VT-X750 OMRON | Automated X-RAY – Inspection System (AXI)

VT-X750 OMRON | Automated X-RAY – Inspection System

- VT-X750 is designed with the philosophy to achieve Zero Defect process lines.

- Traditional X-ray technologies are limited to inspect components like BGAs, LGAs or THT.

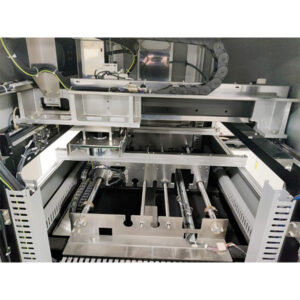

- VT-X750’s design overcomes these traditional shortfalls by incorporating high speed ‘Computed Tomography’ (CT), providing high-precision X-ray imaging to perform precise and reliable inspection of those hidden soldered areas during production.

VT-X750 OMRON | Automated X-RAY – Inspection System

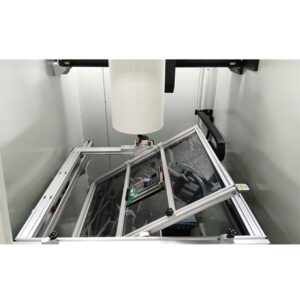

VT-X750

The X750 is used for non-destructive inspection of 5G infrastructure/modules and in-vehicle electrical components as a high-definition, high-quality inspection using full 3D-CT. In recent years, the VT-X750 has been used for inspection of solder voids and solder filling of through-hole connectors in final assembly of power devices such as IGBTs and MOSFETs, which are essential for EVs, as well as Integrated machine and electric power. It has also been widely utilized in the fields of aerospace, industrial equipment, and semiconductors.

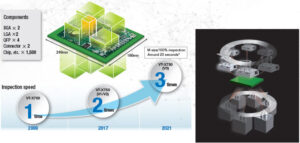

Productivity

Capability

In-line full inspection coverage

The VT-X750 improves upon previous Omron 3D-CT technology making it the fastest X-Ray inspection system to date *¹.

The automated inspection logic has been improved for many parts such as IC heal fillets, stacked devices (PoP), through hole components, press-fit connectors, and other bottom terminated parts.

Increasing automated inspection speed and expanding inspection logic enables full, in-line inspection coverage by 3D-CT method

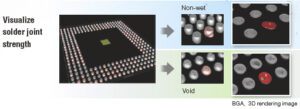

Visualize solder joint strength

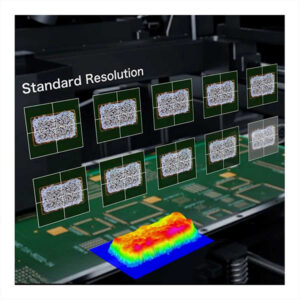

OMRON’s unique 3D-CT reconstruction algorithms provide excellent solder shape recognition and defect detection.

Quantitative analysis allows for an automated inspection process which minimizes the risk of escapes while providing fast and repeatable operation.

Dense and dual sided board design can provide challenges for X-Ray inspection. However, Omron’s 3D-CT technology can overcome such design restraints.

Industries Highest Performing 3D-AXI System:

- Built Upon a History of Omron’s High-Quality Innovation Solutions.

- Fully Automated 3D CT X-Ray Inspection incorporating new AI functionality to support Automated Programming, Fine Tuning, Library

- creation and Optimization of the CT Image.

- CT Technology is Providing Advanced Inspection for Constraint Free PCBA Design.

- Automated Logics combining IPC Standards with Advanced AI Driven Easy Programming Function.

- Fully off-line Programming and Tuning capability for the In-Line Process, without Disturbing Production.

- Complete Inspection Logics for all PCBA devices such as BGA, µBGA, LGA, Flip Chip, PoP, QFN, THT, Press-fit and all discrete devices.

- Full 3D-CT Data Processing and realization of IoT for Manufacturing as found in Industrial 4.0 Smart Factory Solutions.

- VT-X750 is compatible with Omron Advanced Process Software Tools with the goal to achieve Zero Defect Manufacturing.

- Omron Q-upNavi: Combine SPI, AOI and AXI Inspection Result Data for True Root-Cause Process Analysis for Process Improvement.

- Omron Q-upAuto: Advanced Manufacturing Analysis Combining Q-upNavi Inspection Result Data, with Manufacturing Process Data for High Level Process Improvement.

| Item | Description | |||

|---|---|---|---|---|

| Model | VT-X750 | VT-X750-XL | ||

| Type | V3-H | V3-C | V2-H | |

| Inspection object | BGA/CSP, inserted components, SOP, QFP, transistors, R/C chips, bottom-side terminal components, QFN, Power devices, POP, Press-fit CN, etc. |

|||

| Inspection items | Void, open, non-wet, Solder Volume, shifting, foreign object, bridging, Solder fillet, TH Solder filling, Solder ball, etc. (selectable to applications) |

|||

| Imaging system |

Method | 3D-slice imaging by using parallel CT | ||

| Resolution | 6,8,10,15,20,25,30µm/pixel (selectable in the inspection program) |

3, 6,8,10,15,20,25,30µm/pixel (selectable in the inspection program) |

10,15,20,25,30µm/pixel (selectable in the inspection program) |

|

| X-ray source | Micro-fucus closed tube | |||

| X-ray detector | Flat panel detector | |||

| PCBA | Size | 50×50~610x515mm (2×2 to 24×20 inch), Thickness:0.4~5.0mm (0.4~3.0mm in 3 µm resolution) |

100×50~1200x610mm, Thickness:0.4~15.0mm |

|

| Weight | Less than 4.0 kg, less than 8.0 kg (*option) | Less than 15 kg | ||

| Component clearance *Maximum |

Top: 90 mm (*option), Bottom: 40 mm | Top: 40 mm, Bottom: 40 mm | ||

| Warpage | Less than 2.0 mm (Less than 1.0 mm in 3 m resolution) | Less than 3.0 mm | ||

| Main body |

Footprint | 1,550(W) x 1,925(D) x 1,645(H) mm | 2,180(W)×2,510(D)×1,735(H)mm | |

| Weight | Approx. 3,100 kg | Approx. 5,350 kg | ||

| Conveyor height |

900 ±20 mm | |||

| Power supply | Single phase, 200 to 240 VAC, 50/60 Hz | |||

| Rated power | 2.4kVA | 2.58kVA | ||

| X-ray leakage | Less than 0.5 µSv/h | |||

| Air supply | 0.4 to 0.6 Mpa | |||

| Safety standard |

CE, SEMI, NFPA, FDA | CE, SEMI, NFPA, FDA *Under Acquiring |

||

| Brand |

OMRON |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.