KOKI Leaded Soldering Paste

KOKI leaded soldering paste Printing Performance

Key Features of KOKI Leaded Solder Paste

- Excellent wetting on various surfaces

- Uniform and stable printing with no stencil clogging

- Stable rheology with consistent viscosity during long print runs

- Low spattering and minimal solder balling during reflow

- Long stencil life for continuous production

- High environmental stability and slow drying behavior

KOKI leaded soldering paste, Superior workability, solderability and electrical reliability.

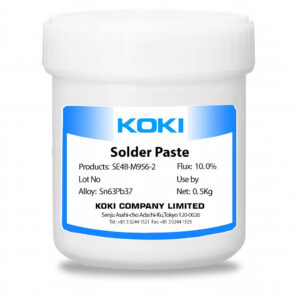

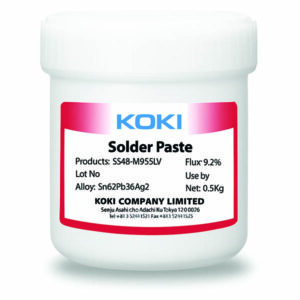

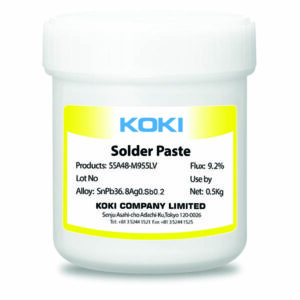

KOKI Soldering Materials – Available in 3 alloy:

- Regular leaded solder paste – Sn63Pb37

- Leaded with 2% Ag solder paste – Sn62Pb36Ag2

- Antimuon (Sb) Solder Paste – Sn62.6Pb36.8Ag0.4Sb0.2

Top Advantages for SMT Production Lines - Stencil Printing Solder Paste KOKI

- Reduced printing defects such as bridging, cold joints, and solder balling

- Ideal for fine-pitch components including 0402, 0201, and BGA

- Outstanding performance on high-speed SMT lines with no special adjustments

- Reduced line downtime due to less stencil cleaning

- Improved overall yield and final assembly quality