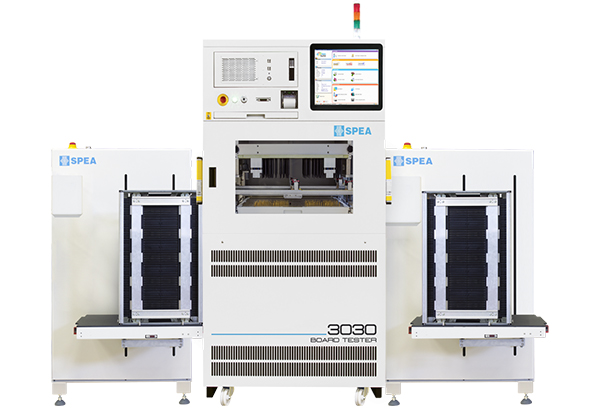

3030IL SPEA | Automatic Inline Multi Function Board Tester

3030IL Automatic Board Tester Machine | ICT Test System

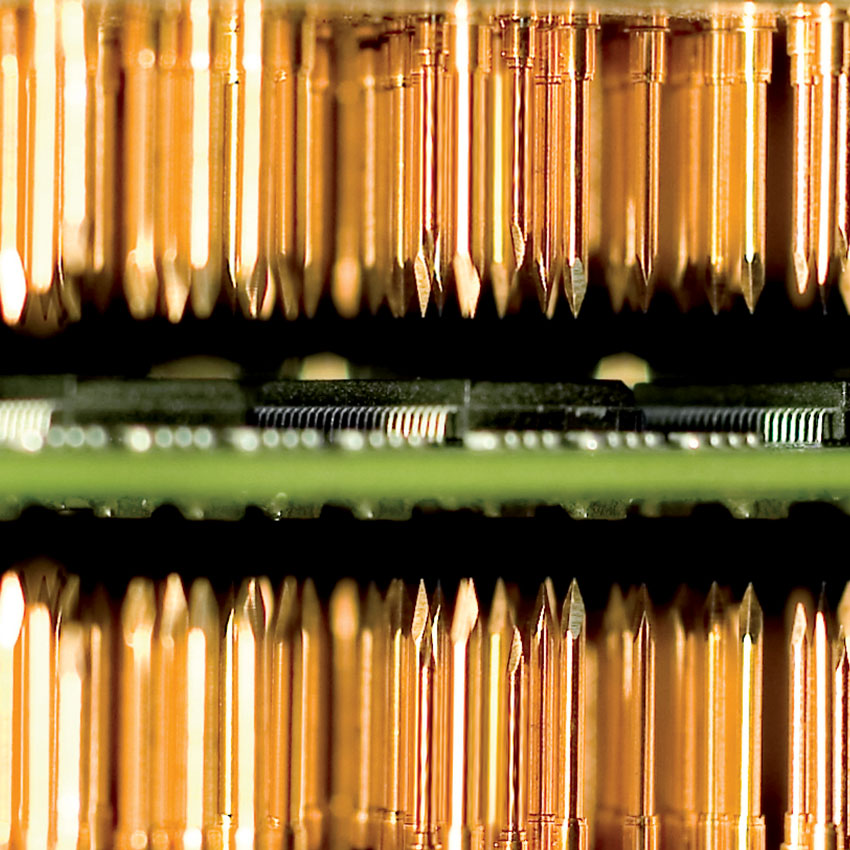

- 3030IL is the fully automatic bed-of-nails tester expressly designed to minimize the cost of test, providing unparalleled throughput without requiring the operator to load the PCB or perform the test.

- Multi-core multi-function board tester.

- 4x parallel test. Ultra-fast handling.

- Minimize the cost of test.

3030IL Automatic Board Tester

ICT Test System Machine | 3030IL Automatic Board Tester

- 3030IL is the fully automatic bed-of-nails tester expressly designed to minimize the cost of test, providing unparalleled throughput without requiring the operator to load the PCB or perform the test.

- Modular and fully upgradable, 3030IL combines a wide range of test capabilities in a unique, integrated, high-throughput, cost-effective system.

