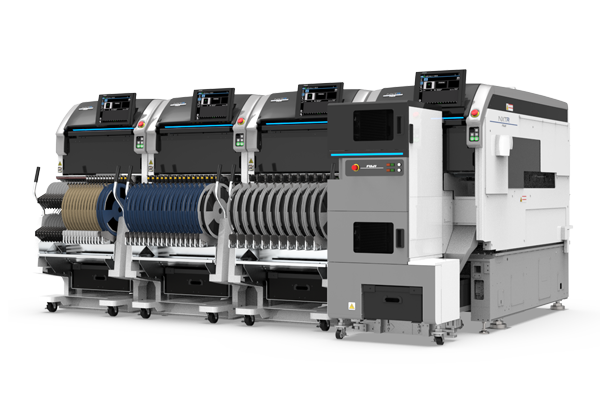

FUJI NXT-R SMT Machine

FUJI NXTR SMT Machine

- FUJI NXT-R SMT Machine offers a truly modular design for the optimal line configuration that caters to your production.

- Real-time sensing placement, optimized placement actions, and part handling checks after placement are just a few examples.

- This high-end model machine from the NXT series supports new functions that preserve a high level of QCD performance

FUJI NXTR SMT Machine

FUJI NXTR SMT Machine

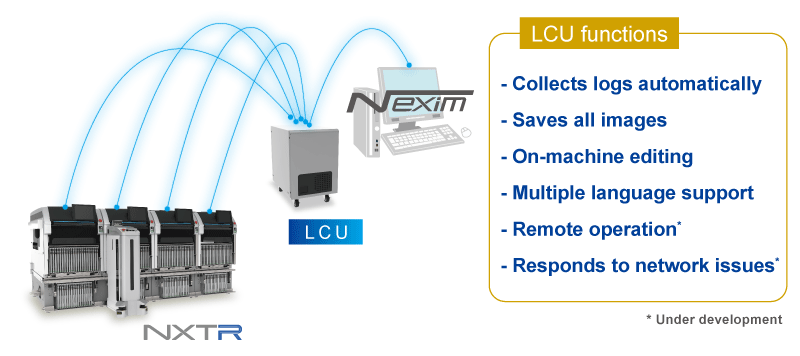

In order to minimize the gap between the plan and reality while maintaining efficient production, optimum production schedules that include the flow of materials need to be implemented and met in actual production. FUJI Smart Factory Platform NXTR is a new platform that is able to link with the integrated production system, Nexim, for efficiently performing a wide range of production.

SMT Pick and Place – NXTR

FUJI NXTR SMT Machine is a high-end model placement machine that pursues placement quality and productivity through expanding supported panel sizes and part handling capability and enhancing data processing while continuing the popular Fuji concepts — compact, high area productivity, single side operation, modular, and simple operation.The newly developed automatic feeder exchange system frees operators from changeover and supply work. Fuji is paving the way to the future of Smart Factories with NXTR.

