Home » Products » SMT Line Machine » SMT Cleaners Machines » PBT MiniSWASH

PBT MiniSWASH

MiniSwash | PBT – SMT Cleaning Machine

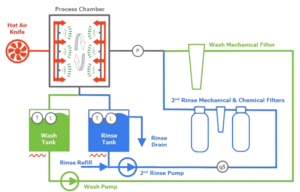

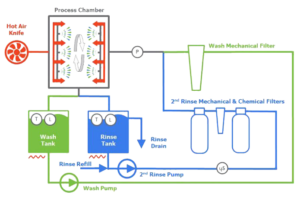

- Fully automatic zero drain system.

- Ideal for cleaning stencils, screens and misprints.

- Suitable for defluxing of small volume of PCBA with high quality requirements.

Category: SMT Cleaners Machines

Tags: MiniSwash, PBT, SMT Cleaners Machine

Description

MiniSwash SMT Cleaning Machine | PBT

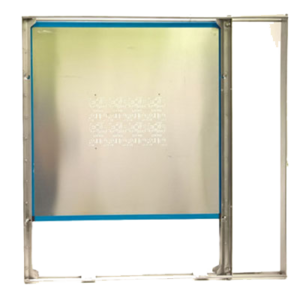

Miniswash

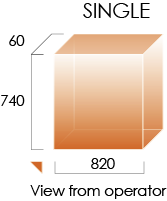

- Single frame configuration

- Closed loop zero drain system

- Rotary direct spray

- Hot air knife direct dry technology

- Anti-collision system

- Compatible with chemistry from various suppliers

- Small footprint

- Clamping for all types of stencils and squeegees

- Adjustable frame fixing system

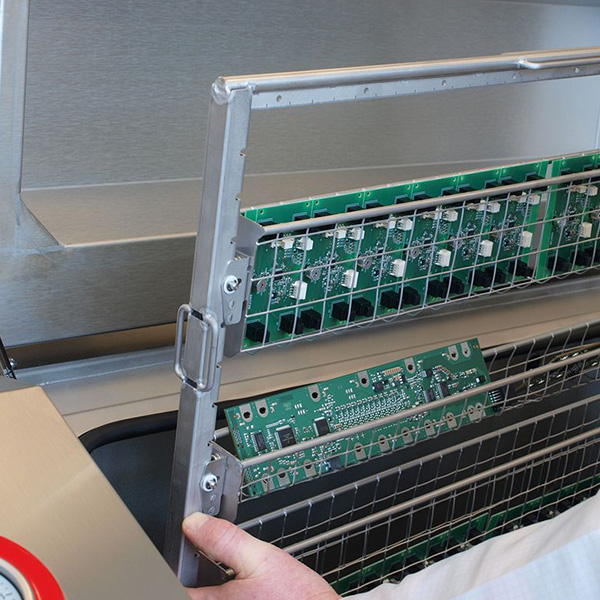

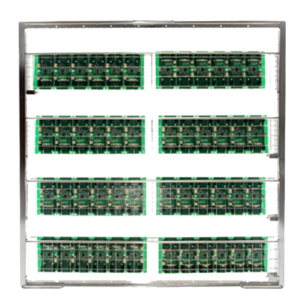

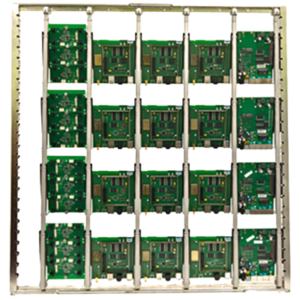

- Wide range of PCBA fixtures

- Two fully separated liquid loops

- Low consumption of chemicals and water

- Outstanding options of water utilization

- Intuitive touchscreen interface

- PLC control

- Barcode traceability, LAN connectivity

- Adaptive rinse process control

- Multi language selection

MiniSwash SMT Cleaning

- Removing solder paste from any type of stencils, screens and printer squeegees

- Removing SMT Glue residues from any type of stencils, screens or PumpPrint stencils

- Defluxing, removing activators and resin residues, cleaning contamination from handling and board manufacturing

- Cleaning second side misprints on complex assemblies

USABLE SPACE OF CHAMBER

- Developed to match modern cleaning agents.

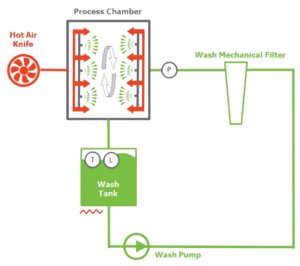

- Wash loop is closed and fully filtrated process.

- Filtration extends the bath life to lower the process costs.

- Various efficient ways of processing contaminated rinse loop water.

- Rinse loops are flexible by design to meet various process and environmental requirements.

- Conventional framed stencils and screens fit directly into the built-in adjustable clamping.

- Wide range of standard fixtures and adapters for any type of stencils and PCBAs.

- PBT Works can additionally custom design any special clamping fixture required.

- According to IPC 610 PCBAs shall be handled by the edges which are generally technologically missing.

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force.

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped.

- Bars are quickly and easily adjustable in vertical direction with no need of tool.

- Top quality cleaning requires powerful and perfectly stable process

- MiniSWASH software provides very detailed programming

- Full range of data monitoring to assure high repeatability of results

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistance)

- Indication of minimal level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- OS available in several different languages

Additional information

| Brand |

PBT Works |

|---|

Reviews (0)

Be the first to review “PBT MiniSWASH” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.