Home » Products » SMT Line Machine » Printers » GKG-G5 | Full Automatic – Solder Paste Screen Printer

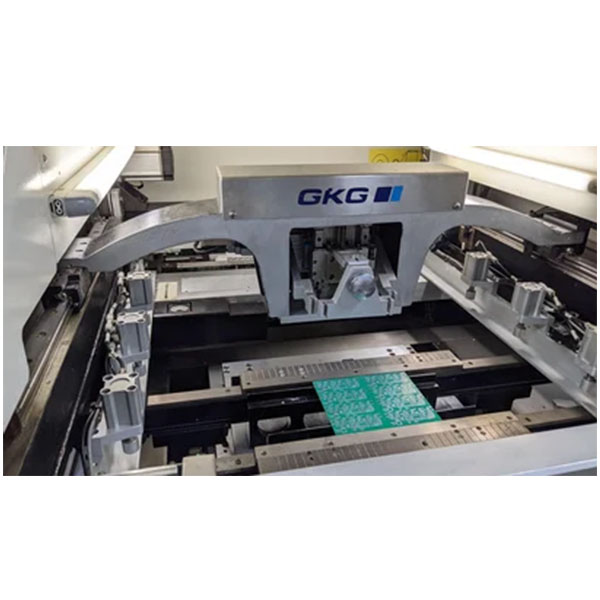

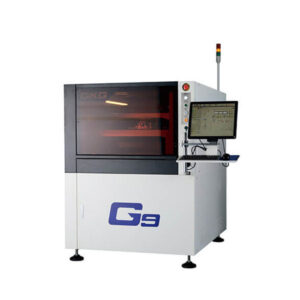

GKG-G5 | Full Automatic – Solder Paste Screen Printer

GKG-G5 | Full Automatic – Solder Paste Screen Printer

- GKG-G5 is high accuracy and high stability of the fully automatic printing machine vision,GKG followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution

Description

GKG-G5 | Full Automatic – Solder Paste Screen Printer

GKG-G5 SMT Solder Paste

GKG G5 Automatic SMT Stencil Printer:

- Cycle Time <8s

- PCB size:400mm x 340mm

- Weight:1000Kg

- size: 1140x1364x1404mm

- Product description: GKG G5 Automatic SMT Stencil Printer, Cycle Time <8s, PCB size:400mm x 340mm, size: 1140x1364x1404mm, Weight:1000Kg

- GKG Series High Precision Automatic Solder Paste Printer designed for high precision.

- steel mesh printing or stencil printing in SMT industry.

- Printing PCB size:50mm x 50mm ~400x340mm.

- PCB thickness: 0.4mm ~ 6mm.

- FPC thickness: ≦0.6mm (Excluding jig).

- Applicable pitches of Components.

- SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications.

- IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging.

- min. ball 0.2mm.

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics. medical power equipment, aerospace and aviation, besides general electronics products.

- 1)All new 3rd generation stencil X beam structure, add solder paste operators more convenient and accurate placement steel net.

- New type torque X beam, solve the solder paste and dust deposition, prolong the service life of the machine.

- 2)Scalable on pressure device, in view of easy deformation of the PCB printing can make the tablet out, don’t need to use pressure

- for a little while can back again. According to the product flexible use.

- 3)The whole machine use imported self-lubricating guide rail, guide rail need not add lubricant, within five years guide free maintenance within five years.

- 4)X Y1 Y2 in U.S. HAYDON linear motor, the Japanese precision drive screw, self-lubricating guide rail, to ensure accuracy.

- 5)Net frame Y to automatically locate, can quickly realize automatic stencil counterpoint.

- 6)Curved blade beam using high strength steel, in the printing process to ensure the stability of the print head.

GKG-G5 Technical Data

| Item | Parameter | |

| Repeat Position Accuracy | ±0.01mm(Test data and method are available) | |

| Printing Accuracy | ±0.025mm(Test data and method are available) | |

| Printing Speed / Cycle Time | <8s (Exclude Printing & Cleaning) | |

| Products Changeover | <5Min | |

| Screen Stencil Size/Min-Max | 737x737mm | |

| Screen Stencil Size/Thickness | 20mm ~ 40mm | |

| PCB Size/Min-Max/Thickness5 | 0X50mm-400x340mm/0.4~6mm | |

| PCB Warpage Ratio | <1%(Based on diagonal length) | |

| Bottom of Board Size | 15mm(Standard configuration), 25mm | |

| Edge of Board Size | 3mm | |

| Conveyor Height | 900±40mm | |

| Conveyor Direction | Left-Right; Right-Left; Left-Left; Right-Right | |

| Conveyor Speed | 100-1500mm/sec Programmable control | |

| Board Positioning | Support System | Magnetic pin/Side support block/Flexible automatic pin(optional) |

| Clamping System | Elastic side clamping/Vacuum nozzle/Extension-type Z-direction table setting | |

| Print head | Two indepandent Motorised printheads | |

| Squeegee Speed | 6~300mm/sec | |

| Squeegee Pressure | 0-10kg software control(closed-loop pressure feedback), pressure value visible | |

| Squeegee Angle | 60°(Standard )/55°/45° | |

| Squeegee Type | Steel squeegee (standard), rubber squeegee, and other types of squeegee shall be customized. | |

| Steel Mesh Separation Speed | 0.1~20mm/sec Programmable Control | |

| Cleaning Method | Dry-type, wet-type, vacuum-type ( Programmable combination of Cleaning methods) | |

| Table Adjustment Range | X:±3mm; Y:±7mm θ:±2° | |

| Type of Fiducial Point | Standard geometry shape of fiducial point, bonding pad / Stencil hole | |

| Camera System | Single digital camera for upward/downward vision system | |

| Air Pressure | 4~6Kg/cm2 | |

| Air Consumption | Approx 0.07m3 /min | |

| Control Method | PC Control | |

| Power Supply | AC:220±10%,50/60HZ 1Φ 1.5KW | |

| Machine Dimensions/Weight | Depends on exactly model | |

| Operation Temperature | -20°C ~ +45°C | |

| Operation Humidity | 30%~60% | |

Additional information

| Brand |

GKG |

|---|

Reviews (0)

Be the first to review “GKG-G5 | Full Automatic – Solder Paste Screen Printer” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.