AX7900 – X-Ray Inspection Machine , SMT

AX7900 – X-Ray Inspection Machine , SMT

AX7900 X-Ray

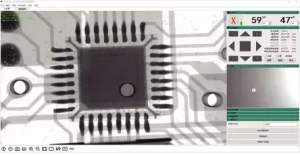

- onvenient target point positioning system.

- Multi-function DXI image processing system with XY programming for multiple image inspection routines.

AX7900 – X-Ray Inspection Machine , SMT

AX7900 X-Ray

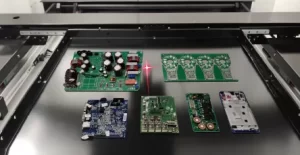

- X ray testing equipment pcb x-ray machine system have enabled fabricators of multi-layer PCBs to enhance product quality and control cost.

- The detection of high-definition video make you find out the joints open, short, voids and other defects at a glance.

- X-ray inspection enables users to control cost by eliminating defective board early in the production process.

Widely applied for BGA , CSP , Flip Chip, LED , Fuse,Diode, PCB, Semiconductor, Battery Industry, Small Metal Casting, Electronic Connector Module, Cables, Photovoltaic Industry, etc.

AX7900 X-Ray

- 90KV 5μm X-ray tube, FPD Detector.

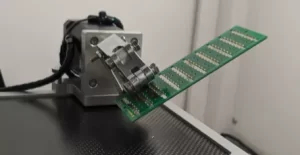

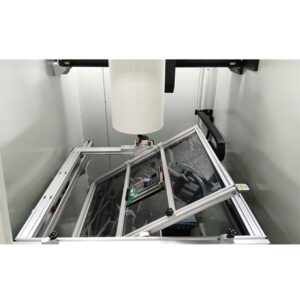

- Multi-function workstation, X-Y multi-axis movement. ±60° “Arc” motion(Option).

- Motion controls include: X/Y table motion plus Z axis tube and detector movement, ±60° tilt motion (option).

- Multi-function DXI image processing system.

- X/Y programming function for multiple image inspection routines

- Max. loading area 420mm x 420mm, max. detection area 380 x 380mm, with ~300X System Magnification.

- BGA void/area auto-measurement plus report generation.

|

X-Ray Tube |

||

| Max. Power: 8W

Focus Spot Size: 5μm |

Tube Type: Sealed

Voltage: 0~90kV(Adjustable) |

|

|

Imaging System |

||

| Pixel Size: 85μm

Frame Rates: 40fps System Magnification: 600X |

Detector: Flat Panel Detector (FPD)

Effective Detection AreaPixel Matrix : 65*65mm 768*768 |

|

|

Software |

||

| Auto-measuring Multiple Measuring Tools CNC Mode

Real-time Display Navigation |

BGA Soldering Voids Auto-measuring and Support Data/Graphic Output Support Measuring Distance, Angle, Diameter, Polygon, PTH filling rate, etc. CNC Programmable Inspection, Easy Operation and User Friendly

Real-time Displaying the Working Data of Voltage, Current, Angle, Date, etc Convenient Target Point Positioning System |

|

| Industrial PC | Motion Control System | |

| Monitor: 24’’ FHD LCD Display

System OS: Windows 10 64bit Hard disk: 1TB RAM: 8GB CPU model: Intel i7 Processor |

Movement Control: Joystick, Keypad & Mouse

Max. Loading Area/Weight: 520*420mm / 5kg Max. Inspection Area: 460*400mm Tilting Angle: ±360° Manipulator: 5- axis with X / Y / Z1 / Z2 / T |

|

|

Other Features |

||

| Energy Saving

Authority Management |

X-Ray Auto-off when it’s out of work over than 5 minutes

Fingerprint Access Management System, and Support Password Accessing. |

|

| X-Ray Safety

Safety Operation |

<1μSv/h (Meets All International Standards)

Electromagnetic Interlock, Warning Light and Real-time Radioation Leakage Monitor |

|

| Brand |

Unicomp |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.