SMD Incoming Material | Essegi Smart Storage Solution

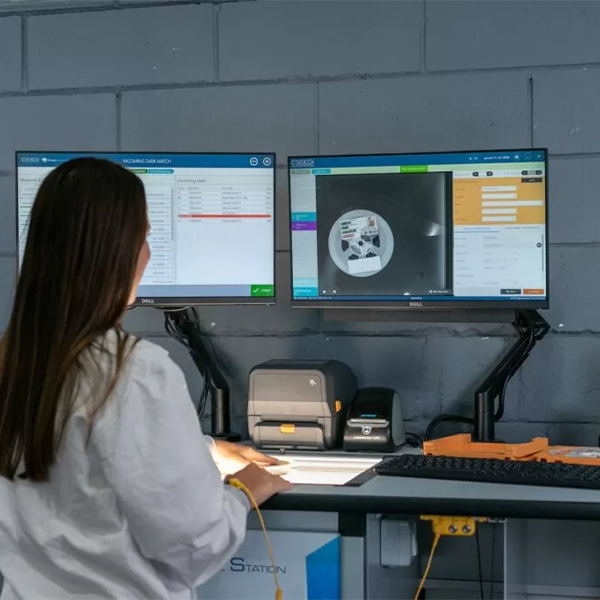

ISM Material Incoming Smart Storage System

- Through the Material Incoming Station operators will speed up material registration activities, avoid mistakes, and increase the traceability of each individual Unique ID.

- sturdy metal structure with antistatic work surface made of static dissipative laminate, with resistivity of 10M Ohm.

- high-resolution camera that allows you to scan the information on the manufacturer’s label.

ISM Material Incoming Station

Smart Storage System | ISM Material Incoming Station

- Track and archive the complete image of the reel and not just the label The camera records and stores the images of the reels placed on the shelf.

- Through the Material Incoming Station operators will speed up material registration activities, avoid mistakes, and increase the traceability of each individual Unique ID.

- With its Auto-Incoming features, it is possible to automatically import information from the supplier and/or customer’s label into the ERP, and print a new Unique ID.

- after setting the rules for each supplier’s label, the operator can simply position the material on the Station and the high-resolution camera will read all the needed codes and information, take a picture for traceability purposes and print the new label.

ISM Material Incoming Station, an incoming goods desk with scanner, helps to automate the incoming goods process and boost productivity dramatically.he primary purpose is to provide a fast and error proof way to generate unique ID labels for use with JUKI’s storage towers. The same label can be used for component setup verification on pick and place lines when combined with optional middleware software.

Validate qualified and approved part numbers

The ISM software checks the correspondence between the item codes of the new incoming material against a list of approved item codes. The software will prevent initialization of material that is not in the approved part number list ensuring extreme process and product quality.

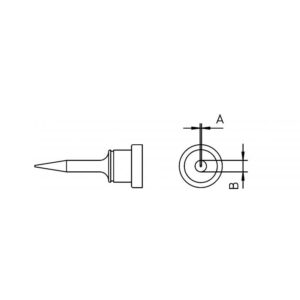

It recognizes, analyses and stores 1D / 2D codes on the top of the reels

The camera and software are able to recognize, analyze and store any 1D / 2D code on the top of the reels. The software is set up with standard rules used by most component suppliers to label their products. It manages in an advanced way the information present on the transport documents.

- The system recognizes all standard barcodes thanks to a high-resolution camera replacing time-consuming teaching of the system.

- The flexible recognition rules can certainly be adopted to previously used barcodes to adopt the system to existing processes.

The Unique ID provides for easy identification and traceability of material in the production process – from storage to setup up to production. Thus, it can be validated easily at any time if material was produced, stored, transported, used or spent.

- Full connection and integration with ERP software automates manual tasks and improves overall inventory visibility.

- Every time a new reel is created, it can be added to ERP records.

- When reels are moved from the towers to other positions, ERP will be notified. Optional software can also verify the receipt of new materials against purchase orders to ensure all items were received correctly and also combine receiving with labeling to save time.

- Complete integration of warehouses with production lines and management software.

- Use of fully automatic systems or LED systems and acoustic signals.

- Reduction of the possibility of picking errors by the operator.

- Control of the exact quantity used for each component.

- Elimination of paper documents.

| Hardware | IMS Incoming Material |

| ESD Table | ✓ |

| Touch screen, keyboard, mouse | ✓ |

| 20 MP High resolution camera | ✓ |

| Label Printer | ✓ |

| 1D / 2D barcode scanner | ✓ |

| PC i7, 8 GB RAM 256 GB | ✓ |

| Software Console | ✓ |

| Halcon 1D-2D library | ✓ |

| Auto-incoming software | ✓ |

| Picture traceability option |

✓ |

| Technical Data | IMS Incoming Material |

| Dimensions | Width = 1,6 m / 5.25 ft

Depth = 0,8 m / 2.62 ft |

| Operating Height | 1,1 m (3.28ft) |

| Weight | 101 kg – 222.67 kg (Full cases) |

| Power consumption | 100-240V – Imax: 5A – Fequency 50-60 Hz |

| Operating System | Microsoft Win 10 |

| Brand |

Essegi |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.