JUKI RS-2 Pick and Place Machine | Fast Smart Modular Mounter

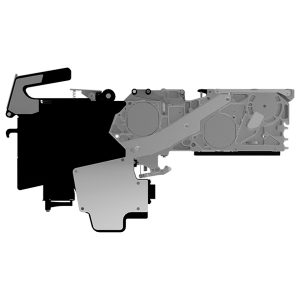

JUKI RS-2 – SMT | Fast Smart Modular Mounter

- JUKI’s proud laser recognition technology achieves high-speed and high-precision recognition.

- Takumi HEAD, which can detect variable sensor height.

- High-speed intelligent modular placement machine.

- 50,000CPH high speed.

JUKI RS-2 – SMT Pick and Place Machine

Features – JUKI RS-2 SMT Pick and Place Machie

50,000CPH high speed

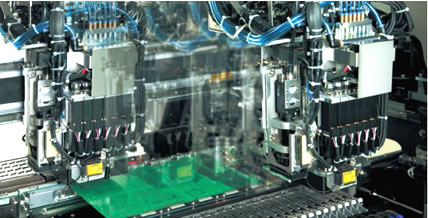

By positioning the laser sensor closer to the board and reducing travel time from pick-up to placement, the one-head mounter achieves an optimal speed of 50,000 CPH in its ideal conditions.

*Optimum condition

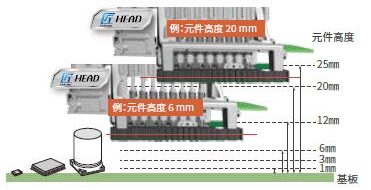

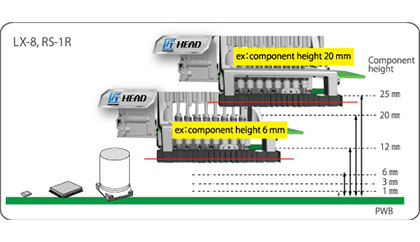

“TAKUMI Head” with adaptive sensor height JUKI RS-2 - SMT

The height of the laser sensor on the “TAKUMI Head” automatically adjusts based on the height of each component being placed,

allowing precise pick-up and placement.

This 8-nozzle “TAKUMI Head” accommodates components of varying heights, from the smallest to the largest, ensuring optimal

speed and accuracy.

Component height can be selected from six levels: 1, 3, 6, 12, 20, and 25 mm.

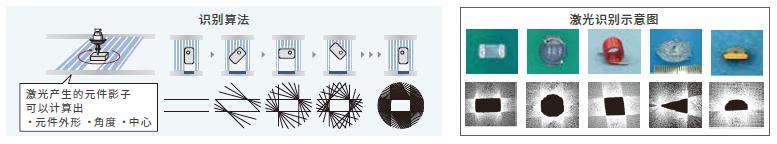

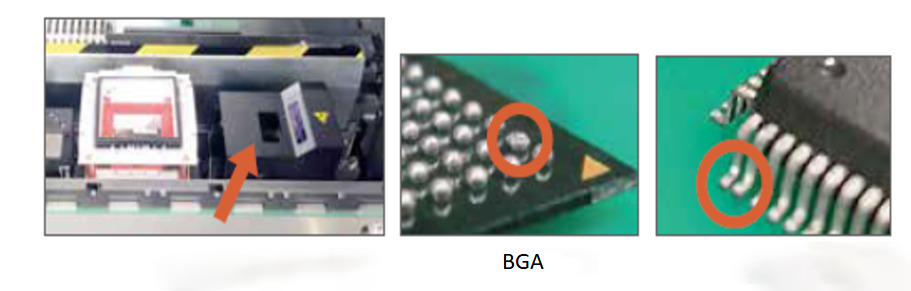

Realizes high-speed, high-precision recognition with JUKI’s proud laser-recognition technique

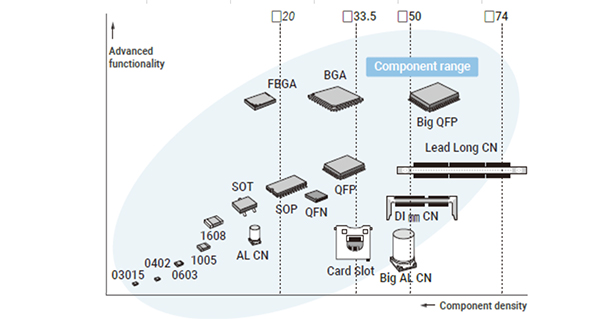

- JUKI’s laser-recognition technology enables fast, accurate identification of various component shapes, including BGA, SOP, and QFP, ranging from as small as 03015 to sizes up to 50 mm square.

