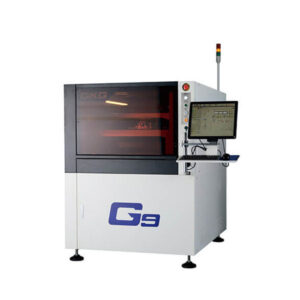

PBT Fa23 | SMT Stencil Printer Semi Automatic

PBT Fa23 | SMT Stencil Printer Semi Automatic

- PBT Fa23 Semi Automatic Printer programmable highly precise and flexible off line stencil printer

- Suitable for SMT production with automatic camera guided alignment

PBT Fa23 Semi Automatic Printer

Fa23 PBT Printer

PBT Fa23

PBT Fa23

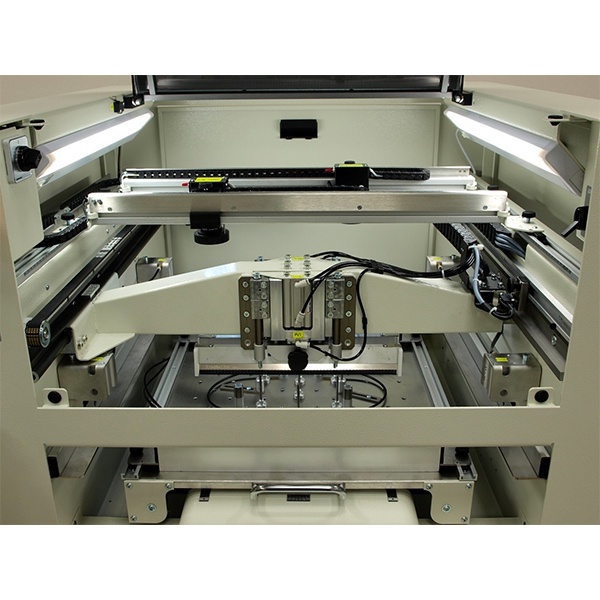

PBT Fa23 Semi Automatic Printer is designed to meet the highest standards of precision and flexibility for small to medium batch production. It is equipped with automatic control of alignment of the stencil apertures relative to the contact pads of the board and a system for cleaning the bottom of the stencil.

Solder paste printing is one of the most important processes in SMT. PBT Fa23 Semi Automatic Printer bring on highly precise print. Designed for accurate and repeatable printing. For any electronic application while maintaining low investment costs.

Two models of Fa23 Printers available to cover complete range of applications

Each model comes as stand-alone with package of selected features

Basic set of adjustable production tooling included

- Compact size and small footprint

- Quick PCB changes due to convenient drawer

- Fast product changeover

- Manual or automatic camera guided stencil to pad alignment

- Digital filtration of unwanted reflections or shapes on the pads chosen for alignment

- X, Y, Theta playless table adjustment

- Quick stencil clamping with pneumatic fixation

- Three-position squeegee height control for quick stencil changes

- Complete set of magnetic PCB fixturing

- Support bars adjustable to PCBA thickness

- Object space up to component height 63,5 mm

- Programmable printing pressure control

- Programmable board from stencil separation speed

- Adjustable separation distance

- Adjustable upper position of the table

- Very smooth pneu-hydraulic synchronized table separation motion

- Programmable print speed and adjustable squeegee range

- Integrated underside cleaning system

- Small to middle series production

- Printing solder paste

- Printing SMD glue

- Printing thermoconductive paste

- Print on ceramics, foils, metals

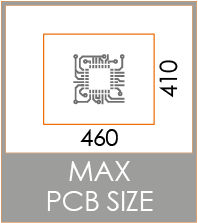

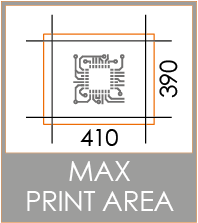

- Print area 410×390 mm

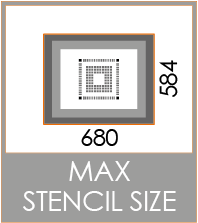

- Frame capacity 680×584 mm

FEATURES FOR PRECISION

Solder paste printing is one of the most important processes in SMT

Fa23 Printers bring on highly precise print

Designed for accurate and repeatable printing

For any electronic application while maintaining low investment costs

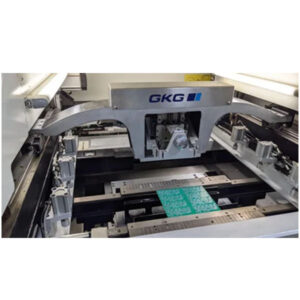

- Stencil-to-board automatic alignment system with unique through-stencil view technology

- Two fixed cameras can be positioned over any suitable position of the print area

- System can use square solder pads or printable fiducials

- Possible exact positioning of PCB under stencil for stencils with reduced apertures

- LED illuminates the target area for a crystal clear view through stencil apertures

- A laser source attached to each camera speeds up navigation and camera positioning during setup

- First print alignment does not require any calibration to define the stencil position

- All to do with the new product is to find the proper apertures for alignment, to show them to the system and start print process

- Alignment in just a few seconds thanks to fast and reliable table servo-positioning with MAXON drives

- Successful snap-off depends on solder paste thixotropy, thickness and dynamics of separation movement

- Separation of stencil from PCB is driven by pneumatic-hydraulic system which assures very smooth acceleration of printable separation speed

- Important for printing of small chips and high-density PCBs

- Slow speed for precise separation is programmable as well as the necessary adjustable snap-off distance, so the separation accelerates as soon as possible to minimize PCB removal time

- After finishing alignment, the PCB-to-stencil position remains without any movement which assures the highest long-term stability of print accuracy

Full range of adjustable parameters assure excellent repeatibility of results

Fa23 series provides high level of programmability and parameter control

INTUITIVE TOUCHSCREEN INTERFACE

- Controlling and programming uses PC with WINDOWS 7 OS

- Possibility of logging all process parameters

- Three levels of operational software with password protected access

- Programmable print speed and pressure

- Digital filtration of non uniform reflection of solder pad surface

- Digital filtration of leads belonging to solder pads chosen for alignment

SQUEEGEE PRESSURE AND SPEED

- Squeegee pressure and speed are programmable and controlled by software

- Dual, friction-free air cylinders assure very precise pressure setting

FLEXIBILITY

PBT Fa23 Semi Automatic Printer come complete with a full supply of magnetic PCB mounting hardware

Wide range of squeegees available

- Easily accessible print head allows quick replacement of squeegee blades

- Metal blade squeegees have integral paste deflectors to keep solder paste contained

- Blades are available in various widths

- Unique design of the Fa23 print head allows fast stencil changes without removing its dual squeegees

- Production mode of the squeegees is either in the Up position or the Down position within the frame envelope

- Up position is designed to keep the solder paste consistent and ready for repeated or next print

| Brand |

PBT Works |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.