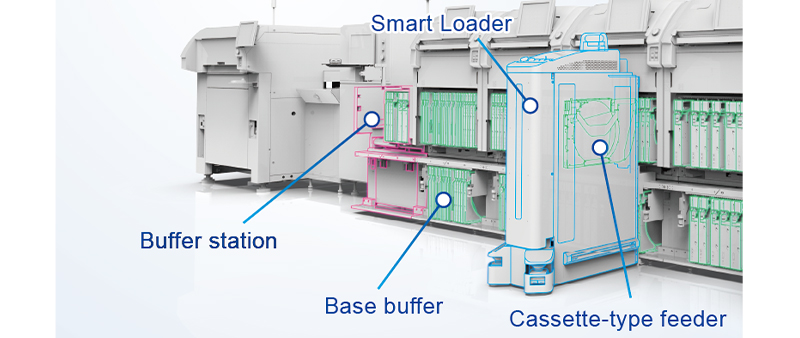

Automatic feeder exchange

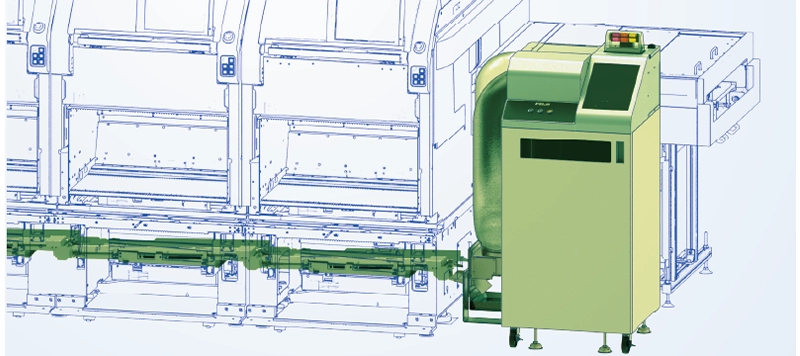

FUJI NXTR SMT Machine Because the Smart Loader performs changeover and part supply according to the schedule, the amount of work at the line side can be reduced and efficient production can be achieved.

By simply setting cassette-type feeders at buffer stations, the Smart Loader automatically exchanges the feeders in production slots and base buffers according to parts out warnings and the changeover schedule.

Smart Loaders exchange feeders during production, preventing production stops. A production method in which parts are supplied from the base buffer during production is effective for mass production.

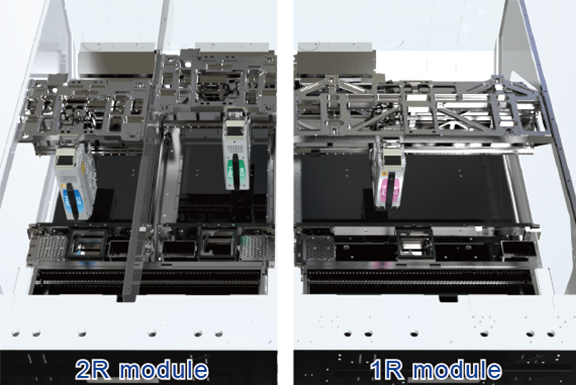

Modular concept

FUJI NXTR SMT Machine continues the concept of true modularity from the NXT series. This true modularity is a unique feature to Fuji and none of our competitors can match it.

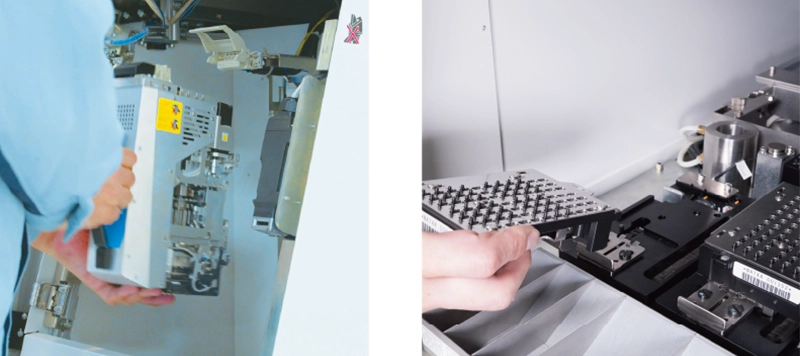

Fuji’s original compact lightweight heads can be easily exchanged without using tools. This allows operators to perform maintenance and troubleshoot unexpected problems.

Configuratio optimal production

The quantity of robots per module and types of heads used can be selected to match your product, giving you the optimal production equipment.

Additional investment can be made on the scale of single modules. You can gradually increase the production capacity to the necessary extent with minimal investment for each.

The modules are designed for single side operation that streamlines and optimizes the operation traffic.This increases efficiency in supplying materials and performing maintenance work.

High quality placement

Maintaining a high level of quality on all placements.

