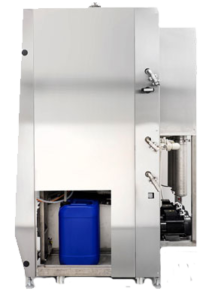

Home » Products » SMT Line Machine » SMT Cleaners Machines » PBT HyperSWASH Cleaning Machine

PBT HyperSWASH Cleaning Machine

HyperSWASH | PBT – SMT Cleaning Machine

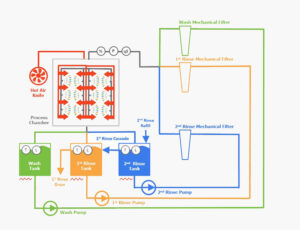

- Fully automatic cleaning machine

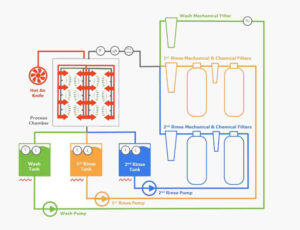

- Spray-in-air closed loop zero drain system

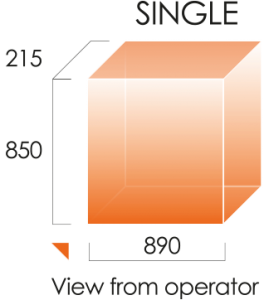

- Multiple platform configuration

- Superb for cleaning high volume of electronic assemblies

Category: SMT Cleaners Machines

Tags: HyperSWASH, PBT, SMT Cleaners Machine

Description

HyperSWASH PBT Cleaning Machine | SMT

HyperSWASH SMT Cleaners

- Exceptional concept of multiple configuration

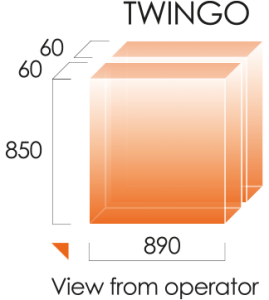

- TWINGO for the highest performance

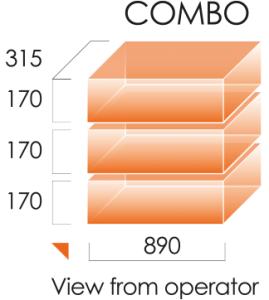

- COMBO for maximum cleaning capacity

- Closed Loop Zero Drain system

- Linear Direct Spray

- Linear Tangent Spray

- Effective Hot Air Knife Direct Dry

- Illuminated chamber

- Glass door panel for visual control

- 3 fully separated liquid loops

- 100% closed loop filtration

- Two self-sustaining rinse loops

- Advanced options of water utilization

- Adaptive rinse water quality control

- Various cleaning agent compatibility

- Low consumption of chemicals and water

- Standard and customized PCBA fixtures

- Touchscreen interface with Windows OS

- Multilanguage selection

- Statistical process control (SPC)

- Data logging and barcode traceability

- AAD Automatic adaptive dosing of cleaning agent

- Concentration sensor ZESTRON® EYE or KYZEN ANALYST™

- Developed to match modern cleaning agents

- Wash loop is closed and fully filtrated process

- Filtration extends the bath life to lower the process costs

- Various efficient ways of processing contaminated rinse loop water

- Rinse loops are flexible by design to meet various process and environmental requirements

- Wide range of standard fixtures and adaptors for any types of PCBAs

- PBT Works can additionally custom design any special clamping fixture required

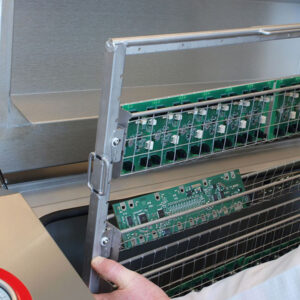

TWINGO DOUBLE FRAME HOLDER

- Configuration for the highest performance

- Stainless telescopic adapter to hold two frames

- Easy handling of frames outside the chamber

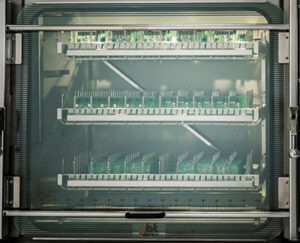

COMBO MULTI LEVEL BASKET

- Unique design for required number of baskets

- Stainless wire racks in each basket to accommodate high amount of electronic assemblies

- Best for high volume cleaning

- Quick and easy loading of PCBAs

- Customization available

BASKETS FOR ANY PCBA

- Stainless wire baskets for quick and easy loading of PCBAs

- Available in various sizes

- Quick exchange of basket types – no tool needed

HORIZONTAL BARS WITH SPRINGS

- According to IPC 610, PCBAs shall be handled by the edges which are generally technologically missing

- PBT Works developed special springs for fixing which can be positioned precisely along the horizontal bars to gain perfectly balanced grip force

- Spring bars allow to fix wide range of products from small and light to large and heavy, even unusually shaped

- Bars are quickly and easily adjustable in vertical direction with no need of tool

SLIDE-IN FIXTURES FOR SINGLE FORMATS

- Vertical bars with plastic slide-in fixtures can speed up the loading process

- Easy and quick operation

- Precisely adjustable spacing in-between bars

- Plastic slide-in fixtures available in various dimensions

- Only available upon request

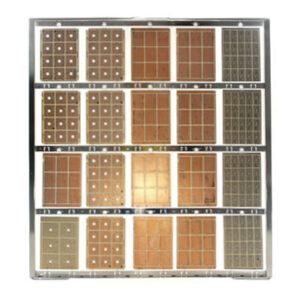

FIXTURES FOR CERAMICS

- Ceramic substrates can be secured on specially designed bars with wire springs for firm yet fine fixation

- Frame with fixed bar spacing offers gentle handling

- Available only upon request

- Top quality cleaning requires powerful and perfectly stable process

- HyperSWASH software provides very detailed programming

- Full range of data monitoring to assure high repeatability of results

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistence, concentration etc.)

- Process steps may contain up to 5 substeps for perfect setup

- Indication of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- All parameters and messages are saved on a simple log

- All process parameters can be easily viewed in graphs

- OS available in several different languages

- Applicable for absolute control of wash process

- Automatic system ensures stable concentration of cleaning agent

- AAD unit integrated inside the machine body

- Can be added to cleaning machine additionally

- The dosing unit refills the wash tank by pre-set concentration of the cleaning agent and DI water from external source or generated by the unit

- Adaptive concentration control and dosing unit utilizes integrated ZESTRON® EYE or KYZEN ANALYST™ monitoring

- Automated digital concentration monitoring system ZESTRON® EYE enables precise measurement and control in real time

- Proper concentration of chemicals in wash loop necessary for stable and reliable cleaning process

- Data from ZESTRON® EYE are fully integrated in the machine software

- Designed for ZESTRON cleaning agents

- Process parameters can be set and viewed on the unit touchscreen

- Real-time automatic concentration monitoring and reporting with KYZEN ANALYST™

- Stable and reliable cleaning process strongly depends on proper concentration of chemicals in wash loop

- Advanced data analytics system designed for all chemistries

- Data from KYZEN ANALYST™ are fully integrated in the machine software

- Process parameters can be set and viewed on the unit touchscreen

Reviews (0)

Be the first to review “PBT HyperSWASH Cleaning Machine” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.