Home » Products » SMT Line Machine » Reflow Oven » GoReflow | Reflow Soldering |SEHO

GoReflow | Reflow Soldering |SEHO

Reflow Soldering |SEHO

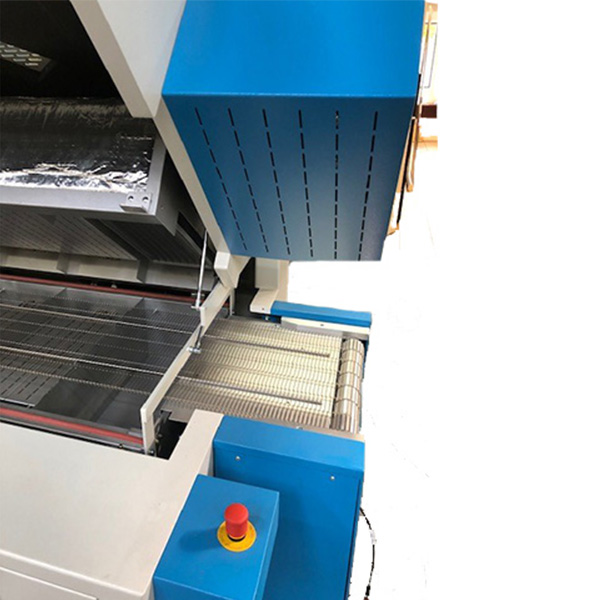

- With an active heating zone length of 2700 mm [106.3″], the convection reflow soldering system GoReflow-plus is ideally suited for medium-sized production series that require high soldering quality and high flexibility in terms of temperature profiling

Category: Reflow Oven

Tags: GoReflow, SEHO, Selective Soldering

Description

GoReflow | Reflow Soldering |SEHO

Attractive Performance – Attractive Design – Attractive Price

- With a heating zone length of 1850 mm (72.8″) or 2350 mm (92.5″) the convection reflow soldering systems GoReflow 1.8 and GoReflow 2.3 are ideally suited for small to medium-sized production series.

- The machines are not only featured with an outstanding attractive design, above all the systems convince with their well-engineered concept and excellent soldering results.

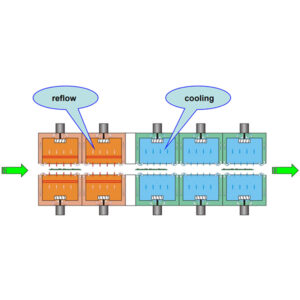

5 respectively 7 heating zones provide maximum flexibility in temperature profiling, particularly for lead-free soldering processes.The Systems are designed for soldering in ambient atmosphere, however, if needed they also may be equipped with a local nitrogen inertion in the peak area.Of course, the systems are provided with an up-to-date control unit for easy and quick programming and they may be integrated into a fully automated production line.

- compact machine technology for small and medium-sized production series

- high number of heating zones, exclusively with full convection, to guarantee perfect soldering results

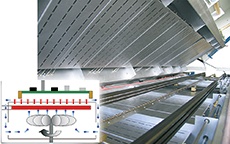

- efficient and homogeneous energy transfer with optimized process gas circulation

- flux management system ensures minimum maintenance requirements

- low costs of ownership

- high process reliability

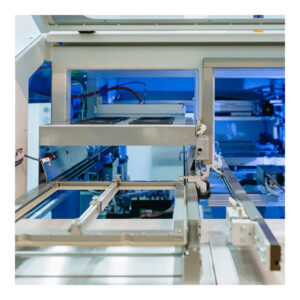

- inline integration with matching interfaces

- unbeatable price-performance ratio

|

Heating Zones |

GoReflow 1.8 |

GoReflow 2.3 |

| process gas | air | air |

| total number of heating zones top / bottom | 5 / 2 | 7 / 2 |

| number of preheat zones top / bottom | 3 / 0 | 5/ 0 |

| number of peak zones top / bottom | 2 / 2 | 2 / 2 |

| heating zones in the bottom preheat area |

|

|

| total length of heated area [mm / inch] | 1850 / 72.8 | 2350 / 92.5 |

| average working speed [m/min] | 0.40 – 0.55 | 0.55 – 0.70 |

| time for heating up [min] | approx. 30 | approx. 30 |

| Available Conveyor Systems | ||

| belt conveyor – max. working width [mm / inch] | 410 / 16.14 | 410 / 16.14 |

| chain conveyor – max. working width [mm / inch] | 410 / 16.14 | 410 / 16.14 |

| electrical width adjustment |

|

|

| chain center support, electrical width adjustment |

|

|

| max. lowering of center support [mm/inch] | 18 / 0.7 | 18 / 0.7 |

| combined conveyor-max. working width [mm/inch] | 410 / 16.14 | 410 / 16.14 |

|

Cooling Area |

||

| number of cooling zones [pcs] | 2 | 2 |

| length of cooling area [mm / inch] | 600 / 23.6 | 600 / 23.6 |

| fan cooling unit circulating ambient air |

|

|

|

Flux Management |

||

| flux management system with stainless steel filter |

|

|

|

Control Unit |

||

| micro processor control |

|

|

| operation via touch display |

|

|

| management data system according to ISO 9000 ff | via interface | via interface |

| clock timer |

|

|

| interface for inline integration (SMEMA) |

|

|

| closed loop control of all relevant functions |

|

|

| PCB pass-through control |

|

|

| capacity for 100 soldering programs |

|

|

|

Machine Dimensions |

||

| length [mm / inch] | 3200 / 125.98 | 3700 / 145.67 |

| width [mm / inch] | 1250 / 49.21 | 1250 / 49.21 |

| height [mm / inch] | 1600 / 62.99 | 1600 / 62.99 |

Additional information

| Brand |

SEHO |

|---|