JUKI JM-E01 – THT SMT Solution | Automatic Insertion Machine

JUKI-JM E01 THT LINE – SMT Line Solution

- High-precision insertion is realized by image recognition using inspection machine technology.

- Wide component range from small to large and heavy.

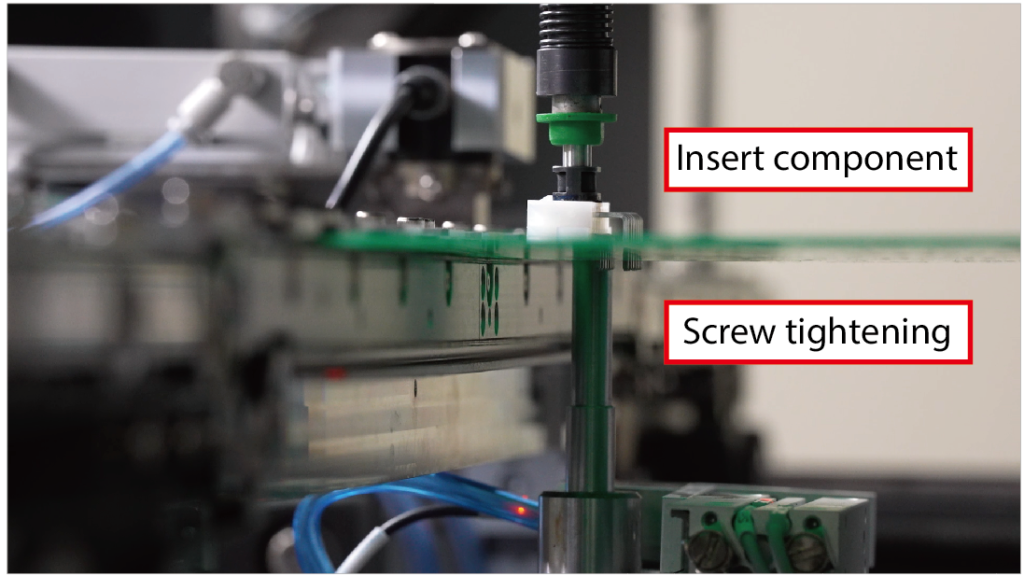

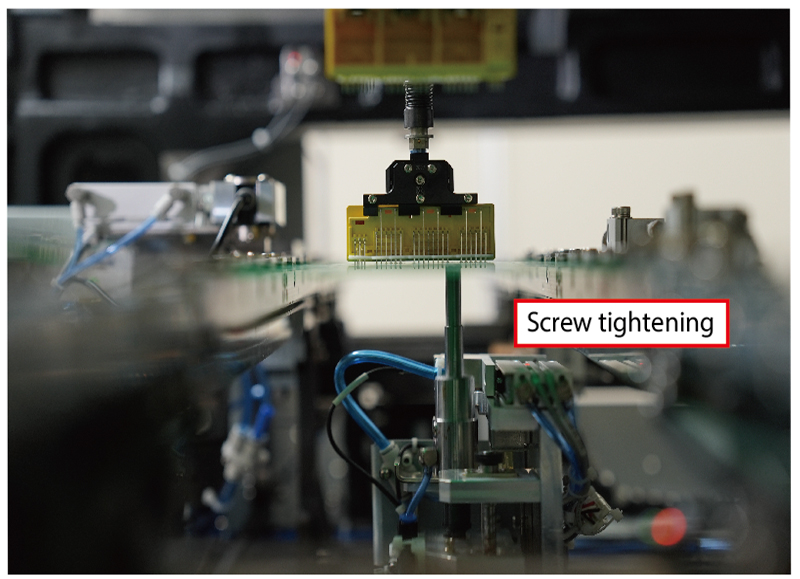

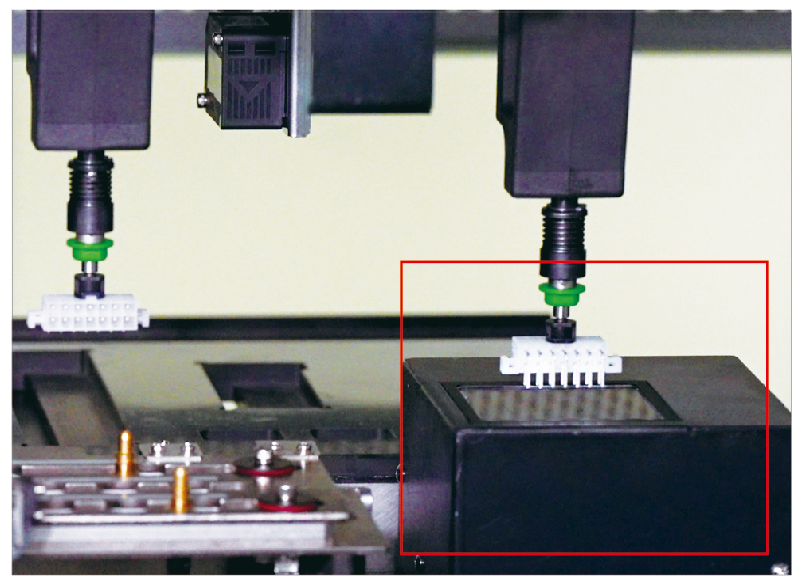

- One unit can insert component and screw tightening.

- Component insertion×Screw tightening.

- Automate 2 processes simultaneously.

- A further evolved Multitask Platform.

