Home » Products » SMT Line Machine » SMT Cleaners Machines » PBT CompaCLEAN

PBT CompaCLEAN

CompaClean | PBT Cleaning Machine

- Fully automatic zero drain system

- Ideal for cleaning middle to high volume of electronic assemblies

- Suitable also for cleaning of soldering pallets and mechanical parts

Category: SMT Cleaners Machines

Tags: CompaClean, PBT, SMT Cleaners Machine

Description

CompaClean | PBT Cleaning Machine

Compaclean

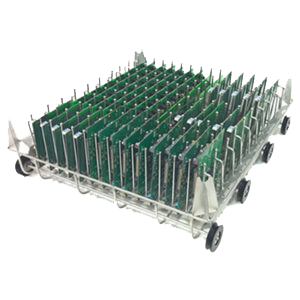

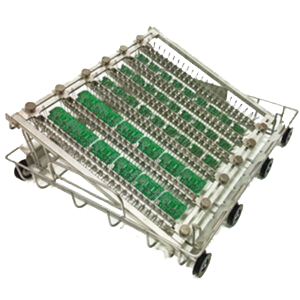

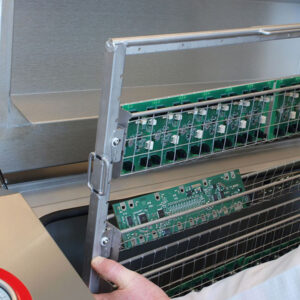

- Wide range of standard fixtures and adaptors for any type of PCBAs and soldering pallets

- PBT Works can additionally custom design any special clamping fixture required

- Regularly refills fresh DI water from external source to rinse tank

- Regularly drains used water from rinse tank

- Perfect for high volume maintenance cleaning

- Developed to match modern cleaning agents

- Wash loop is closed and fully filtrated process

- Filtration extends the bath life to lower the process costs

- Various efficient ways of processing contaminated rinse loop water

- Rinse loops are flexible by design to meet various process and environmental requirements

- Integrated chemical filters keep the machine footprint relatively small

- First rinse filtration fully separated from second rinse filtration

- Ideal for middle volume cleaning and zero drain requirements

- External closed loop high capacity chemical filters

- First rinse filtration fully separated from second rinse filtration

- Ideal for middle volume cleaning and zero drain requirements

Compaclean | SMT Cleaners – PBT

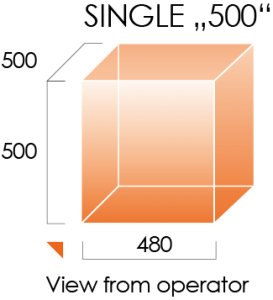

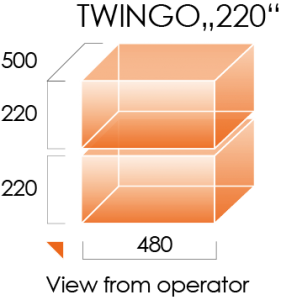

- SINGLE or DOUBLE capacity racks

- High volume batch size

- Closed loop zero drain system

- Uniform spray coverage with high stroke oscillating rack

- Fixed nozzle system

- Powerful hot air dryer

- Cascade filtration

- Compatible with wide range of chemistry

- Small footprint

- 100% closed loop filtration

- Double rinse option

- Glass door panel for visual control

- Wide range of standard and customized PCBA fixtures

- Up to 3 fully separated liquid loops

- Outstanding options of water utilization

- Touchscreen interface with Windows OS

- Simple programming

- Complete data logging and optional bar code traceability

- Week program with automatic start

- Multi language selection

- AAD Automatic adaptive dosing of cleaning agent

- Concentration sensor ZESTRON® EYE or KYZEN ANALYST™

Compaclean

- Defluxing, removing activators and resin residues

- Cleaning contamination from handling and board manufacturing

- Cleaning second side misprints on complex assemblies

- Cleaning before conformal coating

- Cleaning of soldering pallets

- Fine degreasing of mechanical parts

- Top quality cleaning requires powerful and perfectly stable process

- SuperSWASH software provides very detailed programming

- Full range of data monitoring to assure high repeatability of results

- Optional glass door allows for visual control

- Illuminated machine chamber

- Cleaning process can be directly monitored and quickly optimized either for speed or for best results

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters (time, temperature, pressure, conductivity-resistence, concentration etc.)

- Process steps may contain up to 5 substeps for perfect setup

- Indication of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Process messages, warnings and errors are clearly displayed

- All parameters and messages are saved on a simple log

- All process parameters can be easily viewed in graphs

- OS available in several different languages

- Automated digital concentration monitoring system ZESTRON® EYE enables precise measurement and control in real time

- Proper concentration of chemicals in wash loop necessary for stable and reliable cleaning process

- Data from ZESTRON® EYE are fully integrated in the machine software

- Designed for ZESTRON cleaning agents

- Process parameters can be set and viewed on the unit touchscreen

Additional information

| Brand |

PBT Works |

|---|

Reviews (0)

Be the first to review “PBT CompaCLEAN” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.