Go29 Printer PBT

Go29 Printer PBT

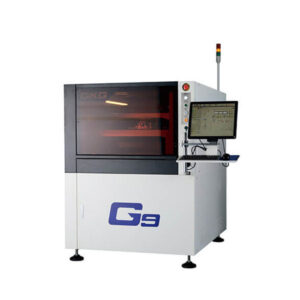

- PBT Go29 Printer Semi-automatic programmable highly precise and flexible off line 29” stencil

- PBT Go29 Printer Suitable for SMT production with camera guided alignment

Go29 Printer PBT Semi Automatic

Go29 Printer PBT

Go29 PBT

PBT Go29 Printer Perfect for rapid prototyping and small series production up to 29″ frame size. Brings excellent accuracy and complex functionality in a small benchtop footprint.

Solder paste printing is the most important process in SMT. Go Printers bring on highly precise print. PBT Go29 Printer Designed for accurate and repeatable printing. For any electronic application while maintaining low investment costs.

- Compact size and small footprint

- Quick PCB changes

- Smart design

- Fast product changeover

- Camera guided stencil to pad alignment

- X, Y, Theta playless table adjustment

- Power assisted upper frame opening

- Adjustable stencil clamping with pneumatic fixation

- Three position squeegee height control for quick stencil changes

- Patent pending no-tool squeegee changes

- Complete set of magnetic PCB fixturing

- Support bars adjustable to PCBA thickness

- Object space up to component height 23,5 mm

- Adjustable printing pressure

- Programmable board from stencil separation distance and speed

- Robust synchronized table separation motion

- Programmable print speed and squeegee range

- Small series production

- Prototyping and new product development

- Printing solder paste

- Printing SMD glue

- Printing thermoconductive paste

- Screenprinting of inks

- Thick film printing, printed electronics screenprint

- Print on ceramics, foils, metals

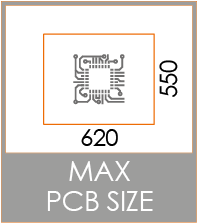

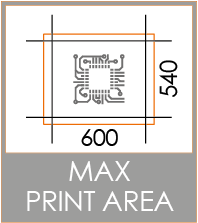

- Print area 600×540 mm

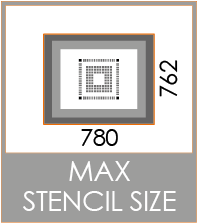

- Frame capacity 780×762 mm

- Compact size and small footprint

- Quick PCB changes

- Fast product changeover

- Camera guided through stencil alignment

- Playless precise alignment

- X, Y, Theta adjustment

- Power assisted upper frame opening

- Rubber based vacuum table

- Adjustable stencil clamping

- Adjustable printing pressure

- Programmable board from stencil separation distance and speed

- Robust synchronized table separation motion

- Programmable print speed and squeegee range

- Solder paste printing is the most important process in SMT

- Go Printers bring on highly precise print

- PBT Go29 Printer Designed for accurate and repeatable printing

- For any electronic application while maintaining low investment costs

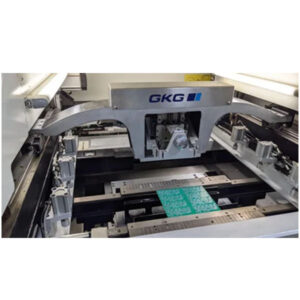

CAMERA CONTROLLED STENCIL TO PAD ALIGNMENT

- Dual LCD display mounted on the top of the upper frame provides a view of the solder pads on the PCB

- LED illuminates the target area for a crystal clear view through the stencil apertures

- A laser source attached to each camera speeds up navigation and camera positioning during setup

- This feature is especially helpful when locating specific stencil apertures to be used as alignment targets on densely populated electronic assemblies

