FUJI NXT III | Fuji Scalable Placement Platform

FUJI NXT III | Fuji Scalable Placement Platform

- Like its predecessors, the FUJI NXT III has a variety of reconfigurable options including numerous types of positioning heads, various types of canister, pallet and belt feeders.

- Thanks to the possibility of a free choice of different types of installation modules and heads FUJI NXT III , users can create a machine configuration that is optimal for any type of product and production program.

Their big advantage:

- SHORTENING THE LINE LENGTH

- CONSISTENT SOFTWARE

- SIMPLIFIED OPERATION

- REDUCTION IN MAINTENANCE EXPENSE

FUJI NXT III | Fuji Scalable Placement Platform

With the NXT III/IIIc, Fuji developed the 3rd generation of the highly successful NXT series, with more than 66,000 installed modules worldwide.

For multi functional and high-performance electronics, such as in mobile phones and automotive applications, both the number of components to be assembled, as well as the possible functionalities further increased. Accordingly, the assembly density of tiny components increases sharply. On the other hand, requirements such as the assembly of shielding plates, components with a very small grid connection and components of package-on-package applications show the requirements for the functionality of assembly machines are becoming more and more demanding year after year.

The NXT III/IIIc has been designed as a scalable placement platform that delivers both high productivity and quality, which also meets the needs of future generations of components (such as 03015).

In addition, it ensures high compatibility with its predecessor NXT II. Many existing machine elements, such as placement heads, tray and feeder units, can be used even on the NXT III/IIIc.

FUJI NXT III

- Perfect for high-volume production and high product mix

- new servo control for even faster and more accurate motor control

- New, more stable design of the X / Y axes and the machine frame for greater speed and higher precision

- further improvement in the throughput of the entire component spectrum of 03015, medium and large components by using the new “Flying Vision System”

- Support the next generation component (03015) by the new, super-fast placement H24S (24 Nozzles, 35,000 CPH) and even faster feeders W08f

- Intuitive and easy to use machine with Touch Panel Interface

- Scalable depending on the required feeder positions and throughput

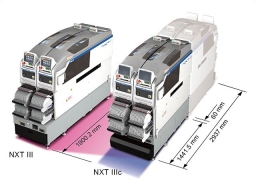

- 2 types of modules: M3 (width 325mm, 20 pitches Feeder) or M6 (width 650 mm, 45 pitches Feeder)

- Exchange of Heads in minutes without tools

- Replacement of feeder during production without stopping the machine is possible

- Compatible with the AIMEX-series

By using the appropriate placement heads, each NXT III/IIIc module can be customized according to your production conditions. The NXT III/IIIc thus covers your entire component spectrum.

The platform allows not only assembly but also the integration of additional functions:

- Glue dispensation

- 3D Solder Paste Inspection

- Component Inspectio

The best floorspace productivity in the industry

One NXT IIIc module occupies just 0.

Part supply without stopping the machine

As with the FUJI NXT III, feeders on the NXT IIIc can be added and removed during production, meaning that you can resupply parts without interrupting production. Tray parts can also be resupplied during production. As a further option to ensure smooth and uninterrupted part supply, splicing is also supported.

| M3 III | M6 III | |

|---|---|---|

| APPLICABLE PCB SIZE (L X W) |

48 x 48 mm to 250 x 510 mm (double conveyor)* 48 x 48 mm to 250 x 610 mm (single conveyor) *Double conveyors can handle PCBs up to 280 (W) mm. PCBs larger than 280 (W) mm must be produced by changing the double conveyor to single lane production mode. |

48 x 48 mm to 534 x 510 mm (double conveyor)* 48 x 48 mm to 534 x 610 mm (single conveyor) *Double conveyors can handle PCBs up to 280 (W) mm. PCBs larger than 280 (W) mm must be produced by changing the double conveyor to single lane production mode. |

| PART TYPES | Up to 20 types of parts (calculated using 8 mm tape) | Up to 45 types of parts (calculated using 8 mm tape) |

| PCB LOADING TIME | For double conveyor: 0 sec (continuous operation) For single conveyor: 2.5 sec (transport between M3 III modules), 3.4 sec (transport between M6 III modules) |

For double conveyor: 0 sec (continuous operation) For single conveyor: 2.5 sec (transport between M3 III modules), 3.4 sec (transport between M6 III modules) |

| PLACEMENT ACCURACY (FIDUCIAL MARK STANDARD) * THE PLACING ACCURACY IS OBTAINED FROM TESTS CONDUCTED BY FUJI. |

H24G : +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode) (3sigma) cpk≥1.00 V12/H12HS : +/-0.038 (+/-0.050) mm (3sigma) cpk≥1.00 H04S/H04SF : +/-0.040 mm (3sigma) cpk≥1.00 H08/H04 : +/-0.050 mm (3sigma) cpk≥1.00 H02/H01/G04 : +/-0.030 mm (3sigma) cpk≥1.00 H02F/G04F : +/-0.025 mm (3sigma) cpk≥1.00 GL : +/-0.100 mm (3sigma) cpk≥1.00 |