- It can be quickly integrated into SMEMA production lines, or used with standard automatic board loaders/unloaders.

- 4x parallel test. Ultra-fast handling.

3030IL can be equipped with up to 4 independent test cores – each one with independent CPU, local memory and instrumentation – able to test in parallel up to 4 boards/panels of boards.

Compared to standard ICT testers, 3030IL throughput is up to 400% higher, thus minimizing the cost of test.

SAVE MONEY

Why buy several pieces of equipment when you just need one?

By using 3030IL, multiple test techniques are executed within a unique system. Compared to multiple test stations, the benefits are huge: no operator, a single test program, reduced industrial space, faster training and lower operational costs.

SAVE TIME

The required test time is greatly reduced by 3030IL.

First of all, expensive and unnecessary handling operations are avoided. With just one board loading/unloading the tester performs different tests in a optimized way, in order to avoid redundancy and overtest of your product, thus allowing you to save precious time.

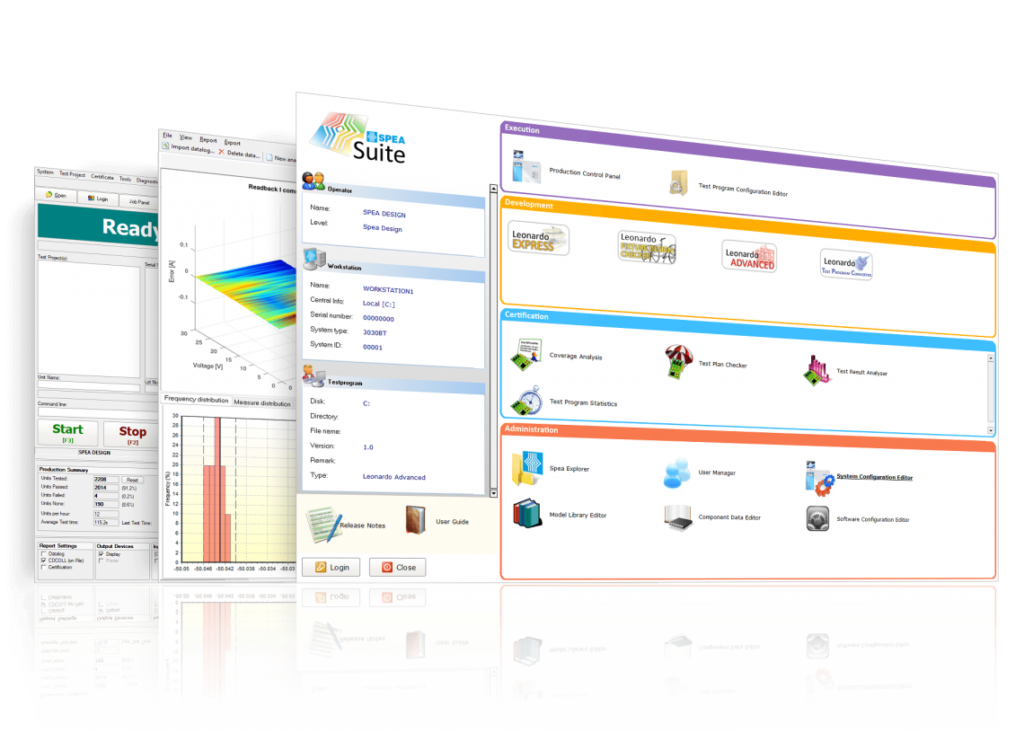

And what about programming multiple equipment? With 3030IL and Leonardo OS you just need a few minutes to generate your multifunction test program.

SAVE FIELD RETURNS

3030IL has been designed to help electronics manufacturers increase their product quality.

By executing various test techniques with the same tester used for ICT, all risks related to subsequent handling operations are avoided. At the end of the test the product is ready to be delivered to the final customer.

