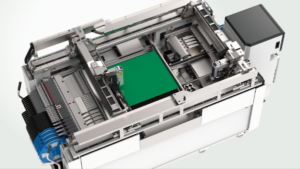

FUJI AIMEXR Full Automatic | Pick and Place Machine

FUJI AIMEXR | SMT Pick and Place Machine

- FUJI Pick and Place Machine Full Automatic This high end model machine supports the latest functions that support various production types flexibly on an advanced platform.

- The fastest in the history of the series.

- Further expanded capability.

- High quality placement.

- Stable operation.

FUJI AIMEXR Pick and Place

- The AIMEXR achieves fast placement with 20 percent shorter cycle time – and this with the highest quality, supported by new real-time sensor technology In combination with the latest placement heads, high-performance placement is ensured This results in high throughput and accuracy in production.

- In addition, the solution enables uninterrupted operation. At the same time, it reduces energy consumption by around ten percent compared with predecessor solutions.

FUJI AIMEXR | SMT Pick and Place Machine

- This machine is strong in flexible production such as NPI support for starting new production quickly and immediate support for production type change with batch changeover.

- It inherits versatility which is a feature of the AIMEX series and features high productivity including high quality and mass production with new sensing functions.

- This high end model machine supports the latest functions that support various production types flexibly on an advanced platform.

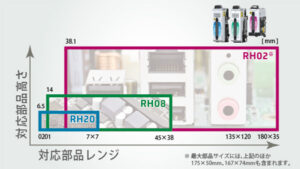

Further expanded capability

Even though the machine size is compact, it is also flexible and a wide range of production operation is possible with the machine’s extensive capacity.

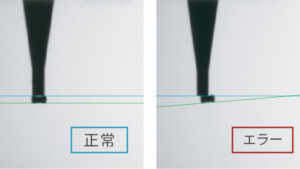

High quality placement

Always maintain correct placement by checking the conditions of electronic parts and panels using real time sensing technology and then reflecting check results to the machine. This maintains stable placement quality.

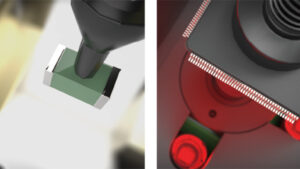

Stable operation

Support for production that enables non-stop operation and quick recovery. This can help minimize line stoppage, improving operation rates.

AIMEXR saves log and image data automatically. Resolutions can be reached quickly whenever problems occur by making use of this information.

If there is a network problem, production can be continued using the program information stored inside the machine. This yet-to-be-released feature will make it possible to avoid sudden stops at the production line.

You must be logged in to post a review.

Reviews

There are no reviews yet.