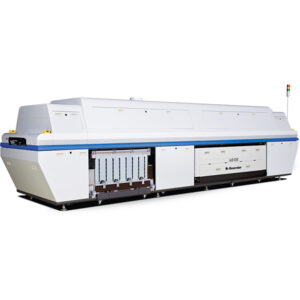

TSM TRA I-F82S Reflow Oven

TSM TRA I-F82S Reflow Oven

- Newly-launched Ultra Low Energy Consumption Air Reflow Oven

- Excellent Thermal management thru RTPM(Real-time Thermal Profile Management)

- Maintenance-free Structure

TSM TRA I-F82S Reflow Oven

TSM TRA I-F82S

Smart Energy saving Air convection Reflow oven

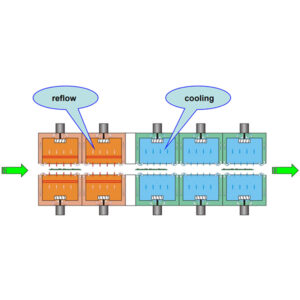

TRA series offers an efficient production method with up and down heating and also can switch heating method beside of a way of up and down. User friendly configured

MMI screen shows a various functions such as temperature monitoring, period of operation maintenance alarm, calibration of temperature and help pop up window for

program running while considered user’s easy access and its convenience in maximum.

The best product is realized thanks to contribution of the lowest temperature deviation, applied for an advanced ultra uniform temperature control system.

RTPM (op), a Real Time Temperature Profile Monitoring System offers abundant information, compatibility and the process index & data chart for analyzing process.

TRA series, the most output to realize, superior performance and Econology

Realize ultra low consumption power in order to reduce CO2, eventually Econology, key words of TRA series under ceaseless technical

development, Partial start-up mode heats up the reflow system in 2 steps to minimize the peak electricity, which greatly saves the operational cost for the factory with lower contracted power. It reduces basic electricity cost and improve efficiency of productivity with weekly timer function, setting equipment operation date and time of its reservation. Also, heating zone is diversified in order to cope with characteristics of production shape of various boards and maximized heating efficiency with newly designed nozzle structure, improved for air flow resistance.

- PCB size (mm): 50 – 460 (500 is optional)

- Heating zone length (mm): 258

- Total heating lenght (mm): 2190

- Top heating zones: 8

- Bottom heating zones: 8

- Cooling zones: 2

- Conveyor type: Chain + PCB ANTI-WARP center support (Chain + Mesh is optional)

- Conveyor speed (m/min): 0.3 – 1.6

- Conveyor height (mm): 900 ± 20

- Temperature accuracy: ± 1ºC

- Temperature repeatability: ± 1ºC

- Warm-up time (min): 30 – 40

- Profile time change (min): 15 – 30

- PCB clearance TOP/BOT (mm): 30/23 (others available on demand)

- Power supply: 3P 220/380V 50/60Hz (others available on demand)

- Power consumption peak/average (kW): 36/10

- Compressed air supply (bar): 5

- Compressed air consumption (Nl/min): up to 105

- Fume extraction (m3/h): 1200

- Overall dimensions L x W x H (mm): 3540 х 1350 х 1450

- Weight (kg): 1300

| Model | TRA I-F82S | TRA I-F82 |

|---|---|---|

| Apparent power (kW) | 34 | 34 |

| Power Consumption (kW) | Approx : 10~ 13kW | Approx : 10~ 13kW |

| Voltage (V) and Power (A) | 220/380 – 89/52 | 220/380 – 89/52 |

| Weight (Kg) | 1630 | 1640 |

| Dimension – LxWxH (meter) | 3.59×1.42×1.5 | 4.05×1.42×1.5 |

| Number of heating zones | 8 | 8 |

| Number of cooling zones | 2 | 2 |

| Cooling Method | Aria | Aria |

| PCB Speed | 0.3-1.6m/min | 0.3-1.6m/min |

| PCB Direction | Right to Left or Left to Right | Right to Left or Left to Right |

| PCB Dimension (mm) | 50~ 450 (option 50~ 550) | 50~ 450 (option 50~ 550) |

| Hot Air Speed | Pre-heat & reflow Approximately 0.5-4.0m/sec | Pre-heat & reflow Approximately 0.5-4.0m/sec |

| Auto stop | Sì | Sì |

| Other Option | PC, UPS, Supporto centrale o Maglia, ecc | PC, UPS, Supporto centrale o Maglia, ecc |

| Brand |

TSM |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.