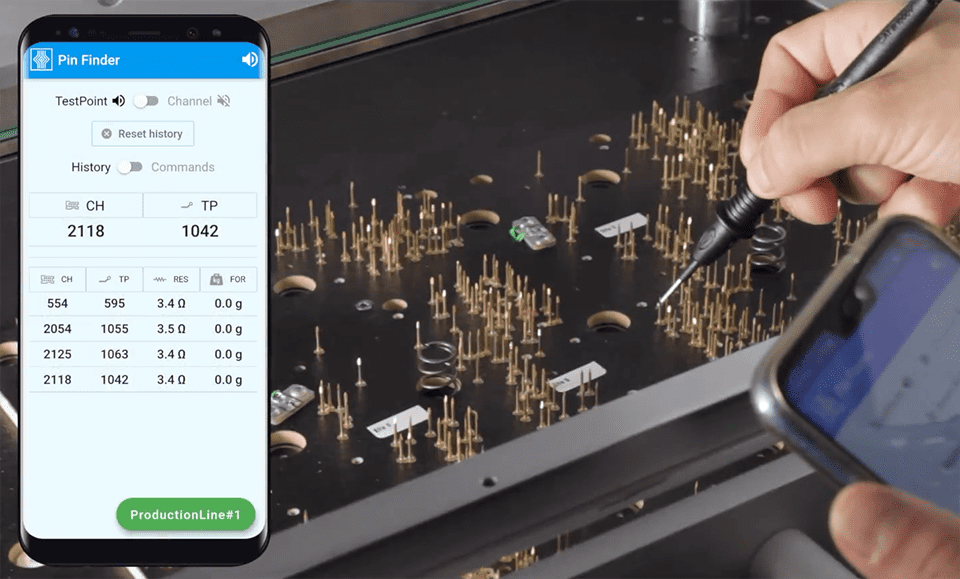

Faster fixture’s pogo pins diagnostic with the Pin Finder App

- The Pin Finder App is a mobile application that makes pogo pins and tester’s channel integrity verification faster and easier.

- The app allows you to carry out the pogo pins’ diagnostics without having to remove the fixture from the tester.

- By probing each pogo pin and viewing the measured data via the Pin Finder App, you can quickly verify each channel by measuring its resistive value and associated test point.

- The app displays the pogo pins’ information in real-time. It also features a text-to-speech function to ease the diagnostic operations and avoid looking at the smartphone screen at each measurement.

Easy. Fast. Self-programming

- Minimized application development costs: automatic generation of the file for fixture drilling and wiring.

- Automatic test program generation in minutes.

- Real time production monitoring and analysis.

- Automatic CAD data recognition & import.

- User-friendly intuitive graphical interface.

- Automatic test report generation.

- Automatic debug & tuning.

- Easy diagnostic of fixture’s pogo pins via mobile app.

- Parallel programming of different-type ICs.

- 4x throughput with 4-Core Architecture.

- Automatic test program generation.

- Ultra-fast handling in 3 sec..

- No operator cost.

- 5000+ tests/sec.

SPEA has designed and manufactured a new series of Automatic PCB handling Equipment, able to perform autonomous loading and unloading operations. SPEA Board Handling Equipment is available in modular configurations, which allow for quick changes on field, and stand out for their reduced footprint, as they take up just one third of the floor space typically needed by traditional PCB handling equipment.

- The modular architecture allows you to choose each handling equipment for custom-tailored configurations. It is possible to add, swap and move each handling equipment within the same test cell or other ones; or to change the loading mode (pass-back, pass-through, mixed), to satisfy at any time the requirements of current and future production.

- All of this comes in small-sized equipment that take up just 1/3 of the floor space typically needed by traditional board handling equipment. The smallest handling equipment has a footprint of just 0.70m2, and a typical pass-through configuration takes up as little as 1.31m2 – compared to 3.38m2 with traditional automation.

- Rack positioning can be performed manually or automatically in different ways, for example using AGV, Robot, Conveyor or Local Magazine Buffer. The rack positioning height is programmable to ease operator loading operations, or to correctly set up Robot or AGV rack loading.

- The SPEA Automatic Board Handling Equipment has been conceived with a compact-size and modular architecture to provide a cost-effective and space-saving product.

| Brand |

SPEA |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.