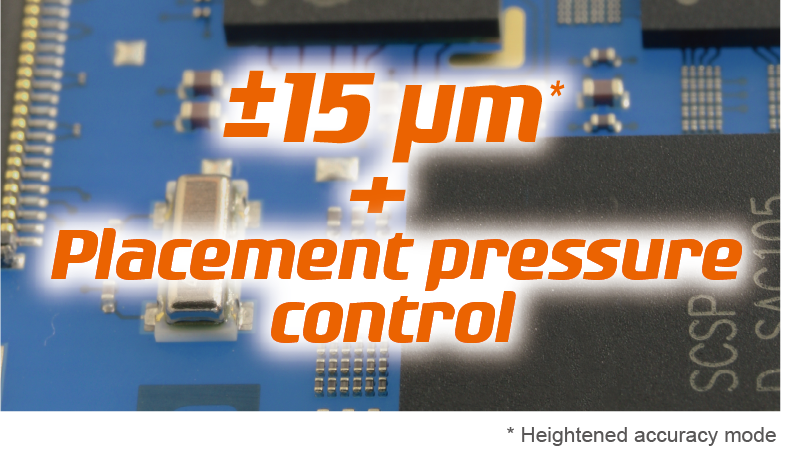

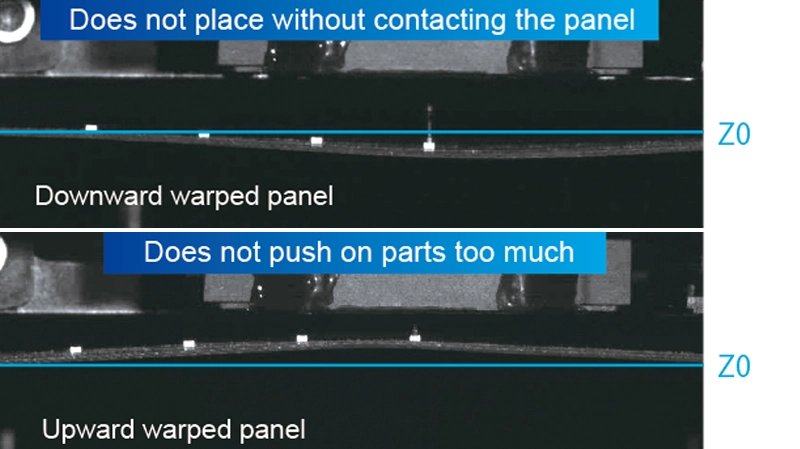

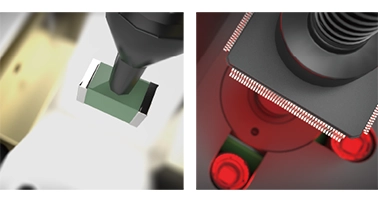

Placements can be performed with an accuracy of ±25 µm at all times without constraints for the head type or the parts to be placed. For parts requiring higher accuracy, placement with an accuracy of ±15 µm is possible by using heightened accuracy mode. Additionally, controlling the push-in amount during placement allows for placement with the appropriate pressure.

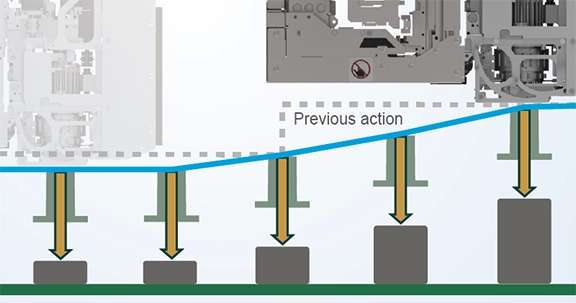

Placement height adjustment

The placement stroke follows changes in the placement height due to panel warpage and distortions, which allows the machine to control the appropriate push-in amount and moreover prevents placement deviations and excess stress on parts and panels.

