Home » Products » SMT Line Machine » SMT Cleaners Machines » PBT SuperSWASH

PBT SuperSWASH

SuperSwash | PBT – SMT Cleaning Machine

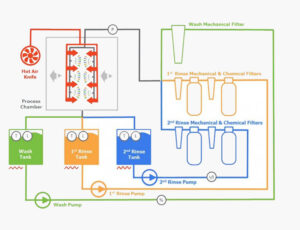

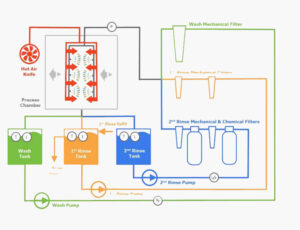

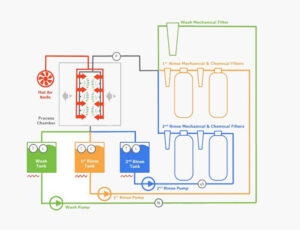

- Fully automatic high performance zero drain system

- Ideal for cleaning middle to high volume of electronic assemblies

- Suitable for cleaning high volume of stencils

Category: SMT Cleaners Machines

Tags: PBT, SMT Cleaners Machine, SuperSwash

Description

SuperSwash | PBT – SMT Cleaning Machine

SuperSwash

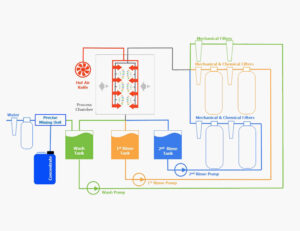

- Wash loop is always closed and fully filtrated process that requires regular dosing and periodic drainage when saturated.

- Various ways of processing of contaminated rinse loop water.

- Rinse loops in SuperSWASH are flexible by design and meet all process and environmental requirements.

- Defluxing, removing activators and resin residues

- Cleaning contamination from handling and board manufacturing

- Cleaning highly populated electronic assemblies with low standoff components such as BGA, CSP, LGA, MELF etc.

- Cleaning of power electronics

- Cleaning electronic assemblies requiring extra short process time

- Cleaning second side misprints on complex assemblies

- Cleaning before conformal coating

- Cleaning before wire bonding

- Low consumption of chemicals and water

- Outstanding options of water utilization

- Adaptive rinse water quality control

- Up to 3 fully separated liquid loops

- Automatic chemical concentration control

- Ultimate cleaning performance

- Easy operation

- Zero drain concept

- Linear direct spray for equal washing

- Hot air knife direct dry

- Illuminated glass door chamber for visual process control

- Quick changover to Twingo – double capacity configuration

- Wide range of standard and customized PCBA fixtures

- Clamping for all types of stencils

- Simple detailed programming

- Complete datalogging and bar code traceability

- Wide range of standard fixtures and adaptors for any types of PCBAs and electronic assemblies

- PBT Works can additionally custom design any special clamping fixture required

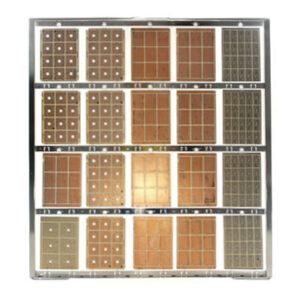

BASKETS FOR ANY PCBA

- Stainless wire baskets for quick and easy loading of PCBAs

- Available in various sizes

- Quick exchange of basket types – no tool needed

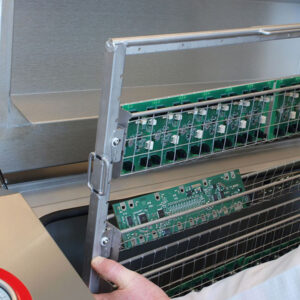

HORIZONTAL BARS WITH SPRINGS

- According to IPC 610, PCBAs shall be handled by the edges which are generally technologically missing

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped

- Bars are quickly and easily adjustable in vertical direction with no need of tool

SLIDE-IN FIXTURES FOR SINGLE FORMATS

- Vertical bars with plastic slide-in fixtures can speed up the loading process

- Easy and quick operation

- Precisely adjustable spacing in-between bars

- Plastic slide-in fixtures available in various dimensions

- Only available upon request

FIXTURES FOR CERAMICS

- Ceramic substrates can be secured on specially designed bars with wire springs for firm yet fine fixation

- Frame with fixed bar spacing offers gentle handling

- Available only upon request

- Top quality cleaning requires powerful and perfectly stable process

- SuperSWASH software provides very detailed programming

- Full range of data monitoring to assure high repeatability of results

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistence, concentration etc.)

- Process steps may contain up to 5 substeps for perfect setup

- Indication of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- All parameters and messages are saved on a simple log

- All process parameters can be easily viewed in graphs

- OS available in several different languages

- Automated digital concentration monitoring system ZESTRON® EYE enables precise measurement and control in real time

- Proper concentration of chemicals in wash loop necessary for stable and reliable cleaning process

- Data from ZESTRON® EYE are fully integrated in the machine software

- Designed for ZESTRON cleaning agents

- Process parameters can be set and viewed on the unit touchscreen

- Real-time automatic concentration monitoring and reporting with KYZEN ANALYST™

- Stable and reliable cleaning process strongly depends on proper concentration of chemicals in wash loop

- Advanced data analytics system designed for all chemistries

- Data from KYZEN ANALYST™ are fully integrated in the machine software

- Process parameters can be set and viewed on the unit touchscreen

- Applicable for absolute control of wash process

- Automatic system ensures stable concentration of cleaning agent

- The dosing unit refills the wash tank by pre-set concentration of the cleaning agent and DI water from external source or generated by the unit

- Adaptive concentration control and dosing unit utilizes integrated ZESTRON® EYE or KYZEN ANALYST™ monitoring

Additional information

| Brand |

PBT Works |

|---|

Reviews (0)

Be the first to review “PBT SuperSWASH” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.