- Solder paste printing is the most important process in SMT

- Go Printers bring on highly precise print

- Designed for accurate and repeatable printing

- For any electronic application while maintaining low investment costs

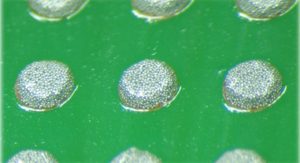

ROBUST SYNCHRONIZED TABLE SEPARATION

- Slow motion results in perfect shape

- Programmable separation speed matches thixotropy of any solder paste

- Robust design minimizes stencil vibration

- Pure mechanical synchronization for strictly parallel motion of the table

- Outstanding print quality, edge definition, and homogeneous solder paste distribution

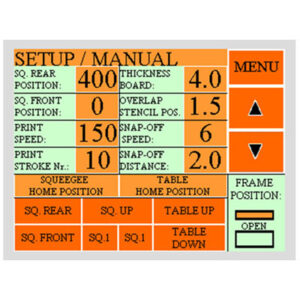

PROCESS CONTROL FEATURES

PBT Go29 Printer Full range of adjustable parameters assure repeatibility of results

Go series provides a level of touchscreen programmability and parameter control uncommon in benchtop SMT stencil printers

- PLC controller allows password-protected programming

- Wide range of parameter settings can be stored as files for various applications

- Programmable settings include print speed, print head front and rear stroke positions, snap-off speed, snap-off distance, PCB thickness, and a correction factor that compensates for stretch as the stencil begins to wear

- The software includes both an automatic mode and a manual/setup mode

- Step-by-step control of each segment of a print cycle, as well as a counter that keeps track of processed boards

- Storage and retrieval of up to 100 programs

FLEXIBILITY

Go printers come complete with a full supply of magnetic PCB mounting hardware

Wide range of squeegees available

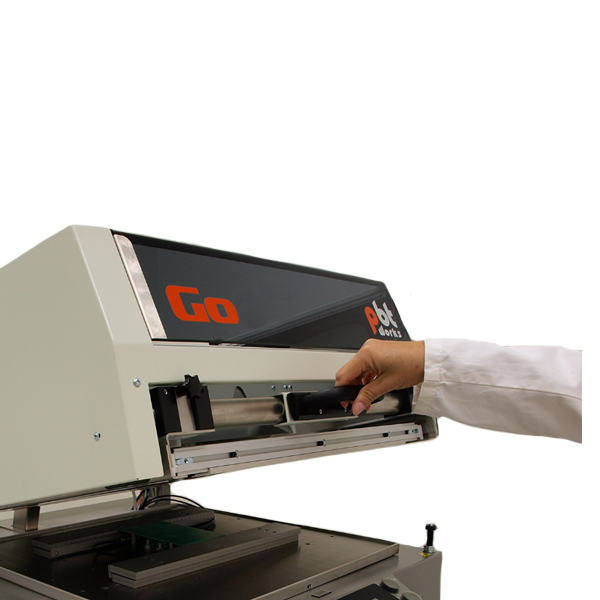

Quick and simple frame size adjustment and wide angle opening

Go printers come complete with a full supply of magnetic PCB mounting hardware

Well stepped range of squeegees available

Quick and simple frame size adjustment and wide angle opening

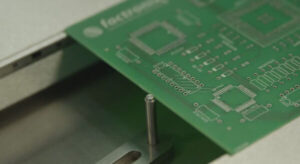

- Stencil frame slide-in clamping can be easily adjusted to fit frames of various sizes

- Stencil frames of thickness from 18 mm to 33 mm or 40 mm (Go29) are simply slid into the slides once the width is set

- With frame in place, a simple flip of a switch on the front of the unit activates four pneumatic clamping cylinders that lock the frame securely in place

- Unique design of the Go print head allows fast stencil changes without removing its dual squeegees

- Production mode of the squeegees is either in the Up position or the Down position within the frame envelope

- Up position is designed to keep the solder paste consistent and ready for repeated or next print

- Easy opening with pneumatic servo system, stops at any angle

- Independent of the frame weight or squeegee head position, upper frame can be lifted with minimal effort

- Two separate positions available – a partially opened position for maximum productivity that allows fast removal and loading of PCBs, and a wide 60° open position for board holder setup, cleaning, and maintenance

- Safety valves lock the upper frame position

| Brand |

PBT Works |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.