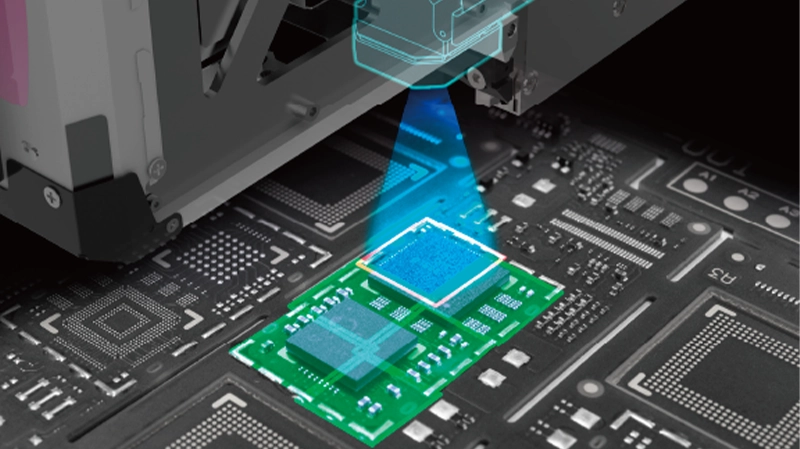

Mark and parts inspection (MPI) Various checks are available within placement machines to verify the process result shortly after that process: Checking placement immediately following placement, and checking placed parts before placing shield parts, for example. This prevents production of defective products and reduces wasted time and parts.

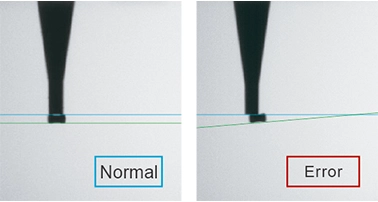

Intelligent parts sensor (IPS)

The installed IPS system can cater to a wide range of checks, from part pickup stance to parts remaining on nozzles, as well as upside-down checks for minimold parts. It prevents placement defects attributed to packaging, nozzles, and parts.

LCR check, 3D coplanarity check

Placement defects caused by operation errors and defective parts are prevented by checking the electrical properties of chip parts with LCR checks and by checking the leads and bumps on IC parts with coplanarity checks. (Option)

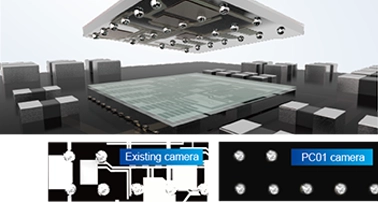

The camera equipped with advanced lighting technology, ensures reliable vision processing of WL-CSPs and other parts for which the background of parts are likely to be captured in acquired images. Using a high-resolution camera enables reliable recognition of bumps as small as 45 µm in diameter. This results in high accuracy placement.

