SMT JUKI RX-8 Assembly Line | Pick and Place Machine

SMT JUKI RX-8 Assembly Line | Pick and Place Machine

- JUKI RX-8 is for all companies that want to make their production line more efficient on smallest shopfloor.

- RX-8 stands for best-in-class output per meter of production line – up to 100,000CPH.

- SMT JUKI | RX-8 dual planet head innovation is number one in area productivity, with taking less line space than only one meter!

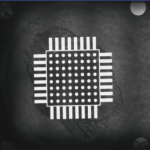

New high accuracy camera for inspection and centering

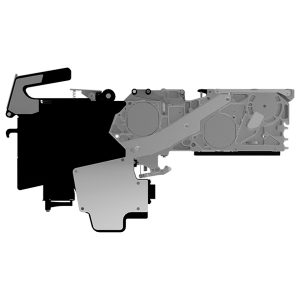

JUKI RX-8 Pick and Place Machine

Component Management with Auto replenishment

JUKI RX-8 Pick and Place Machine is a Top production efficiency is achieved by continuous monitoring of component consumption and communication with the Automated Component Storage and Transport System. When the placement system detects a low-level warning, SMT JUKI RX-8 automatically communicates that information to the storage system, which immediately pulls an additional reel of that component, loads it on an AlV to transport the reel to the line to arrive before the existing reel has run out. This eliminates downtime during production due to component run out.

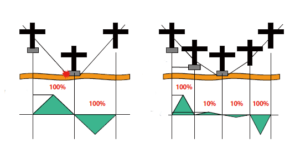

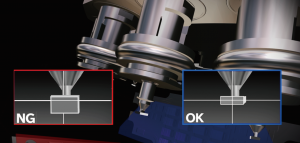

Low impact placement for flexible circuits

Low Impact feature allows separately adjusting the down and up speed of the nozzle during placement. This minimizes the load on the part and on the board during placement.

JUKI RX-8 Pick and Place Machine optimal for placing very small parts that require a lot of accuracy.

JUKI RX-8

- High-speed placements of up to 100,000 CPH.*¹

- Best-in-class placement rate per square meter(sq ft).*²

- Integrates seamlessly with the production enviroment

- Trace Monitor tracks quality throughout production process

- Low impact placement for flexible circuits

- The P20 high-precision planet head is ideal for high speed pocking and placing from a single reel.

- State-of-the-art centering and inspection vision system

- New high accuracy camera for inspection and centering

JUKI High Speed RX-8

| Board Size | 50×50~510mm*¹ *²×450mm |

| Component Height | 3mm |

| Component size | 0201~5mm |

| Placement Speed (optimum) | 100,000CPH |

| Placement Accuracy | ±0.04mm (Cpk -1) |

|

Feeder Supply |

Up to 56 |

| Power Supply | 3Phase AC200V,220V~430V |

| Apparent Power | 2.1kVA |

| Operating air Power | 0.5±0.05MPa |

| Air consumption(standard) | 20L/min ANR (during normal operation) |

| Machine Dimensions(W×D×H) | 998mm×1,895mm×1,530mm |

| Machine Weight | 1,810kg(with fixed bank)/ 1,760kg(with bank changing) |

| Brand |

JUKI |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.