StartSelective | Selective Soldering | SEHO

StartSelective | Selective Soldering | SEHO

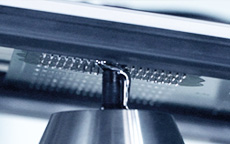

- Optimised soldering area with non-wetted mini-wave solder nozzles, featuring a 7 ° soldering angle.

- The nozzles convince with stable and reproducible flow properties, resulting in high soldering quality.

- Even difficult geometries can be soldered easily.

- Moreover, non-wetted solder nozzles are maintenance-free and feature a nearly unlimited lifetime, thus avoiding follow-up costs.

StartSelective Soldering

StartSelective | Selective Soldering | SEHO

SEHO StartSelective: Connect, Power On and Produce!

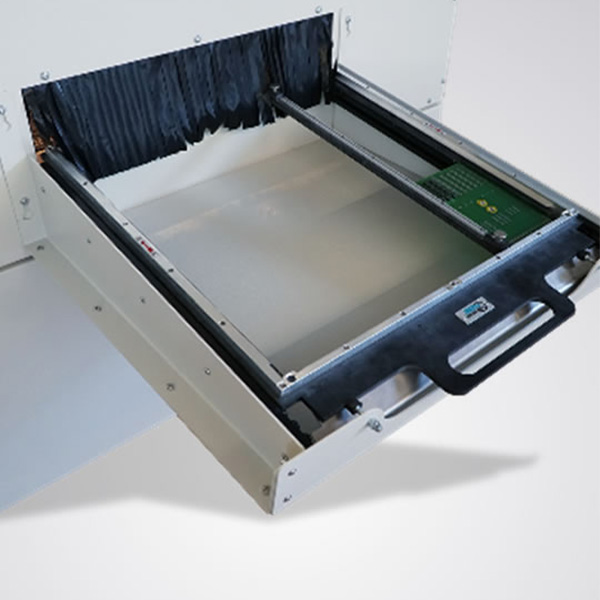

StartSelective is the perfect plug-and-produce selective soldering system for those just entering into automated soldering. The system is fully equipped to start production immediately. This stand-alone machine is thought through down to the last detail, from its compact design, ease of operation and many technical highlights. With a footprint of only 2.5 sqm, the StartSelective provides maximum quality and reproducibility of soldering results as well as an outstanding return on investment.

Ideal for those just entering automated soldering, the StartSelect is the perfect plug-and-produce selective soldering system.With a footprint of only 2.5 m2, the StartSelective provides maximum quality and reproducibility of soldering results for assemblies up to 20 “ x 20 “ and an outstanding return on investment.While all process steps are fully automated and monitored, loading and unloading of assemblies is done manually.

- high precision stand-alone selective soldering system for assemblies up to 508 x 508 mm (20″ x 20″)

- minimum floor space requirements: operation from front side, all set-up and maintenance from right side

- precise micro drop jet fluxer with automatic function control

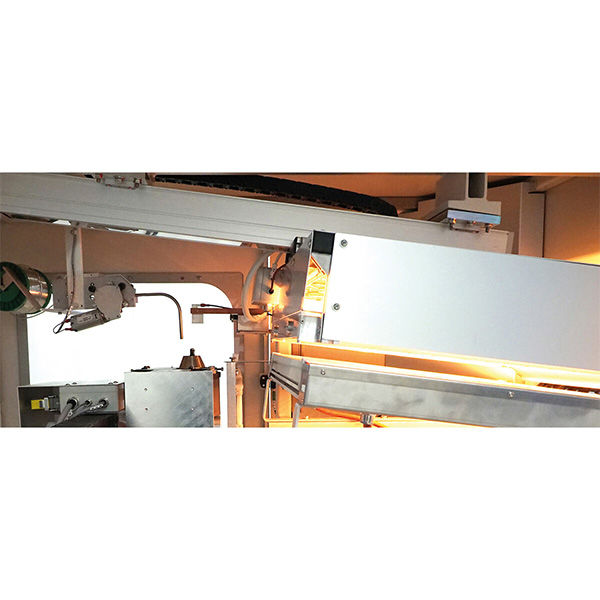

- innovative bottom-side pulsar preheaters, activated in groups of each two

- temperature-controlled top-side IR preheaters

- maximum flexibility due to electromagnetic soldering unit and quickly exchangeable miniwave solder nozzles

- 7° soldering angle = ideal peel-off an perfect soldering results

- no follow-up costs: maintenance-free solder nozzles with nearly unlimited lifetime

- 100 % automated process control

- maximum machine availability: programming is 100 % offline at any PC workplace so that the machine is always available for production

- While all process steps are fully automated and monitored, loading and unloading of assemblies is done manually.

- All process-relevant components such as the micro drop jet fluxer, or the low-maintenance electromagnetic soldering unit have successfully been in use for years in other soldering systems from SEHO.

- The preheat section of the StartSelective is equipped with pulsar heaters over the full area that feature a high energy density and quick reaction time.

- Another highlight is the optimized soldering area with non-wetted miniwave solder nozzles, featuring a 7° soldering angle.

- The nozzles convince with stable and reproducible flow properties resulting in outstanding soldering quality.

- They are maintenance-free and feature a nearly unlimited lifetime, thus avoiding follow-up costs.

| Brand |

SEHO |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.