- This laser-recognition system ensures stable recognition and placement, unaffected by variations in electrode shape or surface gloss.

- Additionally, creating component data is simplified, allowing for quick integration of new components.

Wide component range JUKI RS-2 - SMT

Supports components from sizes as small as 03015 up to 74 mm square or 50 mm x 150 mm, with placement heights accommodating components up to 25 mm.

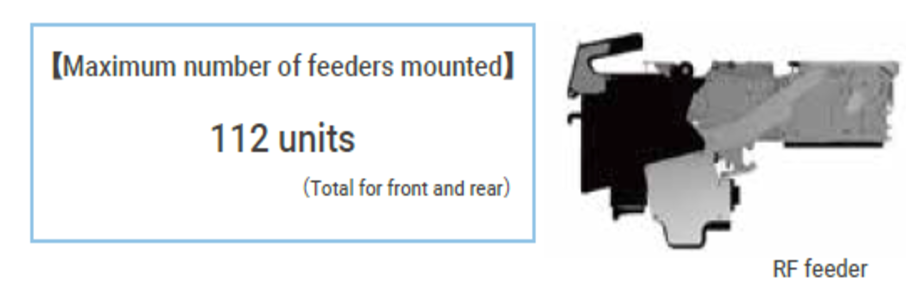

Up to 112 feeder mounting for flexible and efficient production

The compact, lightweight, and slim design of the RF feeder supports up to 112 feeder units (front and rear combined), enabling high-efficiency production. This setup is ideal for multi-product, small-lot production with minimized setup times.

* When RF feeder (RF08AS) is used.

Advanced high-precision coplanarity new model

Detects lead floating and BGA ball deformation to prevent the placement of defective components. High-precision coplanarity checks enhance product reliability.

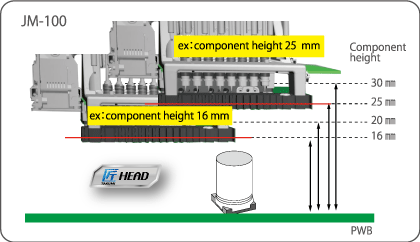

Automatic height change of recognition sensor

The 8-nozzle “Takumi head” automatically changes the laser sensor height according to the height of component that to be centered.

Various components from ultra-small component to large component can be optimally placed with best tact time.

LX-8, RS-1R: 6 levels (1, 3, 6, 12, 20, 25 mm) can be selected arbitrarily.

JM-100: 4 levels (16, 20, 25, 30 mm) can be selected arbitrarily.

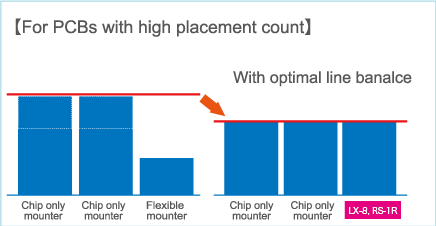

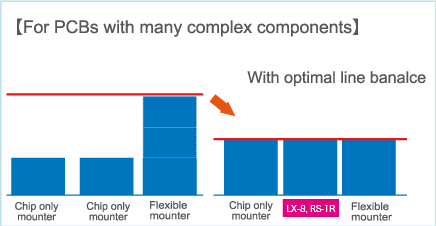

Optimum line balance and highest throughput

Changing the RS-1 functionality does not require head replacement. The revolutionary design self-optimizes based on the production requirements. The RS-1R can reduce the workload on high speed. A line with two or more RS-1Rs can adjust to a wide variety of production requirements from high speed to high flexibility.

