Home » Products » SMT Line Machine » Reflow Oven » TRN II-E93M | TSM | Reflow Soldering Oven

TRN II-E93M | TSM | Reflow Soldering Oven

TRN II-E93M | TSM | Reflow Soldering Oven

- Excellent Thermal management thru RTPM(Real-time Thermal Profile Management)

- Maintenance-free design

- Unbeatable Cost of Ownership

- PSA built-in type, Dual Flux Management System availabl

Category: Reflow Oven

Tags: Reflow oven, TRN II-E93M, TSM

Description

TRN II-E93M | TSM | Reflow Soldering Oven

TSM – TRN II-E93M

- Constant innovation for the best Reflow

- TRN Series, the top-level model to realize Econology and Humanism, pursued by TSM

- Deliver our cutting-edge technology and best product performance to our valuable customers all the time

The very best of Nitrogen Reflow Oven in every aspects of soldering quality, energy saving, flux recovery

Achieved the industry’s lowest N2 consumption level

- Realize Flux Zero in OVEN -> equip FMS applied with patent technology

- Thermal Interference Innovation in each zone -> Able to set up temperature difference with 60ºC in max. of interzone

- Internal Heat Reduction of Reflow -> apply New Emission System

- Real-time Monitoring (optional)

- Real-time Temperature Profile Monitoring (RTPM)

- Real-time Oxygen Concentration Monitoring in each zone (RPPM)

- Conveyor Vibration Monitoring

- Monitoring a number of rotations of Blower Motor

- Circulation Temperature Monitoring of FMS

- Output Monitoring of Heater Control

- Alert of Conveyor Chain Oil Level

- Alert of Dust Collection Flux Level

- Reduction of N₂ consumption with more than 20% compared to previous models (fan size / change of perforated plate)

- Improved ppm performance with more than 30% compared to previous models (curtain shutter applied)

- The very best of Nitrogen Reflow Oven in every aspects of soldering quality, energy saving, flux recovery

- Achieved the industry’s lowest N2 consumption level

- Excellent Thermal management thru RTPM(Real-time Thermal Profile Management)

- Maintenance-free design

- Unbeatable Cost of Ownership

- PSA built-in type, Dual Flux Management System available

- Ensures the machine cleaner and soldering quality

- Industry’s lowest operational cost from high energy efficiency

- Lowest Downtime and Maximized productivity

- World-best Brand Core components like Omron PLC, Fuji Inverter

- Specially treated steel structure to prevent the distortion from the heat

- Overheat Alarm sensors for Blower Motor

- Multi-zone Air Cooling standard, Water cooling optional

- Minimizes heat loss and results in low power consumption

- Powerful performance of FMS ever before with double sized capacity of FMS installation (2×8=>2x12A)

| Machine Brand / Model | Tsm |

| Model | TSN II E93M |

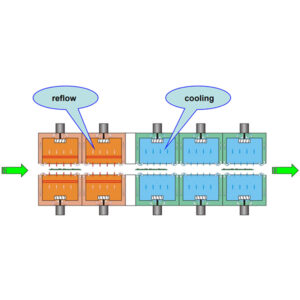

| Heating Zone Top | 9 |

| Heating Zone Bottom | 9 |

| Heating Total Length | 2980mm |

| Width Standard | 410mm |

| Width Option | 550mm |

| Atmosphere | Air/N2 |

| Max Temp | 350 °C |

| Cooling Zone | 3 |

| Cooling Zone Length | 310 |

| Cooling Total Length | 1080 |

| Conveyor Speed | 30 – 160 Cm / Min |

| Conveyor Type | Chain/Mesh/Support |

| Power Consumption | 70kW –> 10 kW |

Additional information

| Brand |

TSM |

|---|

Reviews (0)

Be the first to review “TRN II-E93M | TSM | Reflow Soldering Oven” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.