Home » Products » THT/DIP Line Solution » Wave Soldering » SE-350 – JT Automation | Wave Soldering | PCB Solder Machine

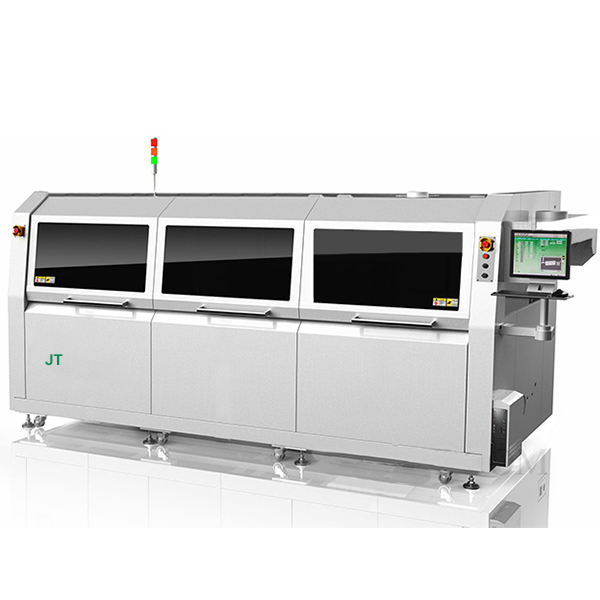

SE-350 – JT Automation | Wave Soldering | PCB Solder Machine

SE-350 – JT Automation | Wave Soldering | PCB Solder Machine

- JT SE-350 Lead-Free Dual Wave Soldering System is Closed loop with inverter control system to keep the stability and accuracy of the conveyor speed.

- The assistant pressure device nearby the entrance to prevent the PCB from slipping.

Category: Wave Soldering

Tags: JT, SE-350, Wave Soldering

Description

SE-350 – JT Automation | Wave Soldering | PCB Solder Machine

JT SE-350

- Closed loop with inverter control system to keep the stability and accuracy of the conveyor speed

- The assistant pressure device nearby the entrance to prevent the PCB from slipping

- Spray nozzle driving by stepping motor is to make sure the coating uniformly

- Module design of spray fluxer system and the design of nozzle always be perpendicular to rail,which can make sure the flux penetrates PCB easily

- Closed loop with inverter control system to keep the stability and accuracy of the conveyor speed

- The assistant pressure device nearby the entrance to prevent the PCB from slipping

- Spray nozzle driving by stepping motor is to make sure the coating uniformly

- Module design of spray fluxer system and the design of nozzle always be perpendicular to rail,which can make sure the flux penetrates PCB easily

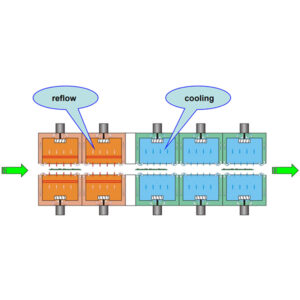

- Forced air cooling system to attain the cold-down slope as per lead-free required

- Conveyor angle is adjustable by manual

- Standard with hot air heating for preheating zones

- Module design suitable for SMT & THT component soldering

- Exhaust adopt centrifugal fan with double filters to avoid any flux drop to PCB

- The level of flux container is controlled by non-contact sensors to ensure nocorrosion and longer life

- Flux spray nozzle with self-cleaning system

- Standard with air knives to prevent flux expand to preheat zone

- Wave height control adopted with inverter, it can be set individually

- 1/4HP high power mechanical pump to meet the wave as high as 15mm

- Light & Sound alarm, emergency stop and over-load protection

| Model No | SE-350 |

| Dimensions (LX wx H) | 4401′ 1582′ 1735m m |

| Weight | Approx. 1800KG |

| Source Power | AC 380V3<1>5W 50/60 Hz; 37 kw (Option: AC 220V 3<1>5 50/60 Hz) |

| Operating Power | Operating Power <9KW |

| Preheating Time | 18min |

| Temperature Range | Room temperature-230″C |

| PCB Width | 50-350mm |

| PCB Clearance | J: 120mm/ T 25mm top 120mm / bottom 25mm |

| Conveyor Direction | L to R (Option: R to L) |

| Conveyor Height | 750±20 mm (Entrance) |

| Conveyor Speed | 300-1800mm/min |

| Heating Zones | 3 bottom hot air preheating zones |

| Temp. Control Mode | PID+SSR |

| Control System | PC +PLC |

| Spray System | Internal Stepping motor spray |

| Conveyor Finger | (60KG) Heavy d uty double hook finger claw |

| Pot Ca pa city | 480kg |

| Pot Operation Mode | Mechanical Pump |

| Pot Material | Cast iron+ Enamel processing |

| Cooling Method | Forced Air Cooling |

Additional information

| Brand |

JT |

|---|

Reviews (0)

Be the first to review “SE-350 – JT Automation | Wave Soldering | PCB Solder Machine” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.