PowerWave N2 | Automatic Soldering | Seho

PowerWave N2 | Automatic Soldering | Seho

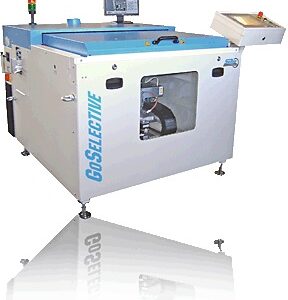

- The nitrogen wave soldering system SEHO PowerWave N2 is designed for medium to large-sized production volumes and particularly puts a focus on optimizing your production quality while minimizing the manufacturing costs

- The system is ideally suited for both, lead-containing and lead-free soldering processes.

- The modular construction of SEHO PowerWave offers the ideal concept for all production requirements and allows the machine to be integrated into existing fully automated lines.

PowerWave N2

PowerWave N2 | Automatic Soldering | Seho

The Powerful Systems for Medium to Large Production Volumes

While featuring comparatively low investment cost and minimum operating expenses, the system offers ideal value for money, thus ensuring high profitability. The system is ideally suited for both, lead-containing and lead-free soldering processes. Based on SEHO‘s leading nitrogen technology, demanding surface mount assemblies are as perfectly soldered as through-hole assemblies. This is accomplished with the innovative tunnel concept, individually in speed controllable conveyor segments, the reproducible flux application, the modular preheat configuration and the up-to-date soldering area which leaves nothing to be desired.

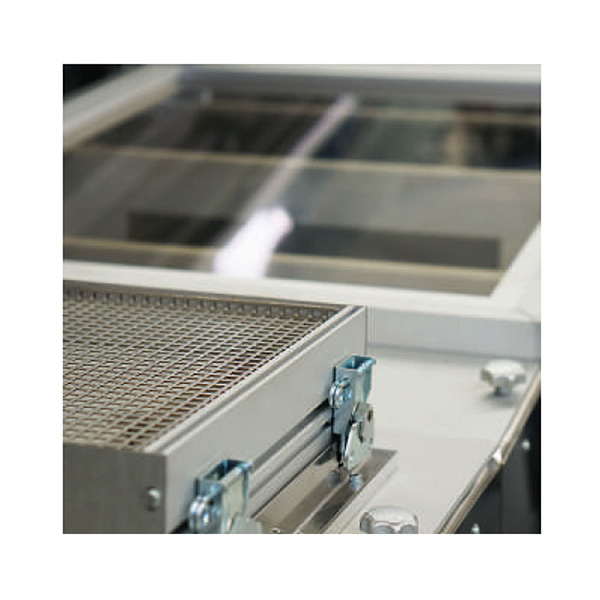

The machine is equipped with a closed tunnel system. The special design of the stainless steel tunnel guarantees a low nitrogen consumption. A very high energy efficiency is reached because of the lateral insulation.

The spray fluxer with HVLP technology ensures a stable spray jet and a very precise spray pattern, also at the outer edges. This features a reproducible fluxing process with a remarkably reduced flux consumption.The flexible preheating area with 1800 mm (70.88″) active length enables the system to be adapted to your specific production requirements.Up-to-date and innovative wave formers ensure maximum flexibilit

effective and energy efficient

The PowerWave N2 is equipped with a closed tunnel system. The special design of the stainless steel tunnel results in a low nitrogen consumption. A new and innovative tunnel insulation ensures very high energy efficiency – a clear advantage for your production costs. Hinged heat-resistant glass covers not only make for a very attractive design but also allow ideal accessibility to all

machine areas.

reproducible and sparing

The PowerWave N2 is provided with an innovative fluxer unit that reduces flux consumption remarkably, and simultaneously makes for low maintenance requirements. The fluxer is driven motorically, thus providing several advantages. Offset and spray width can individually be programmed, travel speed and positioning are absolutely accurate and reproducible.

The spray head with HVLP tecnology (high volume – low pressure) ensures a stable spray jet and a very precise spray pattern even at the outer edges of the printed circuit boards. Aflux quantity monitoring system ensures reliable processes and perfect results. This features a reproducible fluxing process with a considerably reduced flux consumption. Simultaneously, maintenance requirements are tremendously reduced as this system overall features less soiling of the fluxer area.

modular and productive

The flexible preheating zone configuration with an active length of 1800 mm [70.86″] enables the system to be adapted to your specific production needs.

Depending on the requirements, the PowerWave N2 may be equipped completely individual. IR preheat zones ensure an even heating of the entire assembly while quartz heaters make for a quick heat transfer and compensate temperature differences because of unequal mass proportion within the

assembly. Convection modules are particularly effective and component-sensitive. They guarantee a very homogeneous heating of the assemblies and they are ideally suited for processing of water-based fluxes as they perfectly evaporate the water content. In the case of high-mass printed circuit boards, top-side heating modules may be installed additionally. Of course, each preheat zone can be adjusted individually and is separately monitored and controlled.

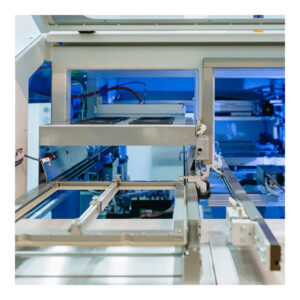

open for all challenges

The heart of the PowerWave N2 – the soldering area – offers a flexible configuration which leaves nothing to be desired. Innovative, up-to-date wave formers combined with an ideal nitrogen atmosphere ensure optimum soldering results. A programmable, automatic height adjustment of the solder

nozzles makes for highest flexibility. Of course, the PowerWave N2 also is ideally suited for processing of lead-free solder alloys. All machine parts

coming into contact with the liquid solder are protected with a special composit coating. The solder nozzles are prepared for lead-free processes with

a multilevel nitration treatment. The programmable sectorial soldering mode and many other innovative features bring the PowerWave N2 to perfection.

Specifications

- outstanding and compact machine design, technically equipped like the large systems

- flexible configuration, tailored to suit your production requirements

- ATS spray fluxer for a cost-saving and precise flux deposition

- variable and powerful preheat area with convection, infrared and quartz

- individually configurable soldering area – ideally suited for lead-free applications

- new and up-to-date single or dual solder nozzle technology for SMT and THT assemblies

- local nitrogen inertion of the solder waves

- up-to-date control unit with PC for easy and quick programming

- with flexible solder frame conveyor, or finger conveyor for direct processing of PCBs or solder masks

| Brand |

SEHO |

|---|