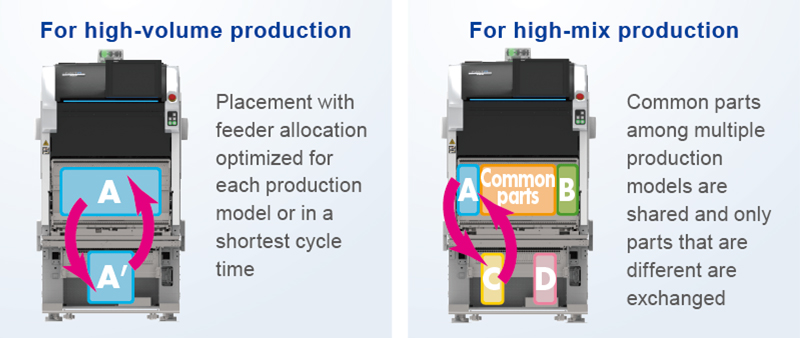

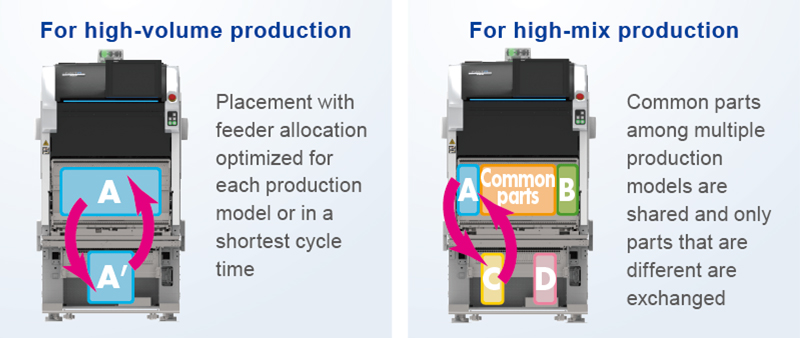

Support for various production types

Building production lines with the flexibility to handle various types of production.

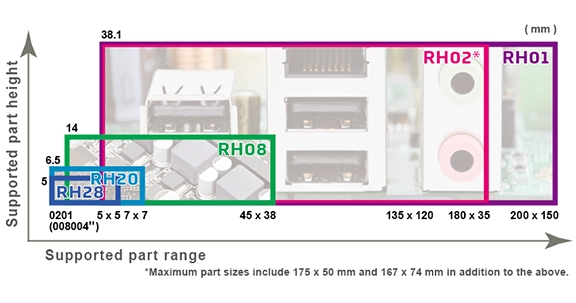

The newly-developed heads are capable of handling an expanded part range. They contribute to line balancing and flexible production without drops in production rates even when a different set of parts is used in the next production.

Fuji’s unique rotary head technology with simultaneous pickup and improved feeder indexing speed provides 60,000 cph per robot.This industry-leading placement speed takes productivity to the next level.

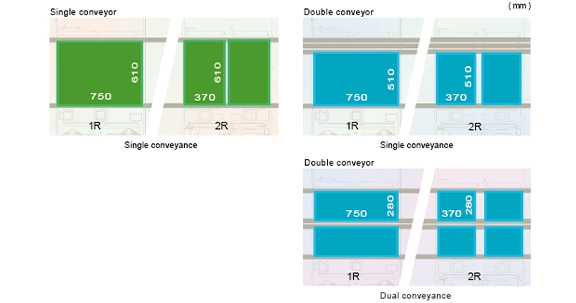

The panel size coverage is expanded so that panels up to 750 x 610 mm are supported “with single conveyors” and up to 370 x 280 mm “with double conveyors” when using dual lane production. From large panel production to highly-efficient production of producing panels in the same size, NXTR line configurations are capable of supporting a greater variety of production.

Operation can be optimized in various ways to suit the part being placed, such as by selecting stable and optimal operation speeds and streamlining Z direction strokes in view of the part height. In addition to making it possible to support various parts, this also improves cycle time as well.

– Multi-level transfer speed

– Shortest Z stroke control

The appropriate hard-type or soft-type backup pins are allocated automatically.This function is an effective measure to reduce work and prevent mistakes during changeover. (Option)

– Program-based positioning

– Auto allocation position check

Utilizing specialized feeders and base buffers greatly increases the quantity of parts that can be loaded. When combined with the Smart Loader, these support a wide range of production.

Evolving manufacturing

Responding to evolving parts and production models, and advancing total line efficiency.

By automatically saving logs and image data, signs of issues that would cause machine stops and information that would lead to problem solving are not missed, leading to error prevention and faster recovery times.

Waste tape is collected automatically into one place to reduce operator work that previously needed to be performed regularly for each module.

Pulling forward the module opens up access to the inside the machine with ease from both sides. This makes it possible to exchange heads and other units and perform maintenance work with a comfortable posture.

Nozzles and also heads can have maintenance performed offline. Using automation units ensures reliable maintenance without requiring any skills. Linking these units with Nexim improves maintenance management.

NXT-R A Model

NXT-R S Model

| Brand |

FUJI |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.