H24G : +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode) (3sigma) cpk≥1.00 V12/H12HS : +/-0.038 (+/-0.050) mm (3sigma) cpk≥1.00 H08M/H04S/H04SF : +/-0.040 mm (3sigma) cpk≥1.00 H08/H04/OF : +/-0.050 mm (3sigma) cpk≥1.00 H02/H01/G04 : +/-0.030 mm (3sigma) cpk≥1.00 H02F/G04F : +/-0.025 mm (3sigma) cpk≥1.00 GL : +/-0.100 mm (3sigma) cpk≥1.00 |

| PRODUCTIVITY * THE THROUGHPUT ABOVE IS BASED ON TESTS CONDUCTED AT FUJI. |

H24G: 37,500 cph (Productivity priority mode) / 35,000 cph (Standard mode) V12: 26,000 cph H12HS: 24,500 cph H08: 11,500 cph H04: 6,500 cph H04S: 9,500 cph H04SF: 10,500 cph H02: 5,500 cph H02F: 6,700 cph H01: 4,200 cph G04: 7,500 cph G04F: 7,500 cph GL: 16,363 dph (0.22 sec/dot) |

H24G: 37,500 cph (Productivity priority mode) / 35,000 cph (Standard mode) V12: 26,000 cph H12HS: 24,500 cph H08M: 13,000 cph H08: 11,500 cph H04: 6,500 cph H04S: 9,500 cph H04SF: 10,500 cph H02: 5,500 cph H02F: 6,700 cph H01: 4,200 cph G04: 7,500 cph G04F: 7,500 cph 0F: 3,000 cph GL: 16,363 dph (0.22 sec/dot) |

| SUPPORTED PARTS | H24G: 03015 to 5 x 5 mm, Height: up to 2.0 mm V12/H12HS: 0402 to 7.5 x 7.5 mm, Height: up to 3.0 mm H08M: 0603 to 45 x 45 mm,Height: up to 13.0 mm H08: 0402 to 12 x 12 mm, Height: up to 6.5 mm H04: 1608 to 38 x 38 mm, Height: up to 9.5 mm H04S/H04SF: 1608 to 38 x 38 mm, Height: up to 6.5 mm H02/H02F/H01/0F: 1608 to 74 x 74 mm (32 x 180 mm), Height: up to 25.4 mm G04/G04F: 0402 to 15 x 15 mm, Height: up to 6.5 mm |

H24G: 03015 to 5 x 5 mm, Height: up to 2.0 mm V12/H12HS: 0402 to 7.5 x 7.5 mm, Height: up to 3.0 mm H08M: 0603 to 45 x 45 mm,Height: up to 13.0 mm H08: 0402 to 12 x 12 mm, Height: up to 6.5 mm H04: 1608 to 38 x 38 mm, Height: up to 9.5 mm H04S/H04SF: 1608 to 38 x 38 mm, Height: up to 6.5 mm H02/H02F/H01/0F: 1608 to 74 x 74 mm (32 x 180 mm), Height: up to 25.4 mm G04/G04F: 0402 to 15 x 15 mm, Height: up to 6.5 mm |

| MODULE WIDTH | 320 mm | 645 mm |

| MACHINE DIMENSIONS | L: 1295 mm (M3 III x 4, M6 III x 2) / 645 mm (M3 III x 2, M6 III) W: 1900.2 mm, H: 1476 mm |

L: 1295 mm (M3 III x 4, M6 III x 2) / 645 mm (M3 III x 2, M6 III) W: 1900.2 mm, H: 1476 mm |

| DYNAHEAD(DX) | |||

|---|---|---|---|

| NOZZLE QUANTITY | 12 | 4 | 1 |

| THROUGHPUT (CPH) | 25,000 Parts presence function ON: 24,000 |

11,000 | 4,700 |

| PART SIZE (MM) |

0402 (01005″) to 7.5 x 7.5 Height: Up to 3.0 mm |

1608 (0603″) to 15 x 15 Height: Up to 6.5 mm |

1608 (0603″) to 74 x 74 (32 x 100) Height: Up to 25.4 mm |

| PLACING ACCURACY (FIDUCIAL MARK BASED REFERENCING) |

+/-0.038 (+/-0.050) mm (3σ) cpk≥1.00* *+/-0.038 mm obtained with rectangular chip placement (high accuracy tuning) under optimal conditions at Fuji. |

+/-0.040 mm (3σ) cpk≥1.00 | +/-0.030 mm (3σ) cpk≥1.00 |

| PART PRESENCE CHECK |

o | x | o |

| PARTS SUPPLY TAPE |

o | o | o |

| PARTS SUPPLY STICK |

x | o | o |

| PARTS SUPPLY TRAY |

x | o | o |

| PARTS SUPPLY SYSTEM | |

|---|---|

| LNTELLIGENT FEEDERS | Support for 4, 8, 12, 16, 24, 32, 44, 56, 72, 88, and 104 mm wide tape |

| STICK FEEDERS | 4 ≤ Part width ≤ 15 mm (6 ≤ Stick width ≤ 18 mm), 15 ≤ Part width ≤ 32 mm (18 ≤ Stick width ≤ 36 mm) |

| TRAYS | Applicable tray size: 135.9 x 322.6 mm (JEDEC standard) (Tray Unit-M),276 x 330 mm (Tray Unit- LT), 143 x 330 mm (Tray Unit-LTC) |

| Brand |

FUJI |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.