Electric Double Tape Feeder EF08HDR

EF08HSR

- Electric Tape Feeders and mechanical feeders can be switched by the batch exchange trolley

When batch exchange trollies are set to four feeder banks, the mounter automatically recognizes whether electrical feeders or mechanical feeders are set.

- Effective utilization of assets

Existing mechanical feeders and batch exchange trollies can be used without any change.

Excellent setup workability JUKI RS-2 - SMT

The feed pitch can be switched with one touch to improve the efficiency of the setup change operation.

Visualization of operational status JUKI RS-2 - SMT

You can recognize the operating feeder and the feeder position at a glance thanks to LED indicators. If an error occurs, the corresponding LED indicator flashes to show you which feeder should be checked.

Component pick-up position correcting function

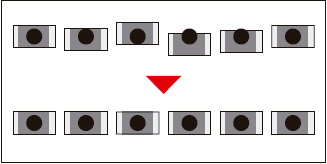

After a component is recognized, the position error information of a nozzle is reflecetd to a feeder. This feature allows you to automatically control the feeder so that components can be picked up at the same time stably.

Operability JUKI RS-2 - SMT

- Work to switch tape feeding pitch has been simplified. Status indication by LED increases efficiency of setup.

- Function to adjust feeder pick up position

Pickup misalignment as a result of part centering is sent to the feeder for automatic control of simultaneous pickup at stable pickup positions.

Stable supply JUKI RS-2 - SMT

By suppressing vibration, parts positions can be stabilized, realizing smooth and rapid supply of super small components.

JUKI’s original technology supports the high accuracy and high repeatability required for high density placement.

High-speed, on-the-fly centering

A high resolution laser is mounted on the head to center components in all directions including angle. Centering is done on-the-fly, allowing high speed placement of components from small chips to SOPs.

Adaptable centering

Centering accommodates component variations

Laser centering measures the components on the side. It is not affected by variations of component color or width/length so, unlike vision centering, there is no need to edit component data for different component vendors.

Component check function improves placement reliability

Since the laser is mounted on the head, it can be used to monitor the presence of components the entire time from pick to placement. This is difficult to accomplish with vacuum detection only. The placement reliability is also improved because the release of the component is confirmed after placement.

Features of the Vision Centering

- JUKI’s unique component centering systems.

- Dual centering methods (Laser or Vision)

Vision centering technology

method can be selected based on component type, shape, size and material. Laser centering is used for high speed placement of smaller components. Vision is used when lead or ball inspection is needed or when the component is too large for the laser. Many nozzles are available for odd-shaped components providing unsurpassed component handling.

General Vision

General vision function is used to support a wide variety of today’s unusual vision centered components. After programming is complete, the data can be verified by picking and test centering a component.

| Fast Smart Modular Mounter RS-2 | |||

| Board size | Minimum | 50 mm ×50 mm | |

| Maximum | 1 buffer | 800 mm ×370 mm | |

| 3 buffers | 410 mm×370mm | ||

| Allowable board weight | Max. 3 kg | ||

| Substrate thickness | 0.3~6.0mm | ||

| Component height | 25 mm | ||

| Component size | 03015-50 mm x 150 mm (1 x 3 segment recognition) x □74mm (2 x 2 segment recognition) | ||

| Placement speed | Optimum | 50,000CPH | |

| IPC9850 | 32,000CPH | ||

| Placement accuracy | ±35μm(Cpk≧1) | ||

| Feeder inputs | 112 products*1 | ||

| Power supply | Three-phase AC200V (Standard Type)/Three-phase 200 VAC to 415V (When the Type with Transformer is Selected) | ||

| Apparent power | 2.2 kVA | ||

| Operating air pressure | 0.5±0.05 MPa | ||

| Air consumption | When using a vacuum generator: 200L/min (standard), when using a vacuum pump: 50L/min (optional) | ||

| Machine dimensions (WxDxH)*2 | 1,500 mm ×1,686 mm ×1,450 mm | ||

| Mass(approximately) | 1,630kg | ||

| Brand |

JUKI |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.