PowerSelective | Selective Soldering | SEHO

PowerSelective | Selective Soldering | SEHO

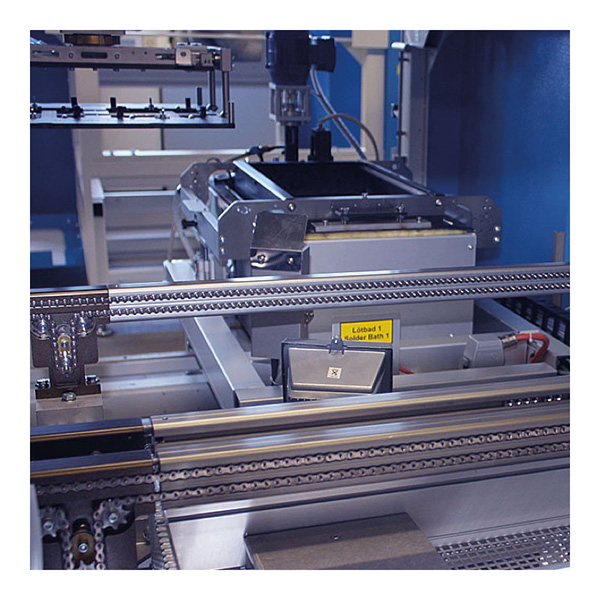

- The machine is equipped with a gripper that allows for angle soldering.

- This solution makes it possible to solder difficult points that cannot be soldered in other machines with a fixed board position.

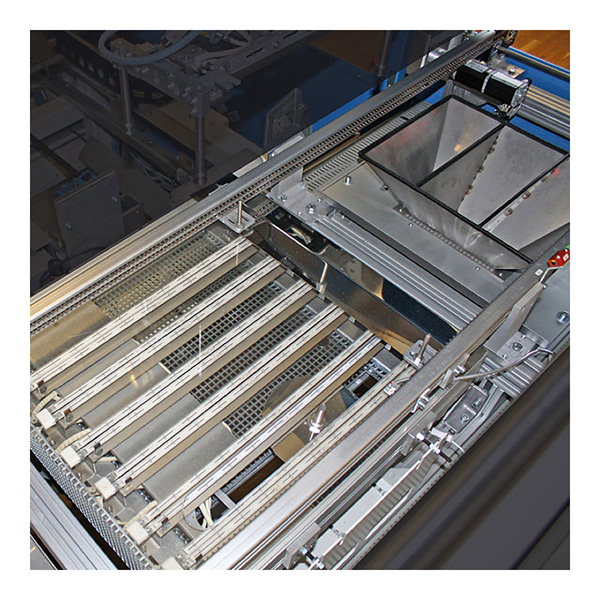

- The machine can be cleaned and maintained without stopping the production.

- PowerSelective can be delivered with a production line tailored to the client’s needs. It is possible to make a line with entry and exit on the same side, which saves space.

PowerSelective | Selective Soldering | SEHO

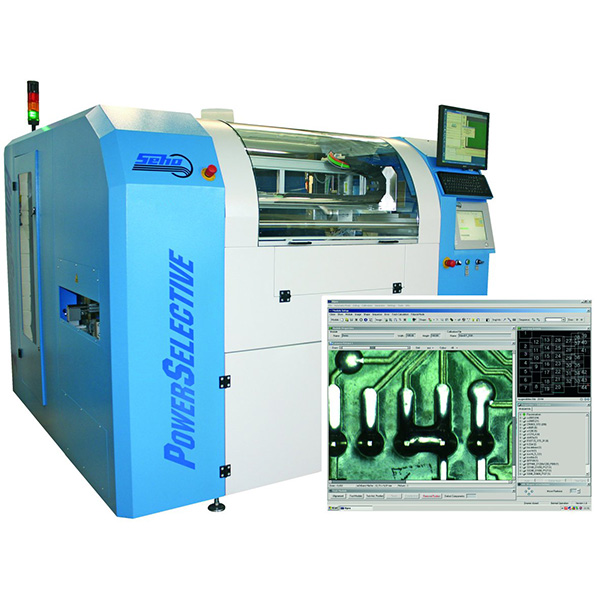

SEHO PowerSelective: For the Flexible Production with High Volumes

The most efficient and flexible machine. Dediated to high-efficiency, high-volume production. It enables to run both miniwave and dip soldering processes. It is possible to install two solder pots (for both process types).

