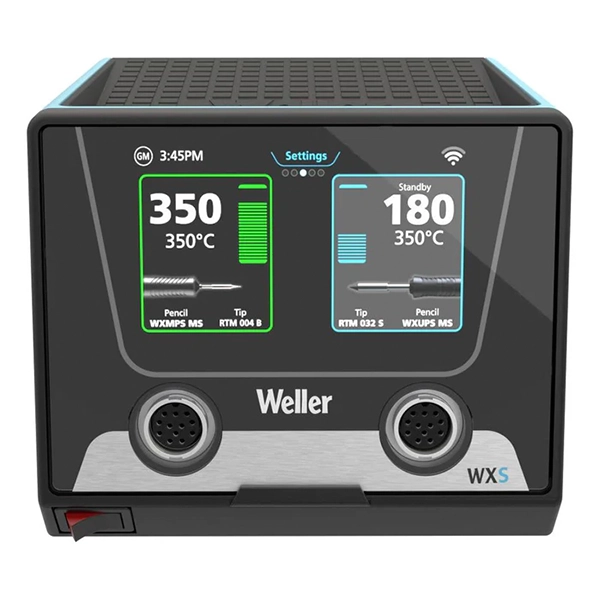

Weller WX Smart | Soldering Station

WXsmart Soldering Station | Control Unit

- Full Traceability of the Soldering Process.

- All Connectivity Interfaces Embedded.

- Industrial and Factory-Ready.

- High Power & Fast Heat-Up.

- Multi-Tool Compatibility.

- Smart Touch Display.

Weller WXsmart Soldering Station

The all-in-one WXsmart hand soldering platform offers maximum traceability and connectivity. As the most connected, controlled and secured hand soldering solution in the world, WXsmart is connecting the future of soldering.

Weller WX Smart | Soldering Station

- Full Traceability of the Soldering Process.

- All Connectivity Interfaces Embedded.

- Industrial and Factory-Ready.

- High Power & Fast Heat-Up.

- Multi-Tool Compatibility.

- Smart Touch Display.

Download Datasheet

Download DatasheetWXMP MS Active Tip Heating Technology 40W, 12V

- Micro soldering pencil with 40 W, 12 V for WX stations

- Safety rest WDH 51

-

Extremely short heating time

Download Datasheet

Download DatasheetWXsmart Soldering Station | Weller

Maximum connectivity, supporting IoT standards for full traceability with mobile-enabled, easy remote control access

The all-in-one station acts as the brain of the workbench by consolidating all soldering applications into one station

Total Process Control (TPC) to manage your complete soldering process from tip to station

The first system with built-in cyber-security to prevent costly downtimes

The All-In-One Soldering Station for Every Soldering Task and Challenge:

The first hand soldering station that provides maximum connectivity, with all interfaces embedded (ex: factory), with no need for any additional hardware costs.

All Connectivity Interfaces Embedded:

The first hand soldering station that provides maximum connectivity, with all interfaces embedded (ex: factory), with no need for any additional hardware costs.

Full Traceability of Soldering Process:

Tracing the hand soldering process with the WXsmart platform provides complete transparency, full process documentation and high process control. This greatly reduces failure in the soldering production, providing a higher quality of end result products and output.

Full traceability

Easy, fast and flexible integration into every It-environment, with or without cable. First system with all interfaces embedded ex factory, no additional costs. Choose your preferred connection.

- WiFi

- LAN

- USB

- RS 232

Highest productivity

Using existing IoT standards, we can deliver data that can be integrated in your ERP system. Easy and flexible data availability in different data formats. Data handling and memory from manual hand soldering in real time.

- Industry 4.0 ready

- Integration in existing systems for protocols

Less cost risks

Weller App for real-time data dashboards and for simple remote control. High flexibility when reading and uploading data (hardware, protocols, communication of systems and process information)

- PC / Monitor

- Smartphone

- Tablet

- Control screens in production area

intuitive WXsmart App for Total Process Control

Download the app on google play or app store and control your soldering process for multiple stations from one device like tablet or mobile phone fast and easy. This provides full conrol of the soldering process identifies wrong settings and failures easily.

- Transparent solder process

- Increasing productivity

- Higher Quality

- Saves time and total cost of ownership

Auto calibration

Weller’s WCU is a compact stand-alone high-precision temperature measurement device for quick and accurate temperature measurement.

Modularity

Backwards compatibility of tips and tools for soldering, desoldering and hot-air applications, ensures the security of your all-in-one station investment.

The All-In-One Soldering Station for Every Soldering Task and Challenge

The first hand soldering station that provides maximum connectivity, with all interfaces embedded (ex: factory), with no need for any additional hardware costs.

All Connectivity Interfaces Embedded:

The first hand soldering station that provides maximum connectivity, with all interfaces embedded (ex: factory), with no need for any additional hardware costs.

Full Traceability of Soldering Process:

Tracing the hand soldering process with the WXsmart platform provides complete transparency, full process documentation and high process control. This greatly reduces failure in the soldering production, providing a higher quality of end result products and output.

| Dimensions L x W x H | 6.90 x 6.06 x 5.70 in 175 x 154 x 144 mm |

| ESD Safe | Yes |

| Fuse | 230 V / T3,15A |

| Power | 300 W |

| Temperature Accuracy °C | ± 9°C |

| Temperature Accuracy °F | ± 17°F |

| Temperature Range °C | 100 – 450 (550) °C |

| Temperature Range °F | 200 – 850 (950) °F |

| Traceability | Yes |

| UPC | 4003019444588 |

| Voltage | 230 V |

| Product Family | WXS Line Soldering |

| Brand | Weller |

|---|

You must be logged in to post a review.

Related products

Reviews

There are no reviews yet.