JUKI JM-E01 THT LINE

JUKI JM-E01 THT LINE highly versatile machine realizes component inserting work, screw fastening work, multi-process automation the weight is up to 10kg*².

High efficiency

One Unit Can Insert Component and Screw Tightening

This highly versatile machine realizes component inserting work, screw fastening work, and multi-process automation. The board size is 800mm x 560mm*¹, and the weight is up to 10kg*².

One Unit Can insert Component and Screw Tightening

*1 At double feed: standard

*2 Option

High Flexbility

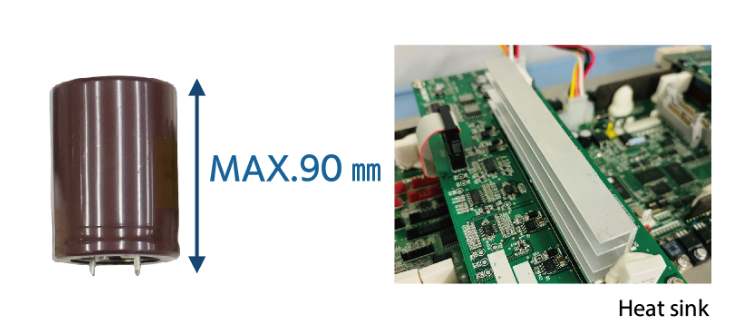

Wide Component Range from Small to Large and Heavy

XY shaft construction adopted. By setting head unit axis to 2 axes, the compatible component size has been expanded. Component height is 90mm*, component heavy 400g, and insertion force up to maximum 50N.

*Component body 80㎜ or less, lead + body = 90㎜ or less\

Supports Large and Heavy Component

- Component size : Max. 150.0㎜

- Component height : Max. 90㎜*

- Component weight : Max.400g

- *Component body 80㎜ or less, lead + body = 90㎜ or less

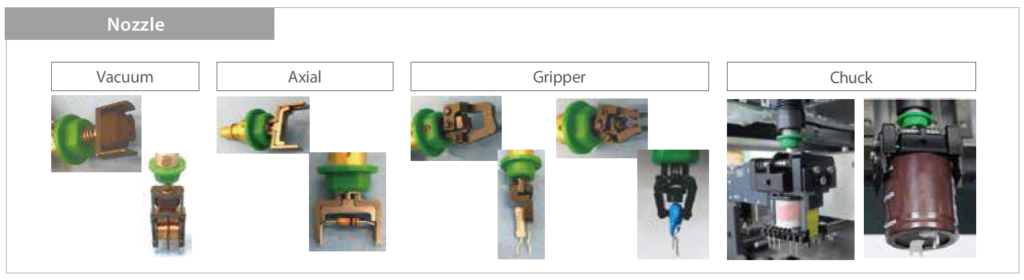

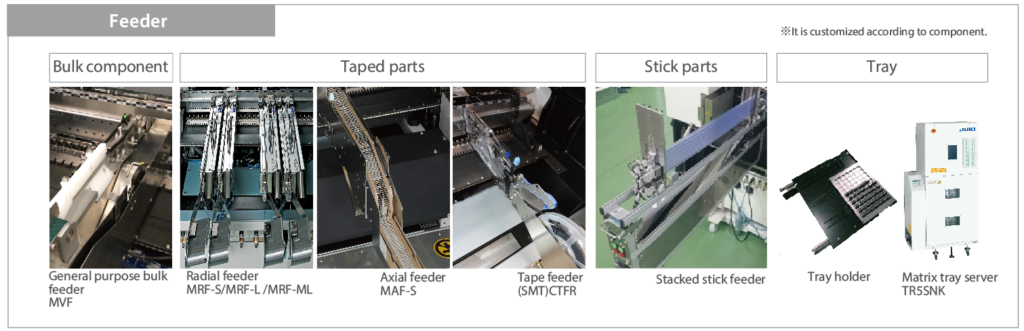

Large variety of feeders and nozzles

High quality

High-precision insertion is realized by image recognition using inspection machine technology

By applying JUKI’s unique 3D image-recognition technique, the leading edge of the lead can be recognized more accurately. It also enables lead recognition with a pointed tip, semicircular tip, and difference in height, enabling high-precision insertion of a wide range of insertion component.

Prevents scratches and misalignment of PCB and component

Screws can be tightened from under the board. Since the board does not need to be turned over, it prevents scratches and misalignment on the board and component and reduces losses.

3D inspection

Features of the Vision Centering

JUKI’s unique component centering systems.

Dual centering methods (Laser or Vision)

Flexibility

Vision centering technology

method can be selected based on component type, shape, size and material. Laser centering is used for high speed placement of smaller components. Vision is used when lead or ball inspection is needed or when the component is too large for the laser. Many nozzles are available for odd-shaped components providing unsurpassed component handling.

General Vision

General vision function is used to support a wide variety of today’s unusual vision centered components. After programming is complete, the data can be verified by picking and test centering a component.

| Model | JM-E01 |

| Board size (㎜) | 1Single clamping:50×50~410×560 Double clamping:50×50~800×560 |

| PCB weight | 6kg(standard)10㎏(option) |

| Component height | Component body 80㎜ or less, lead + body = 90㎜ or less |

| Component size(mm) | Outer dimension (package) size 150mm Recognition size once:40×25, 4×1:150×25, 4×2:150×48, 4×3:150×71 |

| Applicable screw size | M3 size |

| Screw supply method | Force-feed type |

| Machine dimension(mm) (W×D×H) | 1,500×1,930×1,600 |

| Body weight | 2,000kg |

| Brand | JUKI |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.