspection efforts

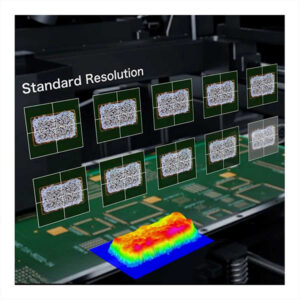

- Industry-first MDMC Illumination: 3D imaging from all angles enables accurate inspection of complicated solder shapes

- Elimination of Shadow and Secondary Reflection with 4-Direction MPS Projectors

- Realization of Solder Wetting Direction directly relating to IPC Standards

- Innovative AI tools that support skill-less labor-saving tuning

- Full 3D compliance to IPC – based inspection

- Advanced angle-view inspection of hidden solder joints

- Developed with I4.0 in mind for advanced Machine to Machine communication

- Multi-lateral system monitoring and Predictive Maintenance for 100%, utilization for Production

- Global Library to maintain the same quality standard of manufacturing in all global sites

- High reliability OCR / OCV image detection

- Unique Single Hardware across all S10 Series Platform

- Prepared for the next-generation hardware, camera/GPU/PC for higher detectability/speed capability

- Since values conforming to the standards are directly applied as inspection criteria, there is no dependency on the skill and expertise of the programmer.

- 1. AI self-optimization

- 2. Automatically acquire defect images for analysis and visualization of result data separation for AI-assisted defect determination

- 3. Visualization of the AI-determined settings

- High-precision solder shape reconstruction

- Equipped with our unique MDMC (Multi Direction/Multi Color) illumination and new MPS (Micro Phase Patented Shift) moiré technique. This enables higher robust and reliable inspection performance.

- M2M*1 system focusing on quality

- 1. Preventing defects by:

- monitoring and reporting fluctuations in the measured values during production

- visualizing defect trends associated with chip mounter hardware such as heads and nozzles

- 2. Visualizing the quality by:

- process comparison

- displaying production status

- linking SPI/AOI/AXI systems

| Type | VT-S1080 | |

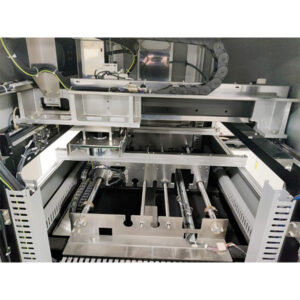

| Outer dimensions | 1180(W) x 1450(D) x 1500(H)mm | |

| Weight | Approx. 1250 kg | |

|

Power supply |

Voltage | 200 to 240 V AC (Single phase); Voltage fluctuation range ±10% |

| Rated power | 2.0 kVA (Maximum current 10 A) | |

| Line height | 900±20mm | |

| Air supply | Not required | |

| Operating temperature range |

10 to 35°C |

|

| Operating humidity range | 35 to 80% RH (Non-condensing) | |

|

Vision system |

Imaging system | 12M pixel camera |

| Inspection principle | MDMC*1 illumination + 3D reconstruction through MPS*2 technology | |

| Image resolution | 12.5µm | |

| FOV | 50.0 x 37.5mm | |

| Supported PCB size | 50(W) x 50(D)~510(W) x 680(D)mm | |

| Weight | (Max) 4 kg | |

| Thickness | 0.4~4mm | |

|

Clearance |

Above the conveyor belt: 54 mm or less; Below the conveyor belt: 50 mm or less

(Including board thickness/curvature/bend/part tolerance, etc.) |

|

| Height measurement range |

25mm |

|

Additional information

| Brand |

OMRON |

|---|

Reviews (0)

Be the first to review “VT-S1080 | OMRON Automation – PCB Inspection System” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.