The PowerSelective may be equipped with up to two different soldering units. Thus, miniwave soldering processes, multiwave processes and even conventional wave soldering processes can be covered with only one machine.

PowerSelective is an automated optical inspection system (AOI) that can be embedded directly in the selective soldering process. The system is used for the detection of soldering defects such as non-wetting or insufficient wetting, missing pin or bridging. The inspection begins immediately after the soldering process when the printed circuit board is fixed in the gripper of the soldering machine. The AOI system can be easily integrated into a SEHO PowerSelective, offering remarkable cost savings in relation to floor space and board handling equipment. In the field of wave soldering, SEHO will introduce two new and innovative modules. Special applications such as wave soldering with masks require selective flux application which ensures that only the points to be soldered will be wetted, not the entire mask. This avoids creepage of flux underneath the mask. Simultaneously, flux consumption will be reduced remarkably and the required cleaning cycles for the mask will be decreased. For these applications SEHO developed a coordinate fluxing unit that precisely applies the flux at the previously programmed points only. Other areas on the assembly will not be wetted.

SEHO PowerSelective is featured with an outstanding modular machine construction which ensures highest flexibility. The basic system can ideally be configurated to meet different specific production requirements and it provides the opportunity to be upgraded step by step at a later date to suit subsequent production developments.

Highest Flexibility, absolutely reproducible results, high production volumes and maximum soldering quality sum up to one result: SEHO PowerSelective.

- modular system which ideally fits into each production concept: inline, stand-alone and flexible lean production concepts

- the machine can be upgraded any time to minimize cycle times or to increase the production volume

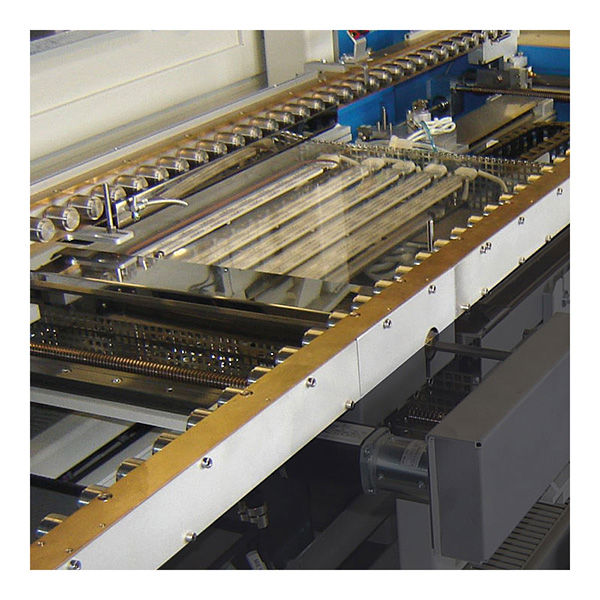

- high precision portal axis system which provides maximum flexibility

- three processes – one machine: for multiwave soldering processes, miniwave soldering and conventional wave soldering processes

- multiple soldering units may be integrated into one machine.

- wetted or non-wetted solder nozzles can be used

- the rotating and tilting function of the gripper allows ideal peel-off to reduce solder bridges

- solder waves with touchless wave height control and nitrogen inertion, for best possible soldering results and highest reliability

- maximum machine availability due to quick change nozzles, and product change-over or maintenance “on-the-fly”

- user-friendly operating interface and easy-to-handle teaching function, online or offline

- 100 % automatic process control with integrated AOI system SEHO PowerVision, flux quantity monitoring and many more

| Brand |

SEHO |

|---|