Fuji Screen printing machine

NXTR-PM Smart Factory Platform Stencil Printer | FUJI

- Fuji Screen printing machine By creating optimum production schedules using the Fuji system, and linking with other machines in the line, it is possible to achieve stable production.

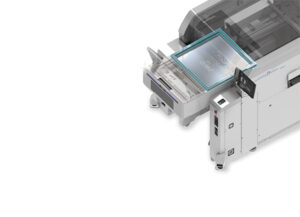

- NXTR PM is a printer that embodies the NXTR concept of reducing line size, high area productivity, front operation, and ease of use.

- Various data is collected within the machine, which can then be used to maintain quality and the state of the machine.

- It is built to support wide panel and frame sizes, and has the capability to print delicate solder patterns.

Support for evolving placement processes

Fuji Screen printing machine is possible to automatically exchange screen masks and backup blocks by using PM Smart Changer.

Setting materials in the PM Smart Changer rack in advance makes it possible to automatically change the materials when changing the production model.

Changeover work such as collecting and supplying solder when exchanging screen masks, changing the conveyor width, and positioning backup blocks can be automated.

This reduces the workload on operators and eliminates reworking that may result from human error.

Automatic extraction of print parameters from the database makes it possible to quickly determine printing conditions and start production without test printing.

It is no longer necessary to look for past performance records and adjust parameters from experience.

This helps to minimize the time until the start of production.

This system is also designed for referencing past quality records from SPI machines, to provide the option of selecting more suitable printing conditions.

Support for various production types

Single lane and dual lane production is supported by a single machine accordingly to fit any situation.

All kinds of production are flexibly covered; from producing small panels for smartphones to large panels associated with automotive electronics and network infrastructure.

The NXTR PM supports dual lane production and is highly compatible in line configurations with the NXTR.

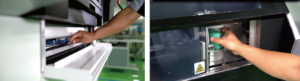

Solder cups and cleaning paper are accessible from the machine front during production for easy exchange.

Equipped with the solder transport mechanism*, the machine transports solder to printing positions during dual lane production.

These features ensure non-stop production in good harmony with material supply.

Fuji Screen printing machine

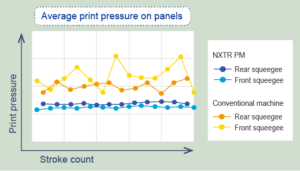

Based on inspection result feedback from SPI machines, automatic offsetting is implemented in the printing conditions based on a prediction of future printing problems such as solder volume deviations, misalignment, and smearing.

This helps maintain high quality printing.

High quality printing

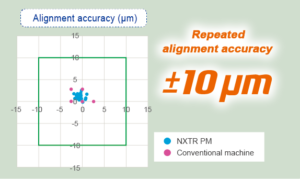

Better responsiveness to positioning the mask results from the lighter-weight offsetting mechanism with reduced sliding resistance in addition to advanced image recognition accuracy for fine marks that is driven by the high resolution camera.

This brings a high level of alignment performance with stable printing quality.

Support for evolving placement processes

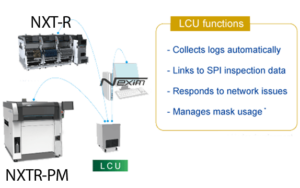

By automatically saving logs and image data, issues that may cause machine stops and information that can be used for problem solving are not missed, for faster recovery times.

Furthermore, network conditions are constantly monitored to prevent production stops associated with network issues from occurring.

| Repeated alignment accuracy 1 | ±0.010 mm @6σ (CPK ≥ 2.0) | |||

| Printing accuracy 2 | ±0.020 mm @6σ (CPK ≥ 2.0) | |||

| Printing speed | 1 to 300 mm / sec. | |||

|

Panel size (L x W)

|

Single conveyor | 48 x 48 to 610 x 610 mm | ||

| Double conveyor | Single conveyance | 48 x 48 to 610 x 510 mm | ||

| Dual conveyance | 48 x 48 to 330 x 280 mm | |||

| Screen frame (L x W) | 650 x 550 mm, 29 x 29-inch, 750 x 750 mm, 750 x 810 mm | |||

| Machine size (L x W x H) | 1,280 x 1,700 x 1,480 mm | |||

| Power | 3-phase AC 200 to 230 V ±10% (50/60 Hz) | |||

| Air | 0.4 MPa | |||

| Air consumption | Single conveyor | 7.7 L/min. (ANR) | ||

| Double conveyor | 37.0 L/min. (ANR) | |||

| برند |

FUJI |

|---|

نقد و بررسیها

هنوز بررسیای ثبت نشده است.